Yokogawa ADMAG AXR User Manual

Page 166

12-14

IM 01E30D01-01EN

<12. OUTLINE>

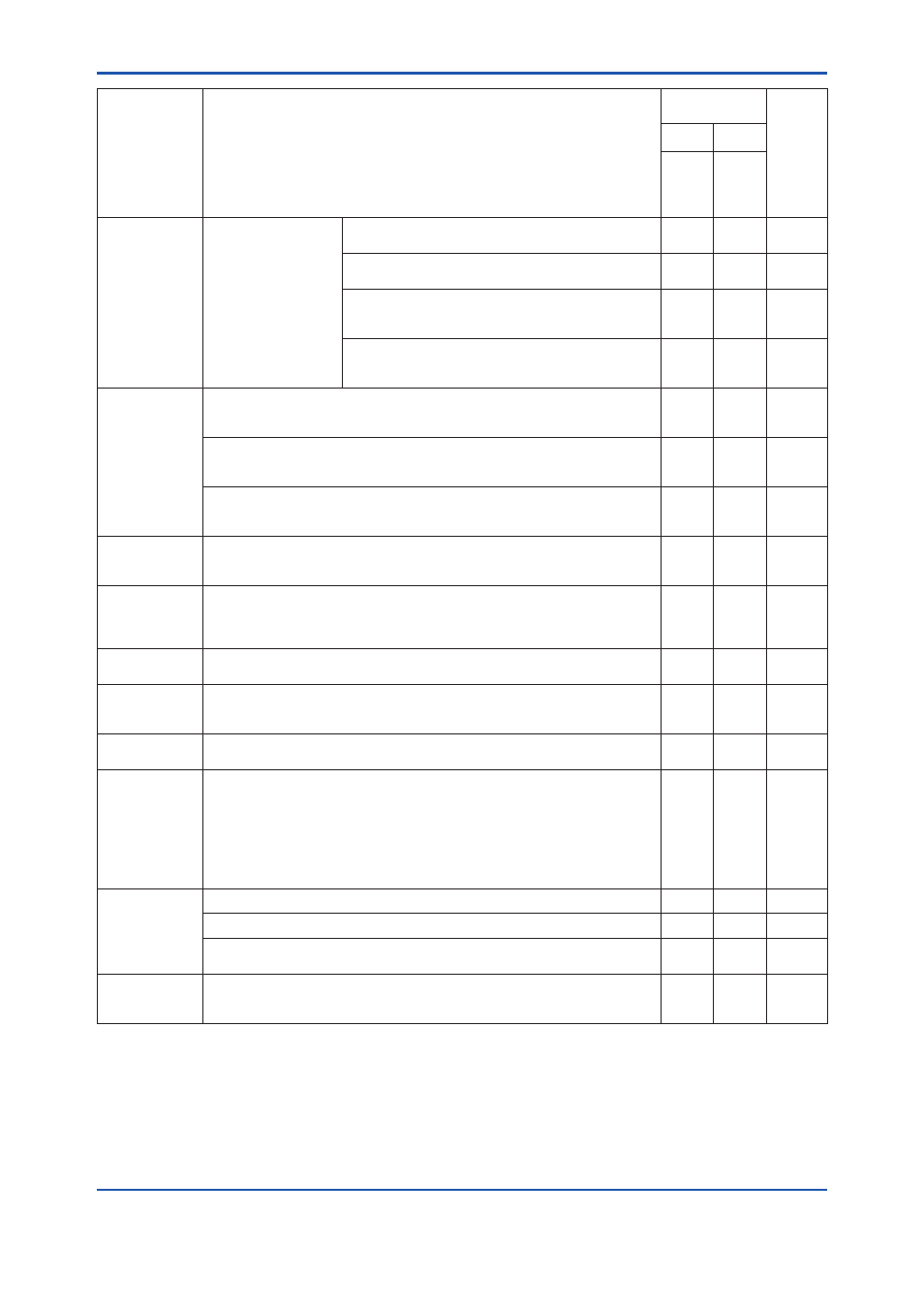

Item

Specifications

Applicable

Model

Code

General

Explosion

proof

A

XR

**

*G

A

XR

**

*C

Bolts, Nuts, and

Gaskets (*2)

Bolts, nuts, and gaskets

are provided for wafer

connections. Available

only for ANSI 150,

JIS10K, or, JIS20K

wafer connections.

Bolts and nuts: Carbon steel;

Gaskets: Chloroprene rubber (*3)

○

○

BCC

Bolts and nuts: Carbon steel;

Gaskets: PTFE-sheathed non-asbestos (*4)

○

○

BCF

Bolts: JIS SUS304 (AISI 304 SS stainless steel equivalent);

Nuts: JIS SUS403 (AISI 403 SS stainless steel equivalent);

Gaskets: Chloroprene rubber (*3)

○

○

BSC

Bolts: JIS SUS304 (AISI 304 SS stainless steel equivalent);

Nuts: JIS SUS403 (AISI 403 SS stainless steel equivalent);

Gaskets: PTFE-sheathed non-asbestos (*4)

○

○

BSF

Special Gaskets

(*5)

Viton® gaskets for use with PVC piping.

Allowable temperature and pressure are equivalent to Valqua #4010, special fluor-

orubber not mixed.

○

○

GA

Acid-resistant Viton® gaskets for use with PVC piping.

Allowable temperature and pressure are equivalent to Valqua #4010, special fluor-

orubber mixed (mixing #D2470).

○

○

GC

Alkali-resistant Viton® gaskets for use with PVC piping.

Allowable temperature and pressure are equivalent to Valqua #4010, special fluor-

orubber mixed (mixing #RCD970).

○

○

GD

Oil-prohibited

Use

Electrodes, linings, and grounding rings are assembled and packed with polyethyl-

ene after being cleaned with water and acetone and dried with air.

The label ‘OIL FREE’ is affixed.

○

○

K1

Oil-prohibited

Use with

Dehydrating

Treatment

Electrodes, linings, and grounding rings are assembled and packed with polyethyl-

ene including desiccants after being cleaned with water and acetone and dried with

air.

The label ‘OIL & WATER FREE’ is affixed.

○

○

K5

Epoxy Resin

Coating

Epoxy resin coating which has alkali-resistance instead of standard polyurethane

resin coating. The color is same as standard type.

○

○

X1

High Anti-corro-

sion Coating

Three-layer coating (polyurethane coating on two-layer epoxy resin coating) in the

same range as that for the standard coating. The color is same as standard type.

Salt/alkali/acid/weather-resistance.

○

○

X2

Material

Certificate

Reproduced material certificates for pipe, electrodes, grounding rings/grounding

electrodes, flanges or mini flanges.

○

○

M01

Hydrostatic Test

The test verifies the absence of leaks by applying the following water pressures

(which are determined under process connection conditions) to linings for ten min-

utes. Test results are described in the Note column of a test certificate (QIC).

Process Connection:

Water Pressure:

ANSI Class 150, DIN PN10, JIS 10K 1.5 MPa

ANSI Class 300, DIN PN16, JIS 20K 3.0 MPa

DIN PN40

6.0 MPa

JIS F12

1.25 MPa

○

○

T01

Calibration Cer-

tificate

Level 2: The Declaration and the Calibration Equipment List are issued.

○

○

L2

Level 3: The Declaration and the Primary Standard List are issued.

○

○

L3

Level 4: The Declaration and the Yokogawa Measuring Instruments Control System

are issued.

○

○

L4

Vent Hole

With a vent hole provided for permeable fluids (such as nitric acid, hydrofluoric acid,

or sodium hydroxide at high temperature).

Available only for a flange type tube.

○

○

H