Yokogawa ADMAG AXR User Manual

Page 167

12-15

IM 01E30D01-01EN

<12. OUTLINE>

Item

Specifications

Applicable

Model

Code

General

Explosion

proof

A

XR

**

*G

A

XR

**

*C

Five-point

Calibration in

User-specified

Span (*9)

A flow test near 0, 25, 50, 75, and 100% of the user-specified span is performed

instead of the standard flow test and a test certificate (QIC) is submitted. Specify the

span flow rate and unit when placing an order.

Specify the span (100% flow span) whose corresponding flow velocity lies between

1.0 to 10 m/s and that is less than the maximum line capacity. Selectable range of

flow rate span is showing below.

Size: mm (in.)

Selectable range of flow rate span: m

3

/h

(Flow rate span velocity: m/s)

25 (1)

1.77 (1.0) to

11 (6.22)

40 (1.5) 4.53 (1.0) to

28 (6.30)

50 (2)

7.07 (1.0) to

56 (7.92)

65 (2.5) 12.0 (1.0) to

80 (6.70)

80 (3)

18.1 (1.0) to 126 (6.96)

100 (4)

28.3 (1.0) to 190 (6.72)

150 (6)

63.6 (1.0) to 380 (5.97)

200 (8)

113 (1.0) to 670 (5.92)

○

○

SC

Bar-magnet for

operation of

magnet switches

(*6)

Bar-magnet for operation of magnet switches, with a case.

○

○

BM

FM Approval

FM Explosion proof

See “HAZARDOUS AREA CLASSIFICATION”

–

○

FF1

ATEX

Certification

ATEX Explosion proof

See “HAZARDOUS AREA CLASSIFICATION”

–

○

KF2

IECEx

Certification (*7)

IECEx Explosion proof

See “HAZARDOUS AREA CLASSIFICATION”

–

○

SF2

TIIS Certification

TIIS flameproof

See “HAZARDOUS AREA CLASSIFICATION”

(Need to select optional code G11 or G12.)

–

○

JF3

Flameproof

packing adapter

for TIIS Flame-

proof Type (*8)

One flameproof packing adapter and one blind plug.

–

○

G11

One flameproof packing adapter addition

–

○

G32

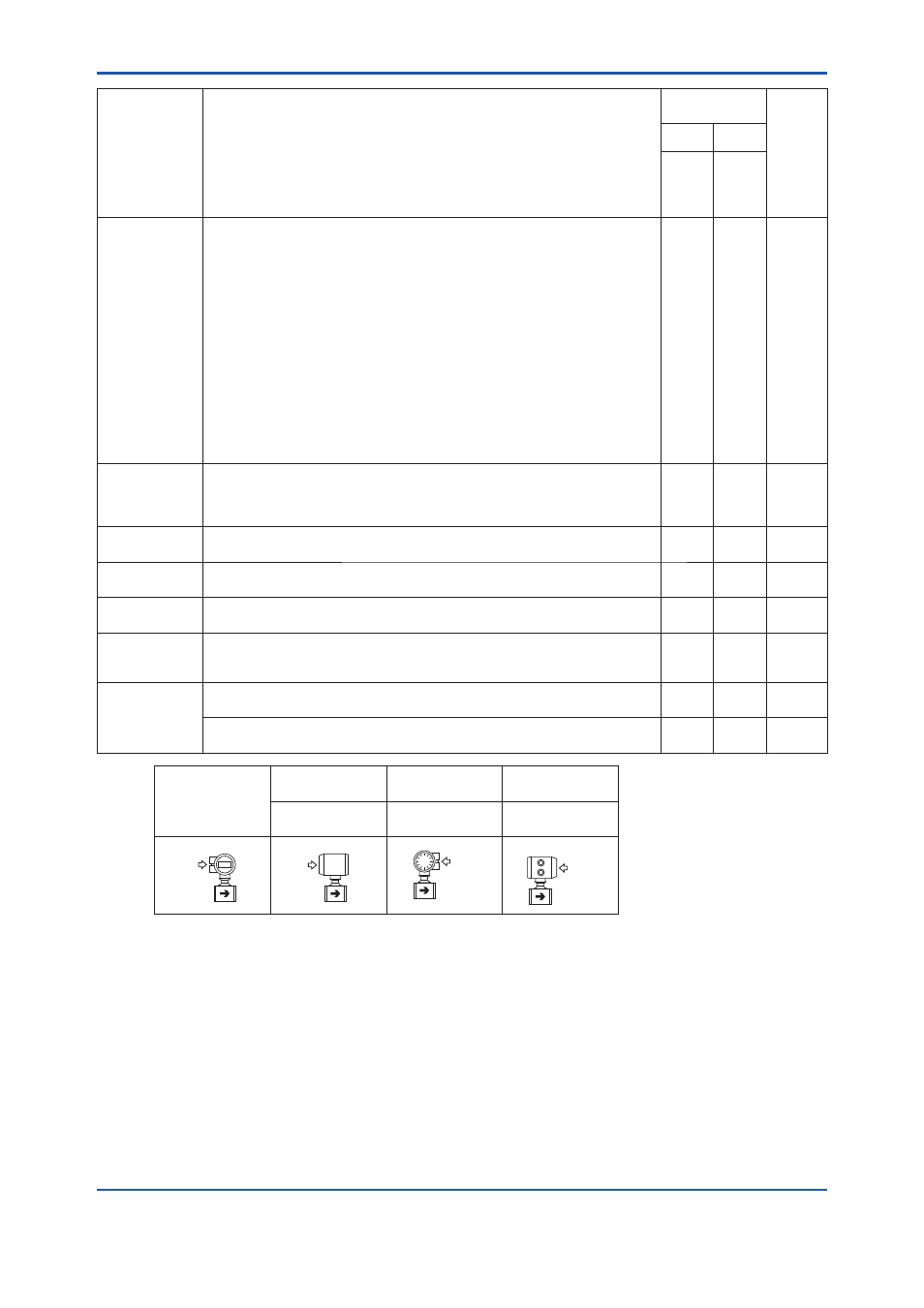

*1:

Standard

+90-degree

rotation

+180-degree

rotation

–90-degree

rotation

Optional Code

RA

Optional Code

RB

Optional Code

RC

Electrical Connection

Indicator

Electrical Connection

Indicator

*2: When specifying the optional code BCC or BSC, it is advisable to specify the optional code GA, GC, or GD at the same time to prevent

potential leakage caused by the difference in elasticity between the flowtube and chloroprene gaskets.

*3: Allowable temperature and pressure with the optional code BCC or BSC (only for Gaskets:

Chloroprene rubber) are equivalent to Valqua #2010.

*4: Allowable temperature and pressure with the optional code BCF or BSF (only for Gaskets:

PTFE-sheathed non-asbestos) are equivalent to Valqua #7030 (S).

*5: Refer to description of “Gasket” in the “Wetted Part Material”.

Special gaskets are inserted between the flowtube and the grounding ring or grounding electrode.

*6: Keep the bar-magnet in the case because of the powerful magnetic force.

*7: Applicable only for Australia, New Zealand, Singapore and India.

*8: For the TIIS flameproof type, select optional code G11 or G12. Available only for JIS G1/2 female electric connection.

*9: Standard flow test condition is follows;

- General-purpose use (25 to 200 mm)/ Exprosion proof type (25 to 100 mm): span; 2 m/s, test point; 0, 30, 100%

- Exprosion proof type (150, 200 mm): span; 2 m/s, test point; 0, 35, 100%