Hydraulic pipe bender – RIDGID Hydraulic Pipe Bender User Manual

Page 13

Hydraulic Pipe Bender

11

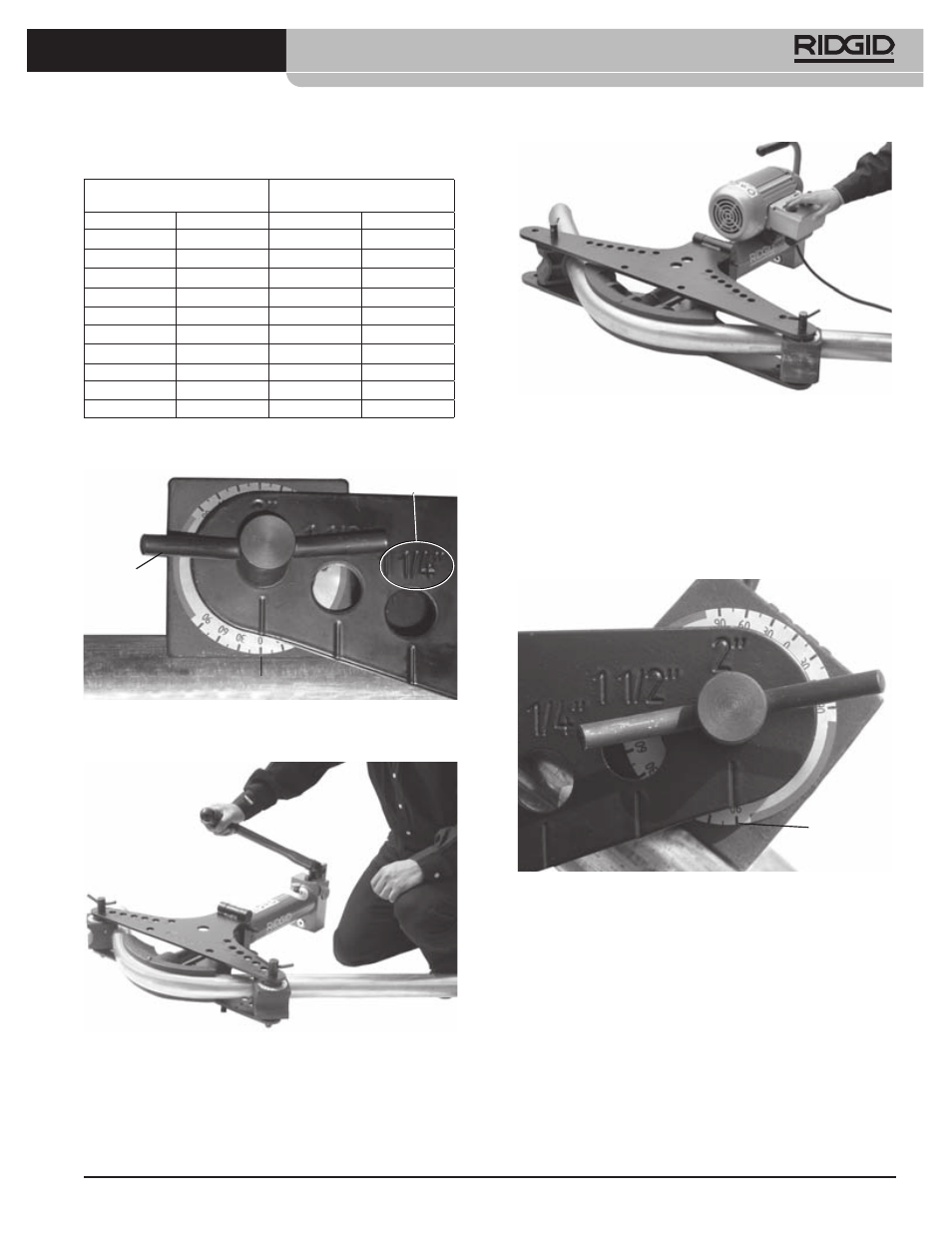

Chart 1 – Minimum Pipe Length Past The Center Of

The Pin

Figure 12 – Angle Indicator Alignment – Start of Bend

Pins Fully

Inserted

In Correct

Position

Pipe Size

Markings

Zero Alignment

Figure 13 – Operating the Manual Bender

Figure 14 – Operating the Electric Bender

3. Continue to advance the ram and bend the pipe.

As the pipe is bent, the ends will move. Stay clear

of the moving pipe. Monitor the angle indicators

(Figure 15). The average of the angles measured by

each angle indicator equals the approximate total

angle bent.

Figure 15 – Angle Indicator – End of Bend

Angle

Indicator

Watch the ram as it extends. If you can see a small

groove in the ram (Figure 16), stop advancing the

ram to prevent hydraulic leaks and ram damage.

4. For certain sizes of pipe (2

1

/

2

”, 3”), a ram extension

must be used to form a 90 degree bend. When the

groove in the ram (Figure 16) is visible, stop ad-

vancing the ram. Make sure that the pipe is prop-

erly supported to prevent it from moving or falling.

Turn the release knob to the retract position, and

retract the ram far enough to allow the extension

to be inserted between the end of the ram and the

former. Insert the extension and carefully advance

Pipe Size O.D.

Min. Distance Center Line of Pin

to End of Pipe

Inch

mm

Inch

mm

1

/

4

13,5

1.6

40

3

/

8

17,2

1.6

40

1

/

2

21,3

1.9

47

3

/

4

26,9

2.0

51

1

33,7

2.1

54

1

1

/

4

42,4

2.3

58

1

1

/

2

48,3

2.5

63

2

60,3

2.2

56

2

1

/

2

76,1

3.3

84

3

88,9

3.7

93