In-depth troubleshooting the flow element – Fluid Components International GF03 User Manual

Page 46

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Model GF03 Flow Meter

4 2

Doc. No. 06EN003352 Rev. B

Check Serial Numbers

Verify that the serial number of the flow element and the flow transmitter are the same. The

flow element and the flow transmitter are a matched set and cannot be operated independently

of each other. The only exception is when the flow transmitter has been specifically

configured to be a replacement.

Check the Resistance of the Flow Element

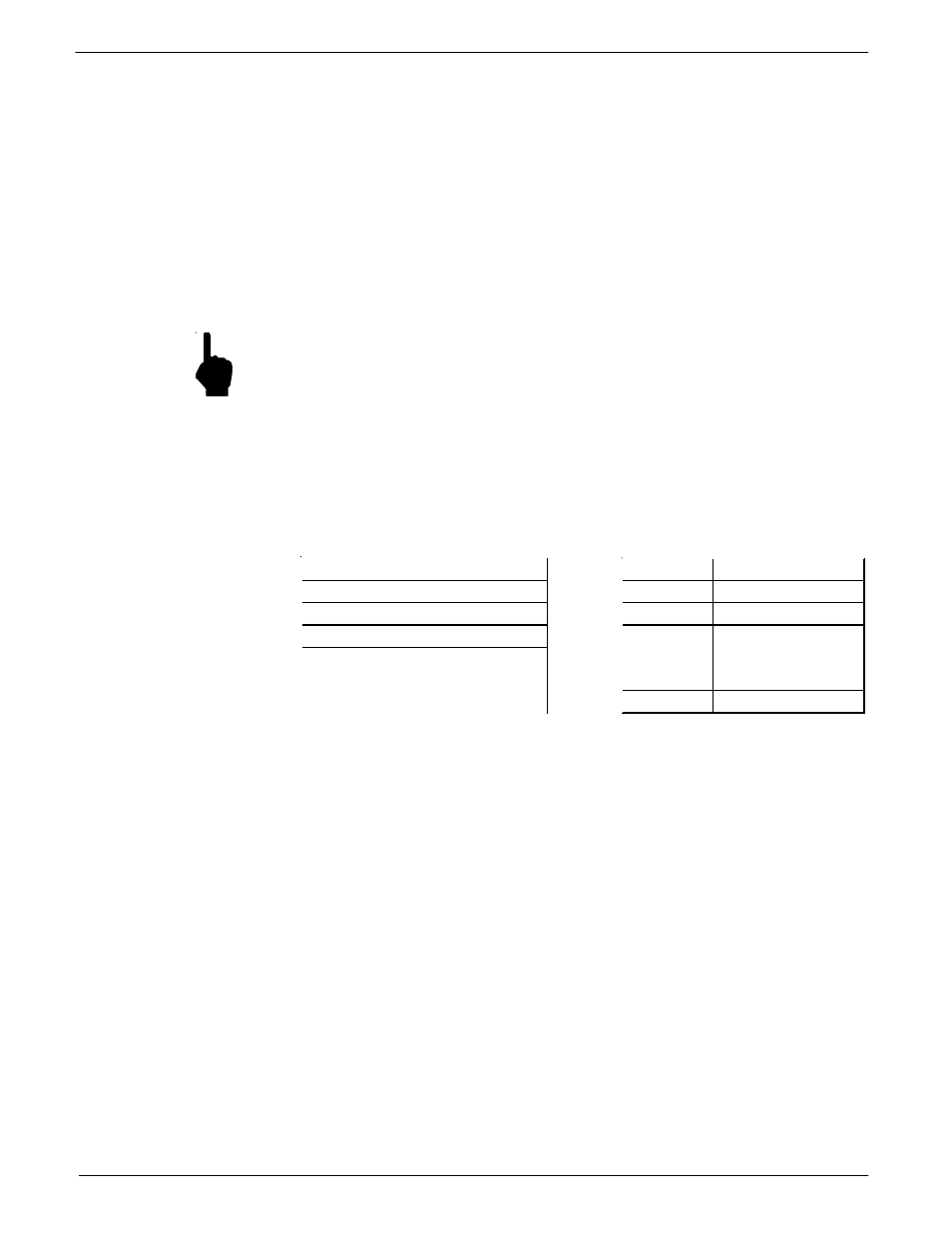

Use Tables 9 and 10 to determine if the flow element is wired incorrectly or has failed. Turn

off the input power to the transmitter. Unplug the flow element at JP3 located on the lower

board and measure resistances described below by touching the DMM test leads to the JP3

terminal screws. (Remember to reconnect JP3 back to the flow transmitter when finished.)

Repeat resistance check on TS2.

NOTE:

If the system does not allow the disconnection of the flowmeter power, or

unplugging the flow element, then proceed to the section, "In-Depth

Troubleshooting - The Flow Transmitter".

All resistances in Tables 9 and 10 are based on a temperature of 32°F (0 °C). Resistances

acrosst the ACT and the REF RTD’s are approximately 1080 ohms* at 70 °F ( 21 °C ). The

resistances will continue to increase for higher temperatures at the flow element. Check

resistance from each pin in the local/remote enclosure to case ground. There should be an

infinite resistance.

In-Depth

Troubleshooting

The Flow Element

Pin Number

Approximate Resistance

1 to 2

0 Ohms

2 to 3

1000 Ohms

2 to 4

1000 Ohms

2 to 5

1000 Ohms

2 to 6

1000 Ohms

2 to 7

115 Ohms

Table 9 - Resistance at JP3

Terminal Plug

Primary Flow Element

Table 10 - Resistance at TS2

Compensator Elemenet

Pin Number

Approximate Resistance

1 to 2

0 Ohms

2 to 3

1000 Ohms

2 to 4

1000 Ohms

3 to 4

2000 Ohms

4 to 6 , 3 to 5

0 Ohms

7 to 8

110 – 118 Ohms

If the measured resistances do not correspond to Tables 9 and 10 then the flow element is

functioning properly. The problem lies else where. Skip the rest of this section and proceed

with the section, In-Depth Troubleshooting - The flow transmitter. If the measured values do

not correspond to Table 5-2 then a problem exists in the flow element. For remote instruments,

with a cable between the flow element and the flow transmitter, the cable could be shorted or

open. To isolate a problem with the cable, check the flow element resistances at the terminal

block located within the flow element (local) enclosure. Disconnect the wires from the

terminal block and measure resistances described below by touching the DMM test leads to

the terminal block screws. The measured resistances should correspond approximately to the

values in Table 5-3.

If the measured resistances correspond to Table 5-3 then the cable or wiring is defective.

Contact customer service for details on how to obtain another cable or flow element.