Fluid Components International GF03 User Manual

Page 50

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Model GF03 Flow Meter

4 6

Doc. No. 06EN003352 Rev. B

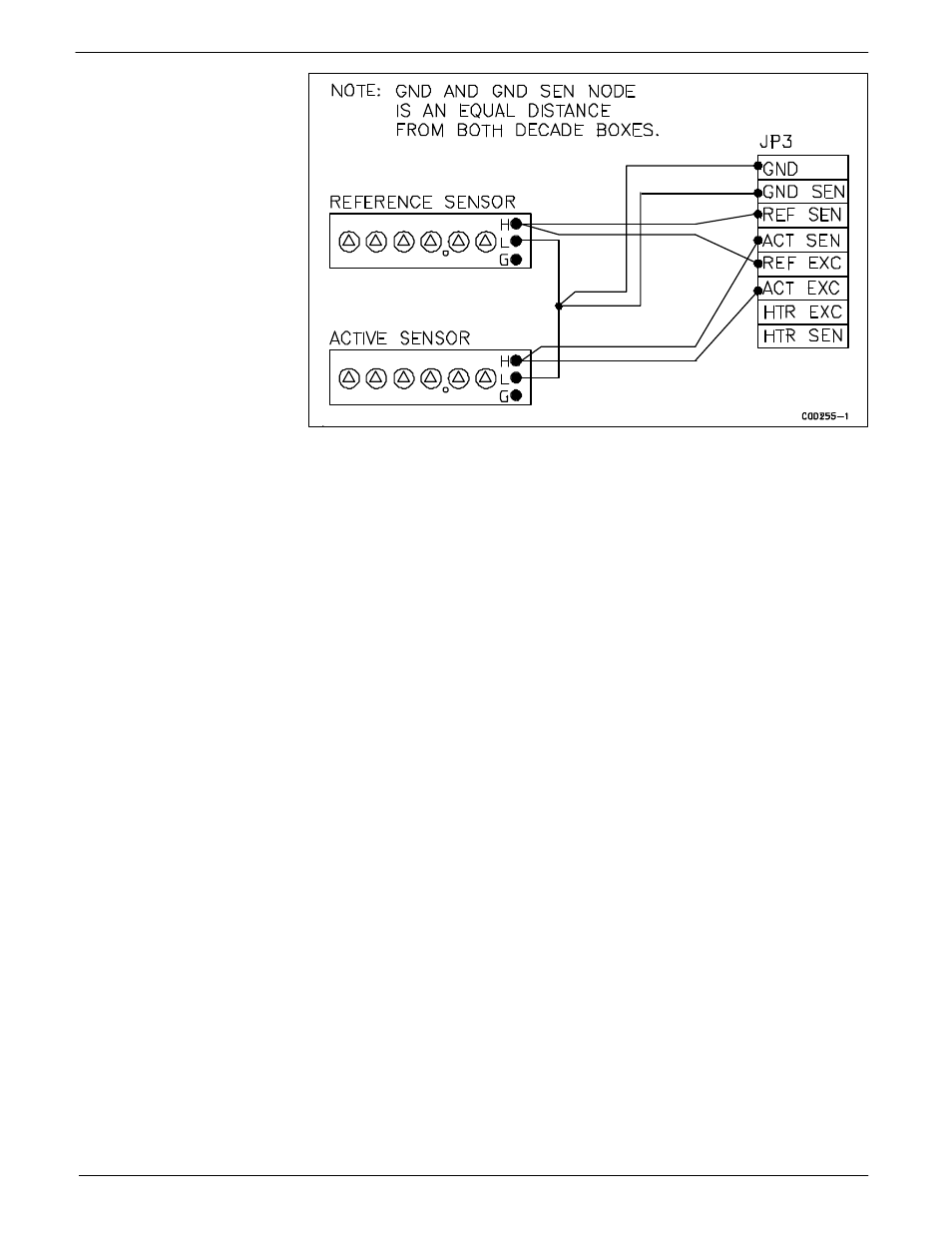

Figure 27 - Decade Box Connections

4.

Set the reference decade box to 1000 ohms, depending on type of nominal flow element

resistance.

5.

Set the active decade to the same reading as step 3, plus the

∆

R value from the

∆

R table

(i.e. 1000 ohms + 25 ohms

= 1025 ohms).

6.

For current loop outputs, connect the milliamp meter between the +I OUT (positive lead)

and OUT COM (negative lead) on connector terminal JP6 and select a range appropriate

for your output current. For the voltage output signals, connect a DMM across the

+E OUT and OUT COM on connector terminal JP6.

7.

Turn power ON and allow the instrument 10 minutes to stabilize.

8.

Be sure the flow transmitter is in the correct group.

9.

Increase the decade resistance connected to the active terminal by the value shown in the

∆

R column for the low-limit signal. Set the active decade for a resistance of 1000 ohm

+ the

∆

R value. The meter reading should equal the recorded value within

±

1% of the

full signal range.

Example:

4-20 milliampere Output Signal = 1% of 16 milliampere = 0.16 milliampere =

Tolerance.

10. Repeat step 7 for the other flow rates in the Delta R Table for this flowmeter.

11. Compare results of the verification measurements with the output signal values recorded

on the Delta R Data Sheet to determine if the transmitter is functioning properly. Also

verify the display reading matches.

12. Turn power OFF and disconnect the decade resistors. Connect the proper wires from the

flow element to terminal block.

13. Disconnect the milliamp meter. Connect the output load to the appropriate OUT+ and

OUT COM terminals on the lower (I/O/P) board.

14. Close the enclosure, making sure that none of the wires are caught. Ensure that all seals

and gaskets are properly installed. If a custom enclosure exists, be sure it is placed back

into safe operating condition.

If the readings are good, the flow transmitter is good and problem may involve the flow

element. If readings are off, a flow element calibration may be required or the flow transmitter

needs to be setup.