Dynasonics TFX Ultra Transit Time Flow Meters User Manual

Page 19

Step 2 – Transducer Spacing

The transmitter can be used with five different transducer types: DTTN, DTTL, DTTH, DTTS and DTTC. Meters that utilize

the DTTN, DTTL or DTTH, transducer sets consist of two separate sensors that function as both ultrasonic transmitters and

receivers. DTTS and DTTC transducers integrate both the transmitter and receiver into one assembly that fixes the separation

of the piezoelectric crystals. DTTN, DTTL and DTTH transducers are clamped on the outside of a closed pipe at a specific

distance from each other.

The DTTN, DTTL and DTTH transducers can be mounted in:

• W-Mount where the sound traverses the pipe four times. This mounting method produces the best relative travel

time values but the weakest signal strength.

• V-Mount where the sound traverses the pipe twice. V-Mount is a compromise between travel time and

signal strength.

• Z-Mount where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once.

Z-Mount will yield the best signal strength but the smallest relative travel time.

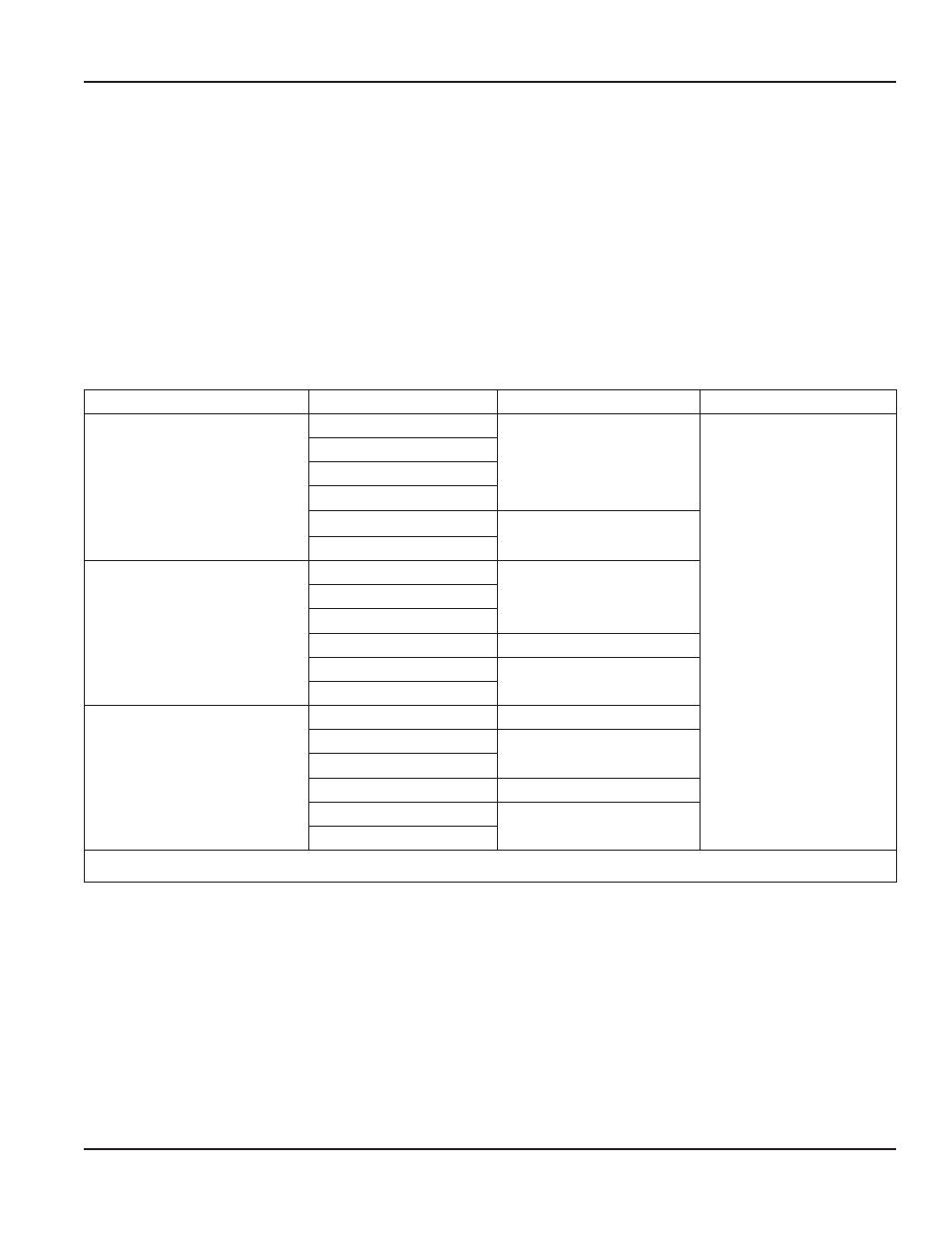

Transducer Mounting Mode

Pipe Material

Pipe Size

Liquid Composition

W-Mount

Plastic (all types)

2…4 in. (50…100 mm)

Low TSS; non-aerated

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Not recommended

Cast Iron

V-Mount

Plastic (all types)

4…12 in. (100…300 mm)

Carbon Steel

Stainless Steel

Copper

4…30 in. (100…750 mm)

Ductile Iron

2…12 in. (50…300 mm)

Cast Iron

Z-Mount

Plastic (all types)

> 30 in. (> 750 mm)

Carbon Steel

> 12 in. (> 300 mm)

Stainless Steel

Copper

> 30 in. (> 750 mm)

Ductile Iron

> 12 in. (> 300 mm)

Cast Iron

TSS = Total Suspended Solids

Table 2: Transducer mounting modes — DTTN, DTTL, and DTTH

For further details, reference

Figure 9

. The appropriate mounting configuration is based on pipe and liquid characteristics.

Selection of the proper transducer mounting method is not entirely predictable and many times is an iterative process.

Table 2

contains recommended mounting configurations for common applications. These recommended configurations may

need to be modified for specific applications if such things as aeration, suspended solids, out of round piping or poor piping

conditions are present. Use of the flow meter diagnostics in determining the optimum transducer mounting is covered later

in this section.

TRANSDUCER INSTALLATION

Page 19

March 2014