Operating instructions – RIDGID Hydraulic Pipe Bender User Manual

Page 11

Hydraulic Pipe Bender

9

Figure 7 – Assembled 2”/3” Electric Bender

6. Open the fill cap on the cylinder two full turns. This

allows air into the reservoir during use for proper

operation. (See Figure 10.)

Powering the Electric Bender

1. Confirm that the ON/OFF ( / ) switch is in the

OFF ( ) position.

2. Makes sure that the power cord is routed away

from the work area. Run the cord along a clear path

to the outlet, and with dry hand plug in. Keep all

connections dry and off the ground. If the power

cord is not long enough, use an extension cord

that:

• Is in good condition.

• Has a plug similar to that on the tool.

• Is rated for outdoor use and contains a W or W-A

in the cord designation (i.e. SOW), or complies

with H05VV-F, H05RN-F types or IEC type design

(60227 IEC 53, 60245 IEC 57).

• Has sufficient wire size (16 AWG (1,5 mm²) for 50’

(15,2 m) or less, 14 AWG (2,5 mm²) for 50’ – 100’

(15.2 m – 30.5 m) long). Undersized wires can

overheat, melting the insulation or causing a fire

or other damage.

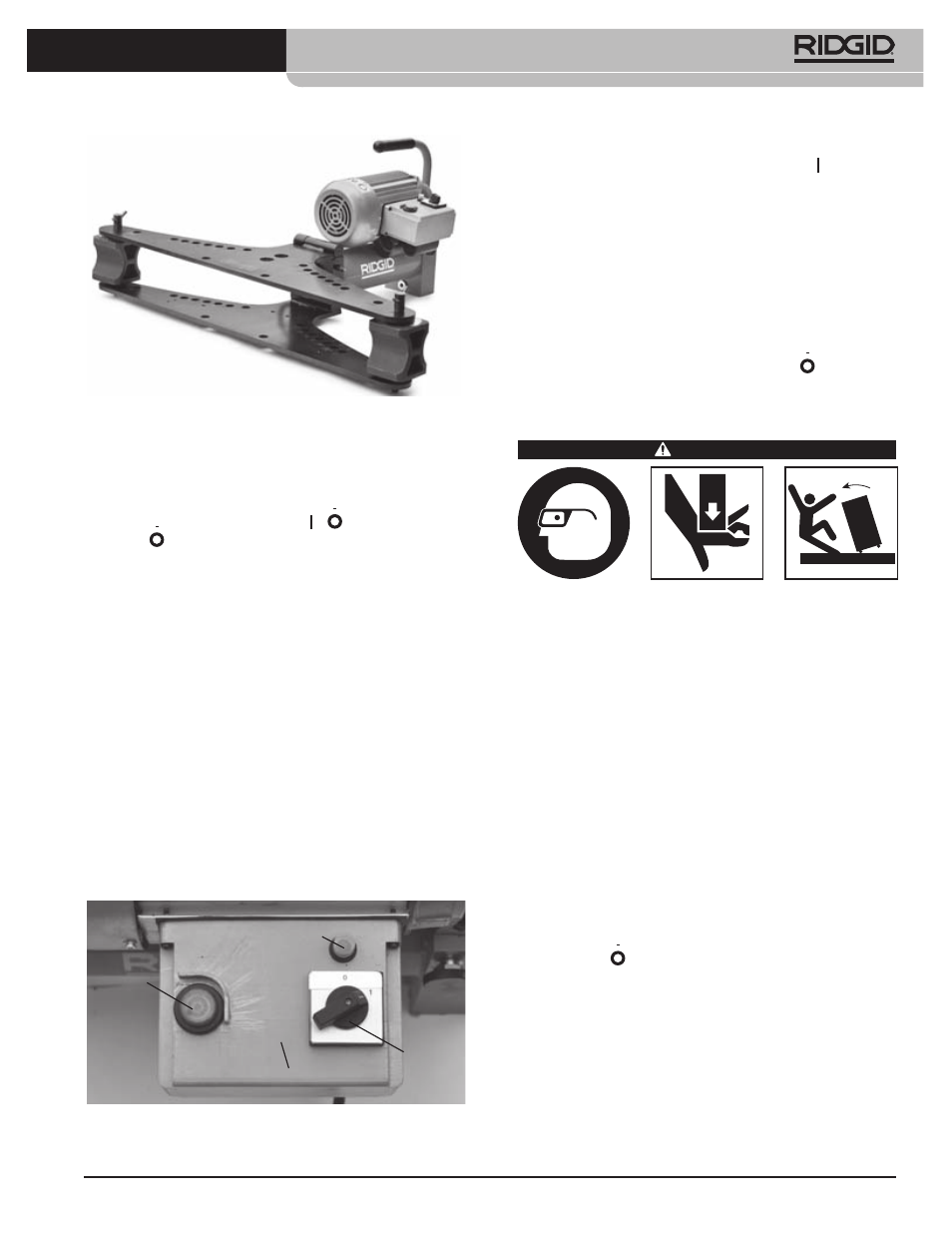

Figure 8 – Electric Bender Controls

Run Switch

Circuit Breaker

Motor

ON/OFF

Switch

3. Check the bender for proper operation.

Move the ON/OFF switch to the ON ( ) position.

Press and release the Run switch. If the ON/OFF

switch and Run switch do not control the motor

operation, do not use the bender until it has been

repaired.

Depress and hold the Run switch. Inspect for mis-

alignment, binding, odd noises or any other unusual

conditions. Release Run switch. If any unusual con-

ditions are found, do not use the machine until it has

been repaired.

Move the ON/OFF switch to the OFF ( ) position.

Operating Instructions

WARNING

Keep your fingers and hands away from the bend-

ing attachments and work piece during bending.

Your fingers, hands and other body parts can be

caught, crushed, fractured or amputated if they

become entangled in the bender or between these

components and any other object.

Properly support the tool and pipe. This will help to

prevent the tipping of the pipe and equipment.

Pipe moves during bending and can cause strik-

ing or crushing injuries. Be sure there is adequate

clearance around the pipe before bending

Follow operating instructions to reduce the risk of

injury from entanglement, striking, crushing, elec-

trical shock and other causes.

Loading the Pipe

1. Confirm that the equipment and work area has

been properly set up and is free of by-standers and

other distractions. Confirm ON/OFF switch is on

the OFF ( ) position.

2. If needed, mark the pipe to be bent at the appro-

priate location.

3. Remove the pins from the corner supports and

open the upper wing.

4. Choose the appropriate bending former for the

pipe to be bent. Formers are marked with the size

and catalog number. See the Specifications for more

information. Place former over the end of the ram.