Fluid Components International CMF Series Manual Installation of Flow Element User Manual

Fluid Components International Equipment

Installation of sensor

FlexCOR

™

Model CMF Series

22

Fluid Components Intl

Document 06EN003327 Rev. -

4.1

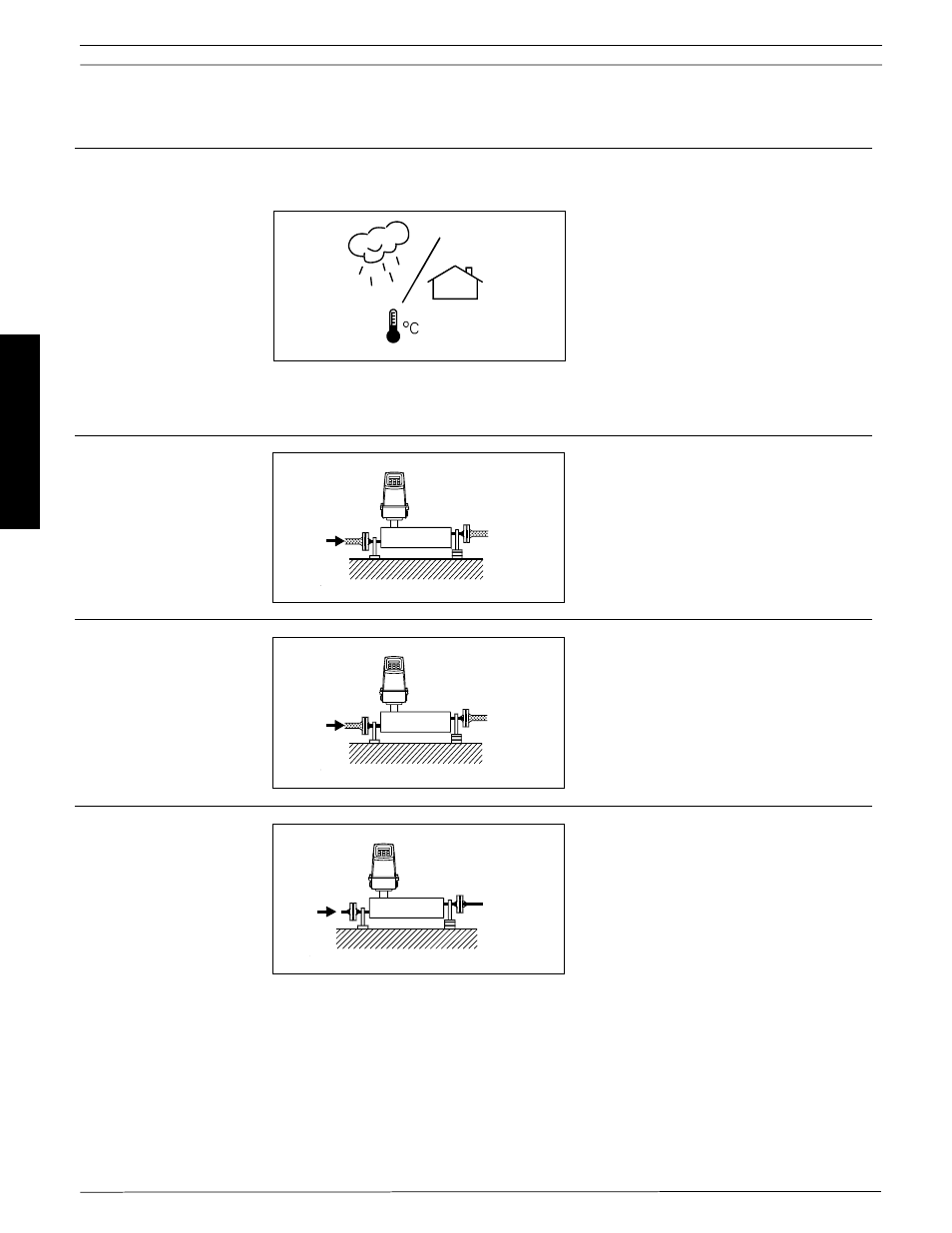

Location

To ensure the optimum function of measuring equipment it is important that the installation

instructions are followed closely, point by point.

The flowmeter can be located both indoors and outdoors, but the following conditions must be

observed:

Liquid temperature: -58 to 356°F (-50 to +180°C).

The grade of enclosure can be choosen from

IP 20 up to IP 67.

When the temperature difference between a

liquid and the surroundings is large, the sen-

sor must be insulated to prevent 2-phase flow

and thereby measuring inaccuracy. This ap-

plies especially in the case of low flow.

Important!

The sensor must always

be completely filled with a homogeneous liquid or gas in single

phase, otherwise measuring errors will occur.

4.2

Cavitation

Avoid cavitation in the system, i.e. sucking in or

releasing air into the system, because this may

produce errors.

Static back pressure minimum 0.1 - 0.2 bar.

4.3

Air bubbles

Avoid large quantities of air collecting in the

sensor because these will disturb measure-

ment. Homogeneous mixtures of air and sol-

ids, however, will not disturb measurement.

When there is air in the liquid, installation of an

air trap ahead of the meter is recommended.

If there is air/gas in the liquid or liquids which

are volatile, horizontal sensor mounting is

recommended.

4.4

Mounting

The unit must be mounted on a flat wall or steel

frame (vibration-free).

4.

Installation of

sensor