Pre-operation inspection – RIDGID Hydraulic Pipe Bender User Manual

Page 9

Hydraulic Pipe Bender

7

• Inspect the power cord and plug for damage or

modification, such as cuts or a missing ground

plug.

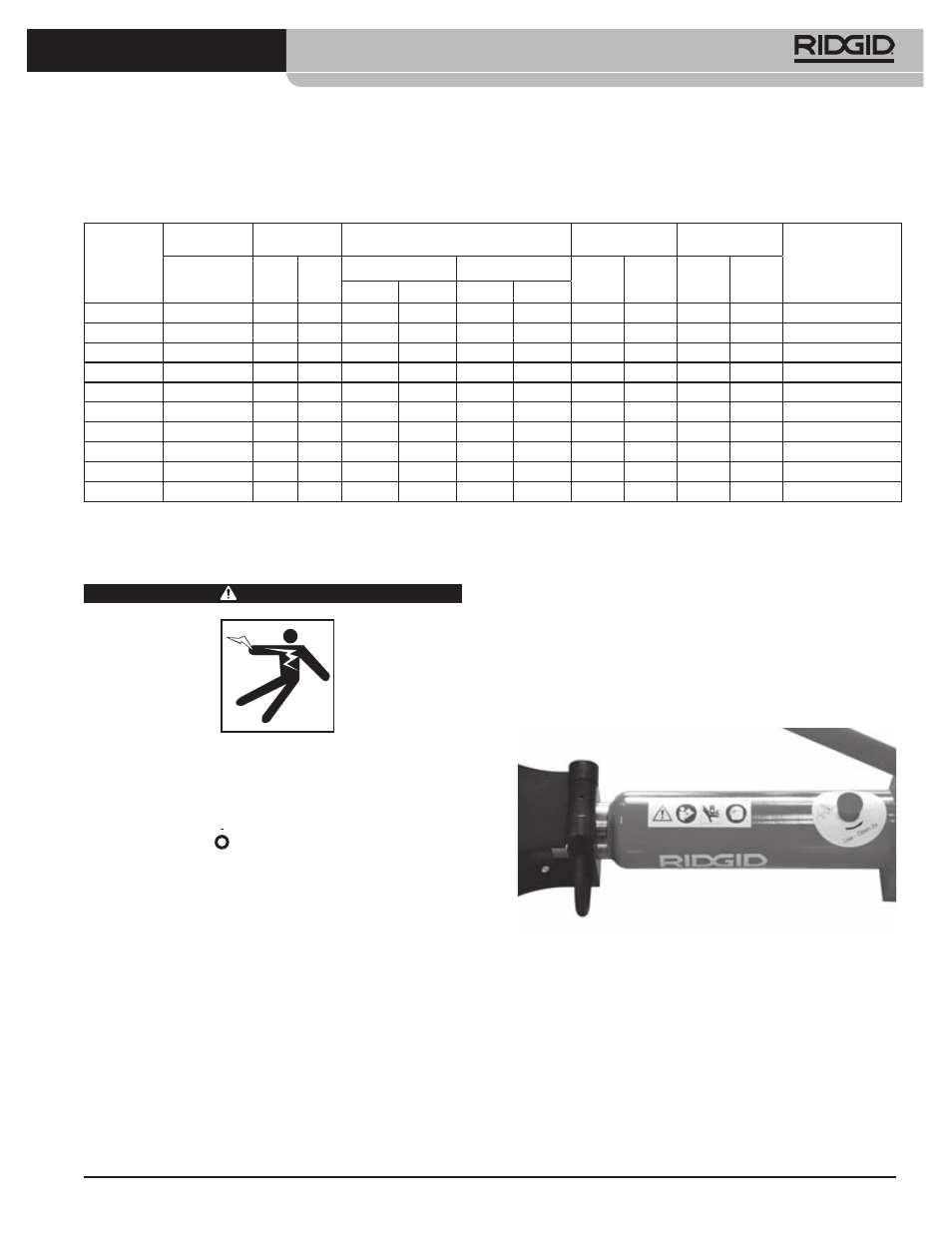

• Presence and legibility of the warning label. See

Figure 4A and 4B.

If any issues are found during the inspection of the

bender, do not use until those issues have been cor-

rected.

Figure 4A – Warning Label (Manual)

Manual

Pre-Operation Inspection

WARNING

Before each use, inspect your pipe bender and cor-

rect any problems to reduce the risk of serious inju-

ry from electric shock, crushing injuries and other

causes and prevent machine damage.

1. If an electric bender, make sure the ON/OFF switch

is in the OFF ( ) position and the power cord is

un plugged.

2. Clean any oil, grease or dirt from the pipe bender,

including the handles and controls. This allows bet-

ter inspection of the pipe bender and helps prevent

the pipe bender or control from slipping from your

grip during use.

3. Inspect the bender for:

• Hydraulic leaks. Check the hydraulic fluid level

and adjust as needed (see Maintenance Section).

• Any broken, cracked, bent, missing, misarranged

or binding parts or any other condition that may

prevent the safe and normal operation of the

bender.

• Cracks or breaks in the formers and corner sup-

ports.

All benders come with appropriate formers and corner supports for the size range, and are packaged in a

reusable wooden crate. Formers are for pipes to EN10255 and equivalent as listed below:

Former

* Bend radius to centerline of pipe. ** See description for more information.

Catalog No.

Nominal Pipe

Size

Pipe O.D.

Wall Thickness

Bend Radius*

Weight

Pipe**

Type/Standard

Inch

Inch

mm

MIN.

MAX.

Inch

mm

lbs

kg

Inch

mm

Inch

mm

37218

1

/

4

"

0.540 13,5

0.08

2,2

0.16

4

2.36

60

2.2

1

EN10255, ASTM A53

37223

3

/

8

"

0.675 17,2

0.09

2,3

0.16

4

1.77

45

1.8

0,8

EN10255, ASTM A53

37228

1

/

2

"

0.840 21,3

0.10

2,6

0.16

4

1.97

50

2.4

1,1

EN10255, ASTM A53

37233

3

/

4

"

1.050 26,9

0.10

2,6

0.16

4

3.15

80

4.0

1,8

EN10255, ASTM A53

37238

1"

1.315 33,7

0.13

3,2

0.20

5

4.33

110

4.0

1,8

EN10255, ASTM A53

37243

1

1

/

4

"

1.660 42,4

0.13

3,2

0.20

5

5.31

135

4.6

2,1

EN10255, ASTM A53

37248

1

1

/

2

"

1.990 48,3

0.13

3,2

0.20

5

6.10

155

9.5

4,3

EN10255, ASTM A53

37253

2"

2.375 60,3

0.14

3,6

0.22

5,5

8.66

220

14.4

6,5

EN10255, ASTM A53

37258

2

1

/

2

"

2.875 76,1

0.14

3,6

0.28

7

12.60

320

38.5

17,5

EN10255, ASTM A53

37263

3"

3.500 88,9

0.16

4

0.30

7,6

15.35

390

59.9

27,2

EN10255, ASTM A53