Festo Контроллер двигателя CMMD-AS User Manual

Page 78

4. Functional safety engineering

78

Festo P.BE-CMMD-AS-HW-EN 1002NH

Among other issues, the EN 60204-1 standard deals with the handling of emergencies and

defines the terms EMERGENCY OFF and EMERGENCY STOP (see table).

Handling

Definition (EN 60204-1)

Danger case

EMERGENCY

OFF

Electrical safety in case of emergency by

switching off the electrical energy to all or

part of the installation.

EMERGENCY OFF is to be used where a risk

of electric shock or other electrical risk

exists.

EMERGENCY-

STOP

Functional safety in an emergency by

bringing a machine or movable parts to

a standstill.

EMERGENCY STOP is used to stop a process

or a motion if this creates a danger.

Table 4.1 EMERGENCY OFF and EMERGENCY STOP as per EN 60204-1

The standard EN 61800-5-2 describes various safety functions that can be used

dependent on the application.

For the position controllers of the CMMD-AS family, the STO and SS1 safety functions

have been implemented through external circuitry.

Galvanic isolation does not occur with the STO function. As a result, this does not have

any protective function against electric shock. In the sense of the standards, an

EMERGENCY-OFF system cannot be implemented with the STO, because this requires the

complete system to be switched off via a mains power isolator of some kind (main power

switch or mains circuit breaker).

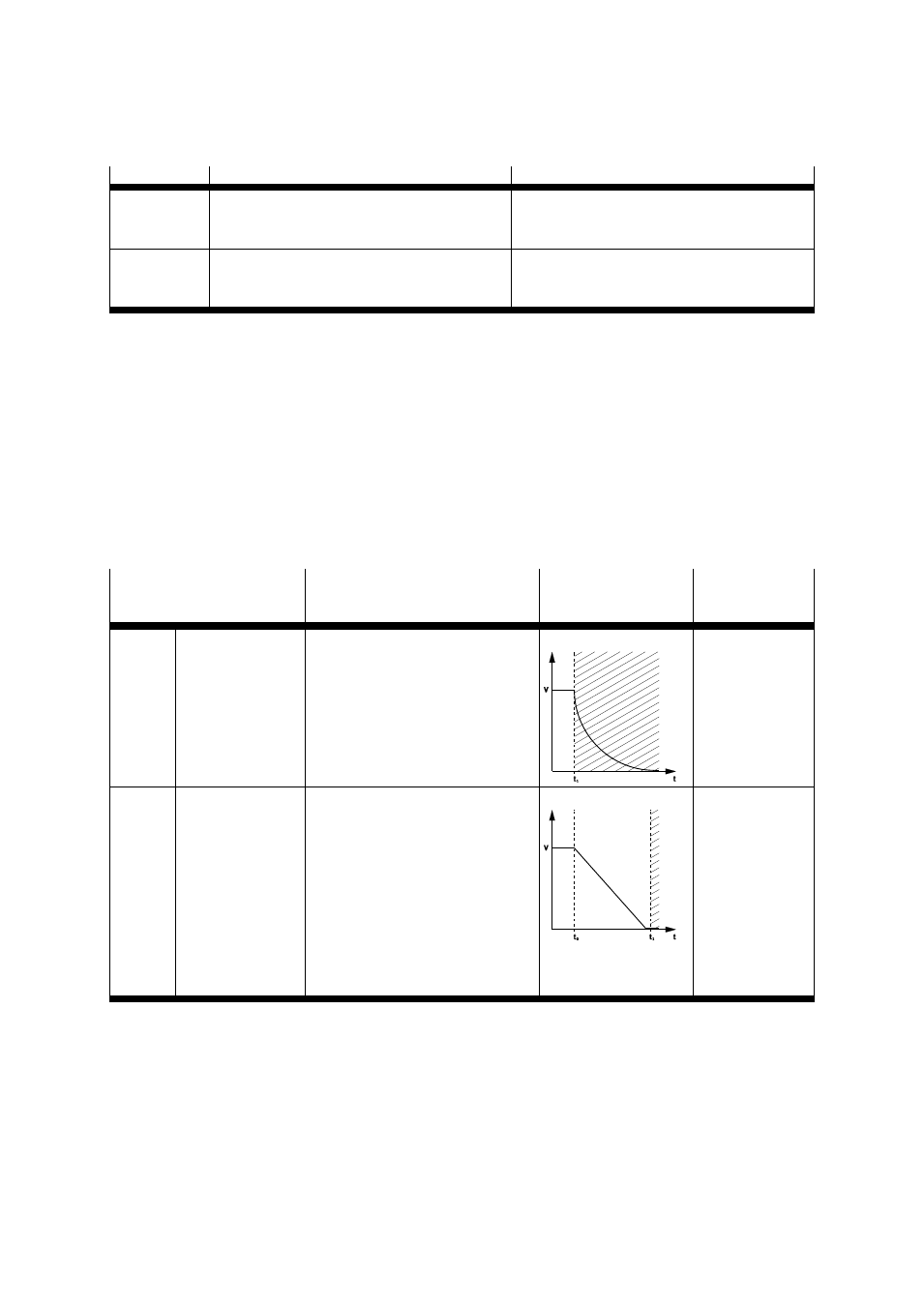

Safety function as per

EN 61800-5-2

PILZ component

Switch-off behaviour Stop category in

accordance with

EN 60204-1

STO

Safe Torque Off

PNOZ X2P

Relay outputs forced:

- 2 safety contacts no delay

Connection options for:

- EMERGENCY STOP buttons

- Protective door limit switches

- Start button

0

SS1

Safe Stop 1

PNOZ XV2P

Relay outputs forced:

- 2 safety contacts no delay

- 2 safety contacts relapse

delayed

Connection options identical

to X2P

Fixed or adjustable relapse delay

Cancelling the time delay through

Reset button

1

Table 4.2 Overview of the safety function in accordance with EN 61800-5-2