Safety instructions, Safety instructions 1.1 software history, 2 intended use – KROHNE OPTISONIC 6300 EN User Manual

Page 6: 3 certification

1

SAFETY INSTRUCTIONS

6

OPTISONIC 6300

www.krohne.com

07/2009 - 4000263902 - HB OPTISONIC 6300 R03 en

Safety instructions

1.1 Software history

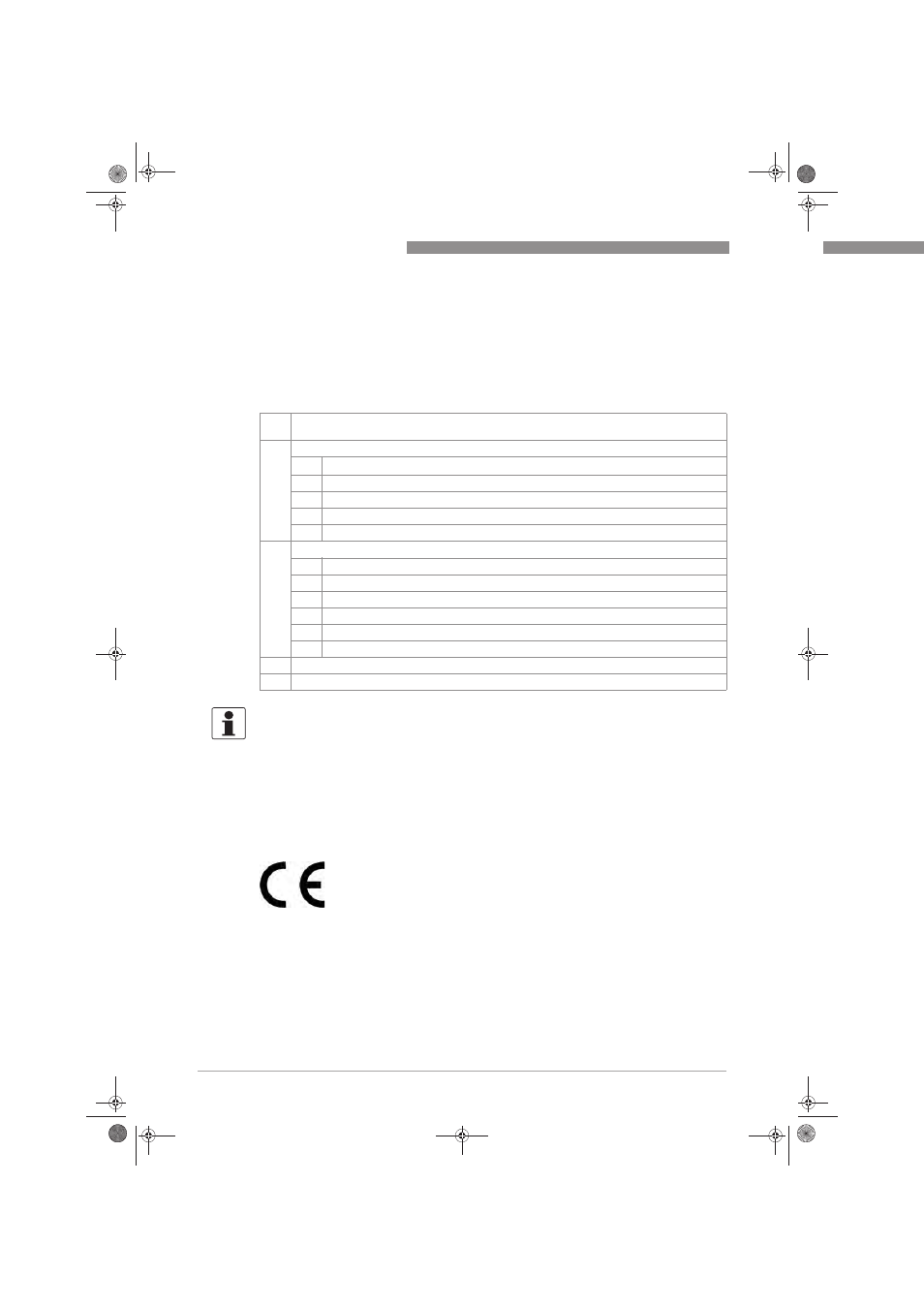

For all GDC devices, the "Electronic Revision" (ER) is consulted to document the revision status

of the electronics according to NE 53. It is easy to see from the ER whether any fault repairs or

major changes to the electronic equipment have taken place and what effect they have had on

compatibility.

Changes and effect on compatibility

1.2 Intended use

The overall functionality of the clamp-on flowmeter is the continuous measurement of actual

volume flow, mass flow, flow speed, velocity of sound, gain, SNR and diagnosis value.

1.3 Certification

In accordance with the commitment to customer service and safety, the device

described in this document meets the following safety requirements:

• EMC Directive 89 / 336 / EEC and 93 / 68 / EEC in conjunction with EN 61326-1 (1997) and A1

(1998), A2 (2001)

• Low-Voltage Directives 73 / 23 / EEC and 93 / 68 / EEC in conjunction with EN 61010-1 (2001)

1

Downwards compatible changes and fault repair with no effect on operation (e.g. spelling

mistakes on display)

2-_

Downwards compatible hardware and/or software change of interfaces:

H

HART

®

P

PROFIBUS

F

Foundation Fieldbus

M

Modbus

X

all interfaces

3-_

Downwards compatible hardware and/or software change of inputs and outputs:

I

Current output

F, P

Frequency / pulse output

S

Status output

C

Control input

CI

Current input

X

all inputs and outputs

4

Downwards compatible changes with new functions

5

Incompatible changes, i.e. electronic equipment must be changed.

INFORMATION!

In the table below, "x" is a placeholder for possible multi-digit alphanumeric combinations,

depending on the available version.

.book Page 6 Tuesday, August 18, 2009 4:51 PM