5 parameters, P549 pot box function, P550 back up data record – NORD Drivesystems BU0500 User Manual

Page 127: P551 drive profile

5 Parameters

BU 0500 GB-1013

127

P549

Pot Box function

(PotentiometerBox function)

S

0 ... 16

{ 0 }

In this parameter, the setpoint of the PotentiometerBox (SK TU3-POT) is assigned with a

function. (An explanation can be found in the description of P400.)

As of software version 1.7 R0, on setting 4 or 5, the ControlBox or the ParameterBox are also set

to function as suppliers of auxiliary setpoints. (see Section 0)

0 = Off

1 = Setpoint frequency

2 = Torque current limit

3 = Actual frequency PID

4 = Frequency addition

5 = Frequency subtraction

6 = Current limit

7 = Maximum frequency

8 = Actual PID frequency limited

9 = Actual PID frequency monitored

10 = Servo mode torque

11 = Torque precontrol

12 = Reserved

13 = Multiplication

14 = Process controller actual value

15 = Process controller setpoint

16 = Process controller lead

Pos : 313 /Anleit ungen/5. / 6. Parametrier ung [BU 0500 / BU 0200]/ Par ameter/ P500-P599/ Paramet er P550 – C ontrol Box Auf träge @ 0\mod_1328098468764_388. doc x @ 12031 @ @ 1

P550

Back up data record

(Back up data record)

0 ... 3

{ 0 }

Within the optional ControlBox it is possible to save a data set (parameter set 1 … 4) of the

connected FI. This is saved in a non-volatile memory within the Box, and can therefore be

transferred for other SK 5xxE units with the same database version (see P742).

0 = No change

1 = FI

à ControlBox, the dataset is written from the connected FI to the ControlBox.

2 = ControlBox

à FI, the dataset is written from the ControlBox to the connected FI.

3 = FI

ßà ControlBox, the FI dataset is exchanged with the ControlBox dataset. With this

variant, no data is lost. It is continuously exchangeable.

NOTE:

If parameterisation from old FI's need to be loaded into FIs with new software (P707),

then the ControlBox must previously be written to by the new FI (P550 = 1). The

dataset to be copied from the old FI can then be read out and copied to the new FI.

Pos : 314 /Anleit ungen/5. / 6. Parametrier ung [BU 0500 / BU 0200]/ Par ameter/ P500-P599/ Paramet er P551 – Antriebs profil @ 0\ mod_1328098517139_388. doc x @ 12054 @ @ 1

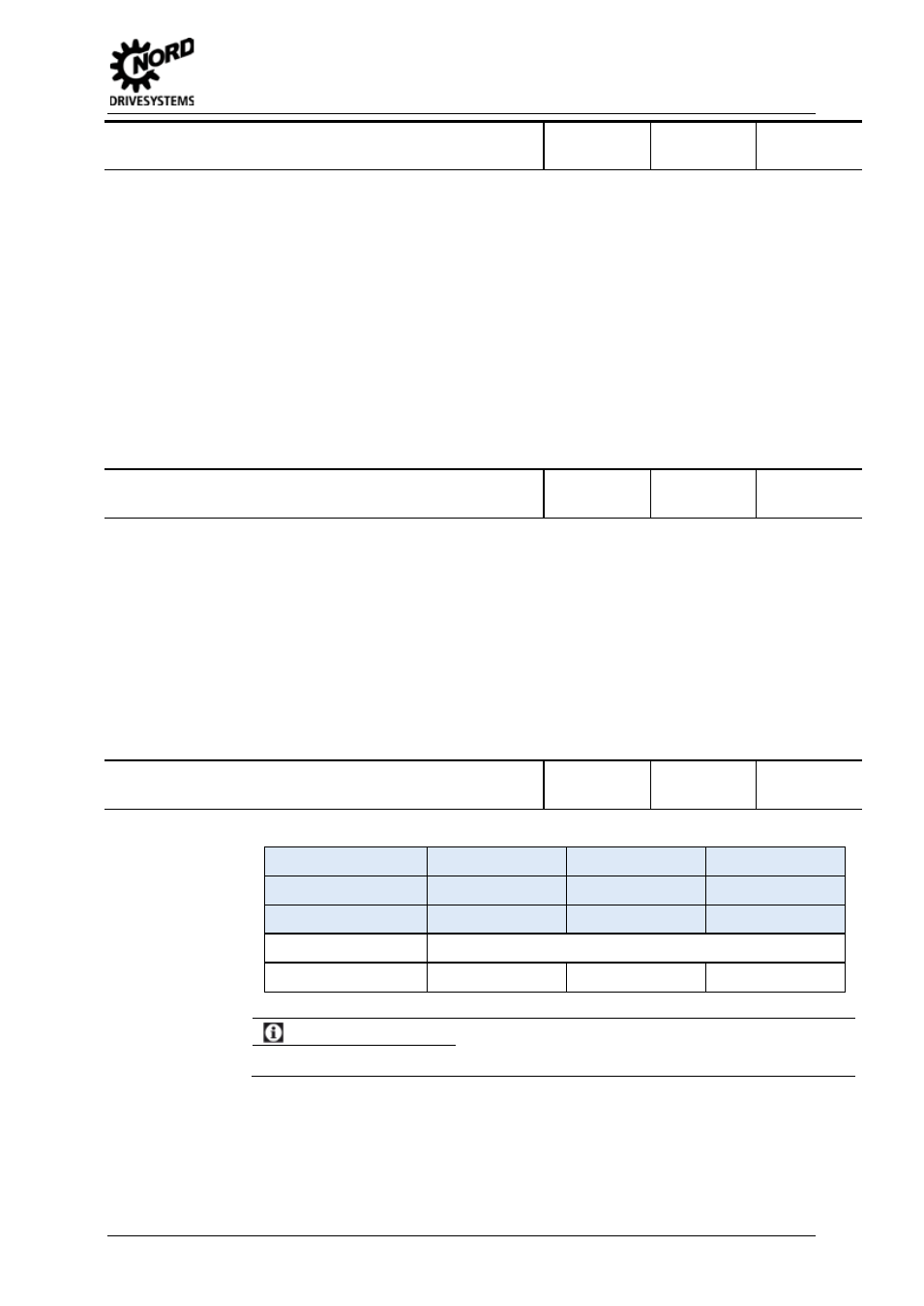

P551

Drive profile

(Drive profile)

S

0 … 1

{ 0 }

According to the option the relevant process data profiles can be activated with this parameter.

Note

Activation of profiles

This parameter is only effective for pluggable technology modules (SK TU3-…).

System

CANopen

DeviceNet

InterBus

Technology module

SK TUx-CAO

SK TUx-DEV

SK TUx-IBS

Setting

0 = OFF =

USS protocol (Profile "Nord")

1 = ON =

DS402 profile

AC Drives profile

Drivecom profile

Pos : 315 /Anleit ungen/5. / 6. Parametrier ung [BU 0500 / BU 0200]/ Par ameter/ P500-P599/ Paramet er P552 – C AN M ast er Z ykl usz eit @ 0\ mod_1328098574264_388. doc x @ 12077 @ @ 1