Caution – Yokogawa ADMAG AXR User Manual

Page 159

12-7

IM 01E30D01-01EN

<12. OUTLINE>

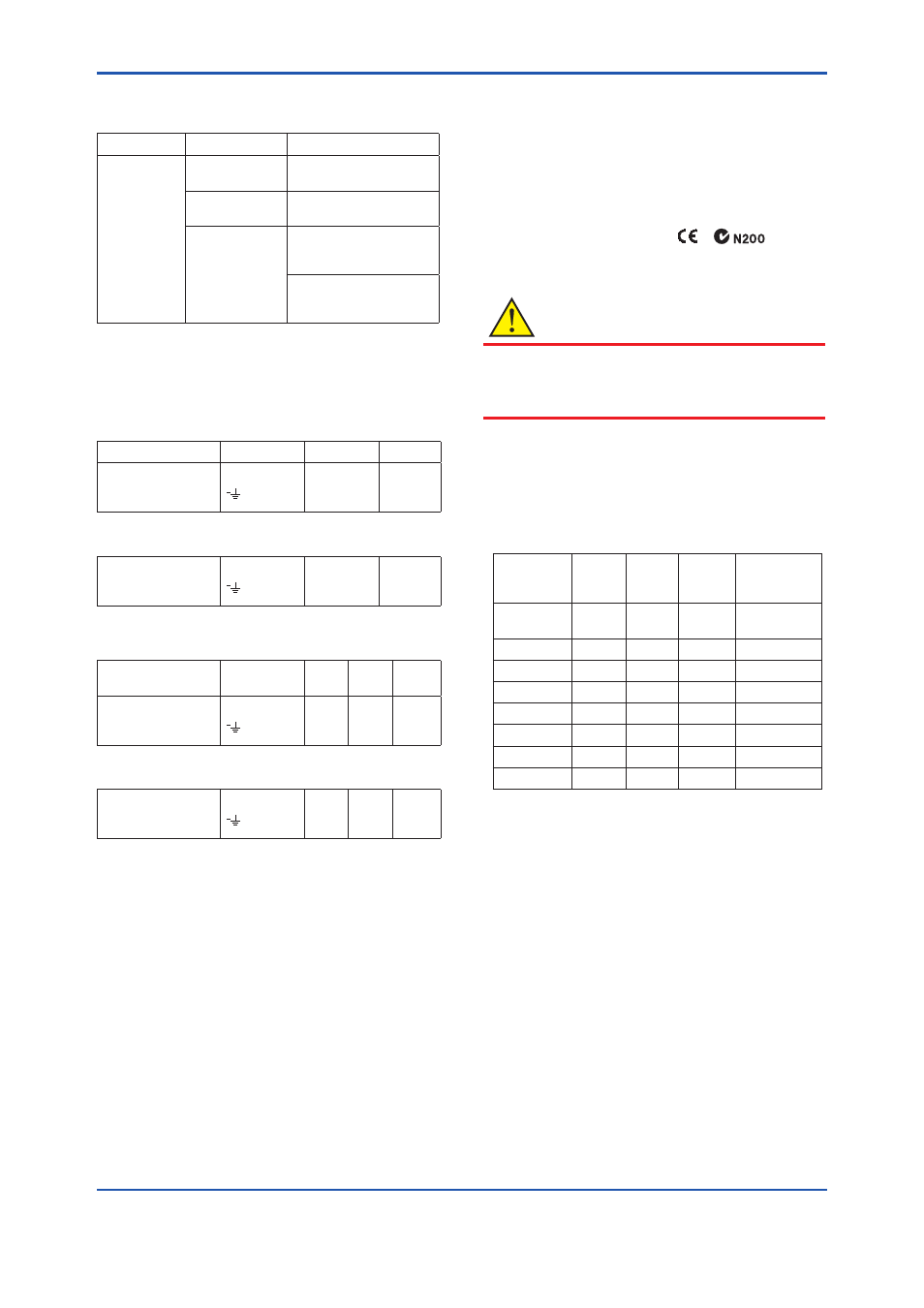

Accuracy for Multi-drop of HART

(generally accepted values)

Vs: Span setting value (m/s)

Size in mm (in.) Span in m/s (ft/s)

Accuracy

25 to 200

(1 to 8)

0.3 ≤ Vs < 1

(1 ≤ Vs < 3.3) ±(0.4+0.3/Vs)% of span

1 ≤ Vs < 2

(3.3 ≤ Vs < 6.7) ± 0.5% of span

2 ≤ Vs ≤ 10

(6.7 ≤ Vs ≤ 33)

± 0.25% of span

(at indications less

than 50% of span)

± 0.5% of rate

(at indications 50% or

more of span)

Repeatability (Reference):

±0.2% of rate

(When the flow velocity is 1.5 m/s toward 2 m/s of

setting span)

Insulation Resistance:

Inspection location

Terminal

Test voltage Standard

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

500 V DC

100 MΩ

or more

When the optional code A is selected (with the lightning protec-

tor), values are as follows.

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO

100 V DC

20 MΩ

or more

Note: Conduct the test according to the instruction manual.

Dielectric Strength:

Inspection location

Terminal

Test

voltage

Test

time

Standard

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO 500 V

AC

1

min.

25 mA

or less

When the optional code A is selected (with the lightning protec-

tor), values are as follows.

Power Supply/Digital

Output - Functional

Grounding

SUPPLY/DO 100 V

AC

1

min.

6 mA

or less

Note: Conduct the test according to the instruction manual.

Safety Requirement Standards:

EN61010-1, CAN/CSA C22.2 No. 61010-1-04

• Altitude of installation site: Max. 2000 m above sea

level

• Installation category: I

“Overvoltage category (Installation category)”

describes a number which defines a transient

overvoltage condition. It implies the regulation for

impulse withstand voltage. “ I ” applies to electrical

equipment which is supplied from the circuit when

appropriate transient overvoltage control means

(interfaces) are provided.

• Pollution degree: 2

“Pollution degree” describes the degree to which

a solid, liquid, or gas which deteriorates dielectric

strength or surface resistivity is adhering. “ 2 ” applies

to normal indoor atmosphere. Normally, only non-

conductive pollution occurs. Occasionally, however,

temporary conductivity caused by condensation must

be expected.

• Indoor/Outdoor use

EMC Conformity Standards:

,

EN61326-1 Class A, Table 2 (For use in industrial

locations)

EN61326-2-3

CAUTION

This instrument is a class A product, and it is de-

signed for use in the industrial environment.

Please use this instrument in the industrial environ-

ment only.

Pressure Equipment Directive:

Module:

H

Type of Equipment: Piping

Type of Fluid:

Liquid and Gas

Group of Fluid:

1 and 2

General-purpose Use/Explosion Proof Type;

MODEL

DN

(mm)

(*1)

PS

(MPa)

(*1)

PS · DN

(MPa ·

mm)

CATEGORY

(*2)

AXR025G/C

25

4

100

Article 3 (*3)

paragraph 3

AXR040G/C

40

4

160

II

AXR050G/C

50

4

200

II

AXR065G/C

65

2

130

II

AXR080G/C

80

2

160

II

AXR100G/C

100

2

200

II

AXR150G

150

2

300

II

AXR200G

200

2

400

III

*1: PS: Maximum allowable pressure for Flowtube

DN: Nominal size

*2: For details, see “Table 6 Covered by ANNEX II of EC

Directive on Pressure Equipment Directive 97/23/EC.”

*3: AXR025G/C is outside the scope of CE marking for PED.

SIL Certification:

AXR series are certified by TÜV in compliance with

the following standards;

IEC 61508: 2000; Part1 to Part7

Functional Safety of Electrical/electronic/programma-

ble electronic safety-related systems; SIL 2 capabil-

ity for single flowmeter use, SIL 3 capability for dual

flowmeter use.