Model and suffix code, Model and suffix code -9, Nmodel and suffix code – Yokogawa ADMAG AXR User Manual

Page 161: Wafer type

12-9

IM 01E30D01-01EN

<12. OUTLINE>

n

MODEL AND SUFFIX CODE

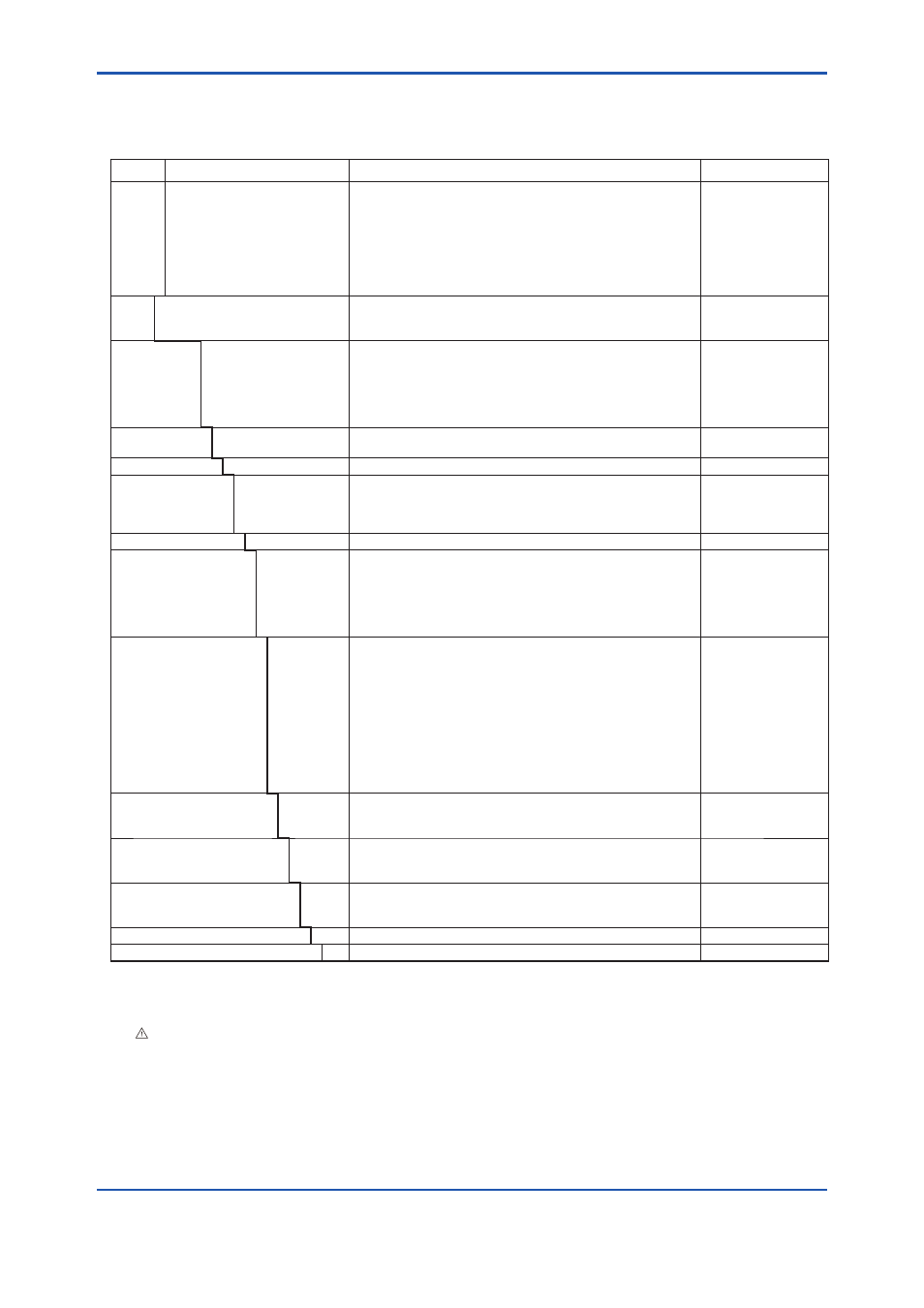

● Wafer Type

Model

Suffix Code

Description

Applicable Model

AXR025

AXR040

AXR050

AXR065

AXR080

AXR100

AXR150

AXR200

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

Size 25 mm (1 in.)

Size 40 mm (1.5 in.)

Size 50 mm (2 in.)

Size 65 mm (2.5 in.)

Size 80 mm (3 in.)

Size 100 mm (4 in.)

Size 150 mm (6 in.)

Size 200 mm (8 in.)

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Two-wire Magnetic Flowmeter Integral Flowmeter

Use

G -------------------------------------------------

C -------------------------------------------------

General-Purpose Use

Explosion proof Type (*1)

Size 25 mm (1.0 in.) to

100 mm (4.0 in.)

Output Signal

and

Communication

-D -----------------------------------

-E -----------------------------------

-J -----------------------------------

Integral Flowmeter with 4 to 20 mA DC Output and digital

communication (BRAIN protocol)

Integral Flowmeter with 4 to 20 mA DC Output and digital

communication (HART protocol) (*12)

Integral Flowmeter with 4 to 20 mA DC Output with digital

communication (HART5/HART7 protocol) (*13)

Power Supply

1 --------------------------------- Integral Flowmeter Operating voltage range 14.7 to 35 V DC

Two-wire system

Lining (*2)

A ------------------------------ Fluorocarbon PFA

Electrode Material (*2)

L ---------------------------

P ---------------------------

H ---------------------------

T ---------------------------

JIS SUS316L (AISI 316L SS/EN 1.4404 Equivalent)

Platinum-iridium

Hastelloy C276 Equivalent

Tantalum

Electrode Structure

1 ------------------------ Non-replaceable

Grounding Ring and

Grounding Electrode

Material (*2)

N --------------------

S --------------------

L --------------------

P --------------------

H --------------------

T --------------------

None (*3)

JIS SUS316 (AISI 316 SS/EN 1.4401 Equivalent)

JIS SUS316L (AISI 316L SS/EN 1.4404 Equivalent)

Platinum-iridium

Hastelloy C276 Equivalent

Tantalum

Process Connection

(*4) (*5)

-AA1 -------------

-AA2 -------------

-AD1 -------------

-AD2 -------------

-AD4 -------------

-AJ1 -------------

-AJ2 -------------

-AG1 -------------

ANSI Class 150

Wafer

ANSI Class 300

Wafer

DIN PN 10

Wafer (*6)

DIN PN 16

Wafer (*6)

DIN PN 40

Wafer (*6)

JIS 10K

Wafer

JIS 20K

Wafer

JIS F12 (JIS75M)

Wafer

Size 200 mm (8.0 in)

Size 65 mm (2.5 in.) to

200 mm (8.0 in.)

Size 25 mm (1.0 in.) to

50 mm (2.0 in.)

Size 80 mm (3.0 in.) to

200 mm (8.0 in.)

Lay Length

1 ---------------

2 ---------------

Lay length code 1 (*7)

Lay length code 2 (*8)

Size 80 mm (3.0 in.) to

200 mm (8.0 in.)

Electrical Connection (*9)

-0 -----------

-2 -----------

-4 -----------

JIS G1/2 female

ANSI 1/2 NPT female

ISO M20 × 1.5 female

Indicator (*10)(*11)

1 ---------

2 ---------

N --------

Integral Flowmeter with indicator (Horizontal)

Integral Flowmeter with indicator (Vertical)

Integral Flowmeter without indicator

Calibration

B ----- Always B

Options

/

Optional code (See the Table of Optional Specifications)

*1: For explosion proof types, specify types of explosion proof certification using the optional codes.

For the TIIS flameproof type, select optional code G11. Available only for JIS G1/2 female electrical connections.

Available only for wiring of using a flameproof packing adapter approved by Yokogawa.

The flameproof metal conduit wiring for TIIS flameproof type is not permitted.

*2: Users must consider the characteristics of selected wetted parts material and influence of process fluids.

The use of inappropriate materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage

to plant facilities. It is also possible that the instrument itself can be damaged and that fragments from the instrument can contami-

nate the user’s process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite,

and high-temperature steam (150°C [302°F] or above). Contact Yokogawa for detailed information of the wetted parts material.

*3: Available only for metal piping.

*4: Mating dimensions are based on standards as follow:

ANSI: ASME B 16.5, DIN: DIN 2501, JIS: JIS B 2220 and JIS G 3443-2