A1.2.6 repair and replacement, A1.2.7 startup time, A1.2.8 firmware update – Yokogawa ADMAG AXR User Manual

Page 187: A1.2.9 reliability data, A1.2.6, A1.2.7, A1.2.8, A1.2.9, A1-2

A1-2

IM 01E30D01-01EN

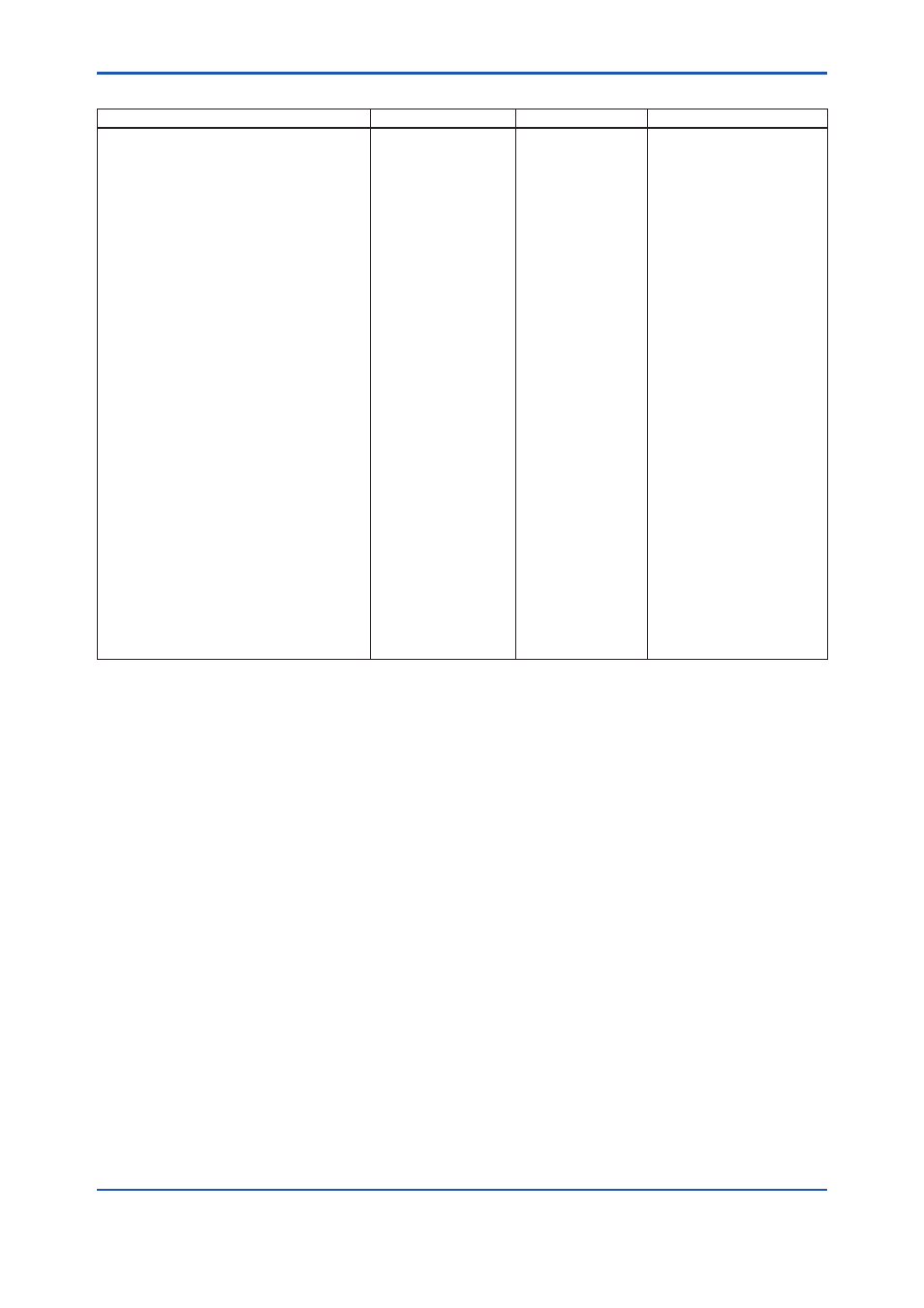

Table A1.2 Proof Testing

Testing method

Tools required

Expected outcome

Remarks

Analog Output Loop Test and Calibration

1. Bypass the safety PLC or the final

element interface or take other

appropriate action to avoid a false trip.

●Analog Output Loop Test:

2. Send a HART or BRAIN command to

the Magnetic Flowmeter to go to the

high alarm current output and verify that

the analog current reaches that value

and verify that discrete contact has de-

energized (if used)

3. Send a HART or BRAIN command to

the Magnetic Flowmeter to go to the low

alarm current output and verify that the

analog current reaches that value.

4. Use the HART or BRAIN communicator

to view detailed device status to ensure

no alarms or warnings are present in the

Magnetic Flowmeter.

5. Perform reasonability check on the

sensor value(s) versus an independent

estimate (i.e. from direct monitoring of

BPCS value) to show current reading is

good.

●Calibration

6. Verify the measurement for two flow

points.

7. Restore the loop to full operation.

8. Remove the bypass from the safety PLC

or otherwise restore normal operation.

• BT200

• HART configuration

tool

Proof Test Coverage

=96%

The output needs to be

monitored to assure that

the Magnetic Flowmeter

communicates the correct

signal.

A1.2.6 Repair and Replacement

If repair is to be performed with the process online

the AXR will need to be bypassed during the

repair. The user should setup appropriate bypass

procedures.

In the unlikely event that the AXR has a failure, the

failures that are detected should be reported to

Yokogawa.

When replacing the AXR, the procedure in the

installation manual should be followed.

The personnel performing the repair or replacement

of the AXR should have a sufficient skill level.

A1.2.7 Startup Time

The AXR generates a valid signal within 10 second

of power-on startup.

A1.2.8 Firmware Update

In case firmware updates are required, they

will be performed at factory. The replacement

responsibilities are then in place. The user will not

be required to perform any firmware updates.

A1.2.9 Reliability Data

A detailed Failure Mode, Effects, and Diagnostics

Analysis (FMEDA) report is available from

Yokogawa with all failure rates and failure modes.

The AXR is certified up to SIL2 for use in a simplex

(1oo1) configuration, depending on the PFDavg

respectively PFH calculation of the entire Safety

Instrumented Function.

The development process of the AXR is certified up

to SIL3, allowing redundant use of the transmitter

up to this Safety Integrity Level, depending the

PFDavg respectively PFH calculation of the entire

Safety Instrumented Function.

When using the transmitter in a redundant

configuration, the use of a common cause factor

(β-factor) of 5% is suggested. If the owner-operator

of the plant would institute common cause failure

training and more detailed maintenance procedures

for avoiding common cause failure, a beta factor of

2% would be applicable.