General information – Fluid Components International GF03 User Manual

Page 5

Doc. No. 06EN003352 Rev. B

1

Model GF03 Flow Meter

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

1. General Information

This document describes the procedures required to install, operate, maintain, and troubleshoot

the Model GF03 Flowmeter. There are a wide range of possible configurations and information

related to the optional features. The flowmeter is composed of a remote thermal dispersion

sensing transducer (flow element) connected to a microprocessor-based electronics control

and display package (flow transmitter). The flow element is attached to the flow transmitter

thru a cable of up to 1000 feet or 300 meters (remote instrument).

The instrument is designed to operate in gaseous flow metering environments. The flowmeter

is factory calibrated to handle a range of flows.

The primary flow element consists of two thermowells of the same size, shape and mass. One

thermowell contains a platinum RTD and a heater element. The other contains one RTD. The

RTD located with the heater element is called the active RTD. The other RTD is referred to

as the reference RTD. Since the active RTD is embeded in the heater, the temperature of the

active thermowell is always above the temperature of the process media. The temperature at

the reference RTD is the temperature of the process media. When the process media is flowing

past the active RTD a quantity of heat is carried off into the flow stream. The amount of heat

taken from the active RTD is a function of the process media mass flow rate. A

∆

T

(temperature) exists between the two thermowells and a proportional

∆

R (ohms resistance)

exists between the active and the reference RTDs. The

∆

R is measured by the flow transmitter.

The relationship of

∆

R to the calibrated flow rate is calculated by the flow transmitter and is

converted into both analog and digital outputs.

The Gas Compensation element provides a

∆

R value similar to the primary flow element. This

value is a no-flow

∆

R based on the thermo physical properties of the gas mixture minus any

flow component. This value is used to correct gas composition changes in the Transmitter

microprocessor.

Description

Theory of Operation

Sensing Element

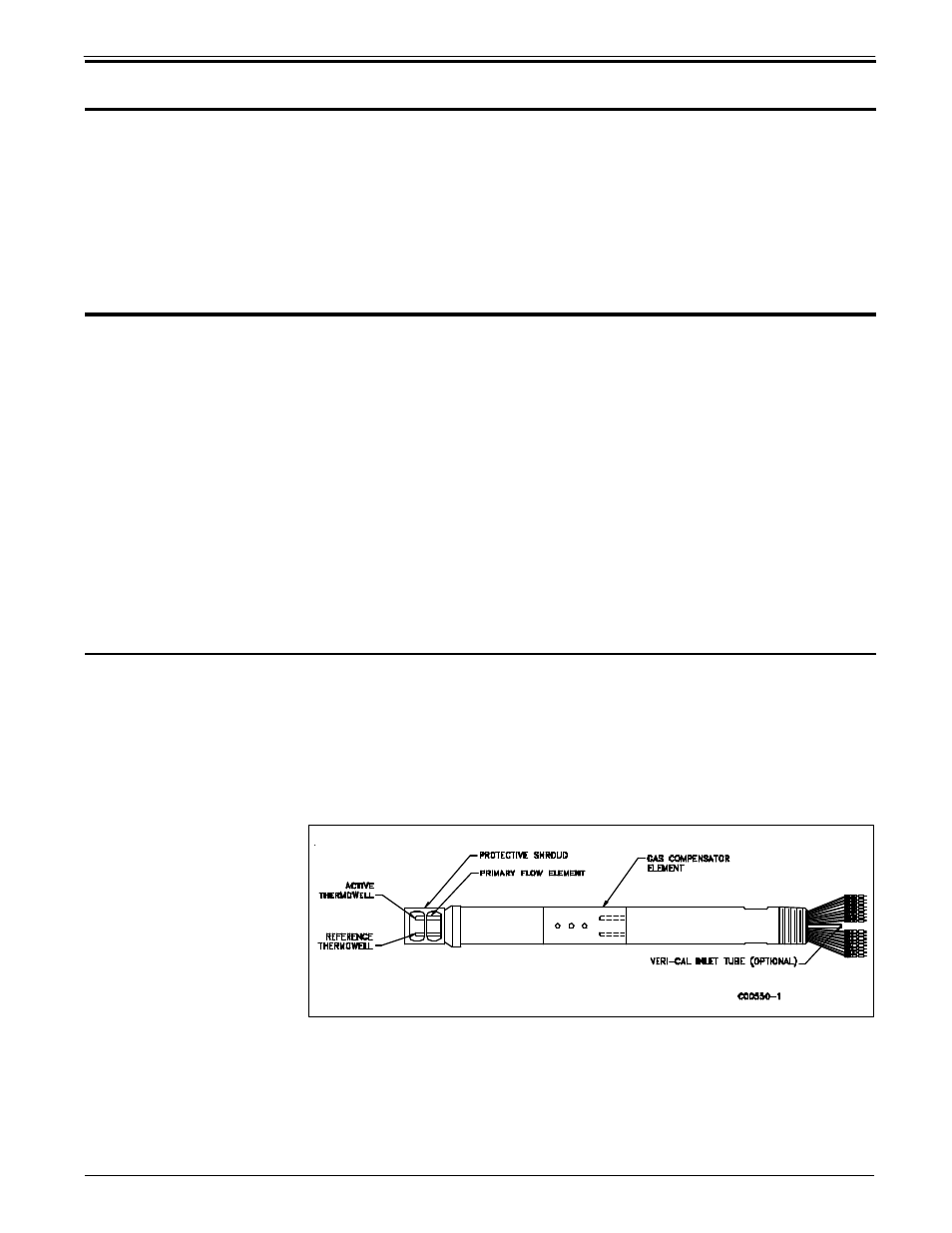

The standard sensing element is an all welded 316L stainless steel insertion probe. The

element consists of the primary flow element located on the end of the probe and the

compensator element located in the insertion pipe. The optional Veri-Cal inlet tube runs

the length of the insertion pipe exiting into the base of the primary flow element. This tube

allows the Veri-Cal system to distribute a repeatable flow rate on the primary flow element

for calibration verification purposes.

Figure 1 - Flow Element