Dh-10, Single header wire feeder, Double header wire feeder – Lincoln Electric AC-225C User Manual

Page 66: Semiautomatic wire feeders

Semiautomatic Wire Feeders

www.lincolnelectric.com/wire-feeders

LN

™

-10

The LN

™

-10 semiautomatic wire feeder features the revolutionary split wire guide which

precisely aligns and supports the wire through the entire feeding system. The system

also features a rugged 4 driven roll design for positive wire feeding. The LN

™

-10’s

modular design provides for many mounting options, including boom mounting.

Single Header Wire Feeder

• Standard dual procedure allows operator to set

different voltage and wire feed speeds and

switch between the two.

• Selectable trigger control for standard 2-step,

interlocking 4-step, spot weld and cold feed

trigger control.

• Digital Display standard.

• Preflow/Postflow/Burnback and Spot Timer

standard.

• Three-year warranty on parts and labor.

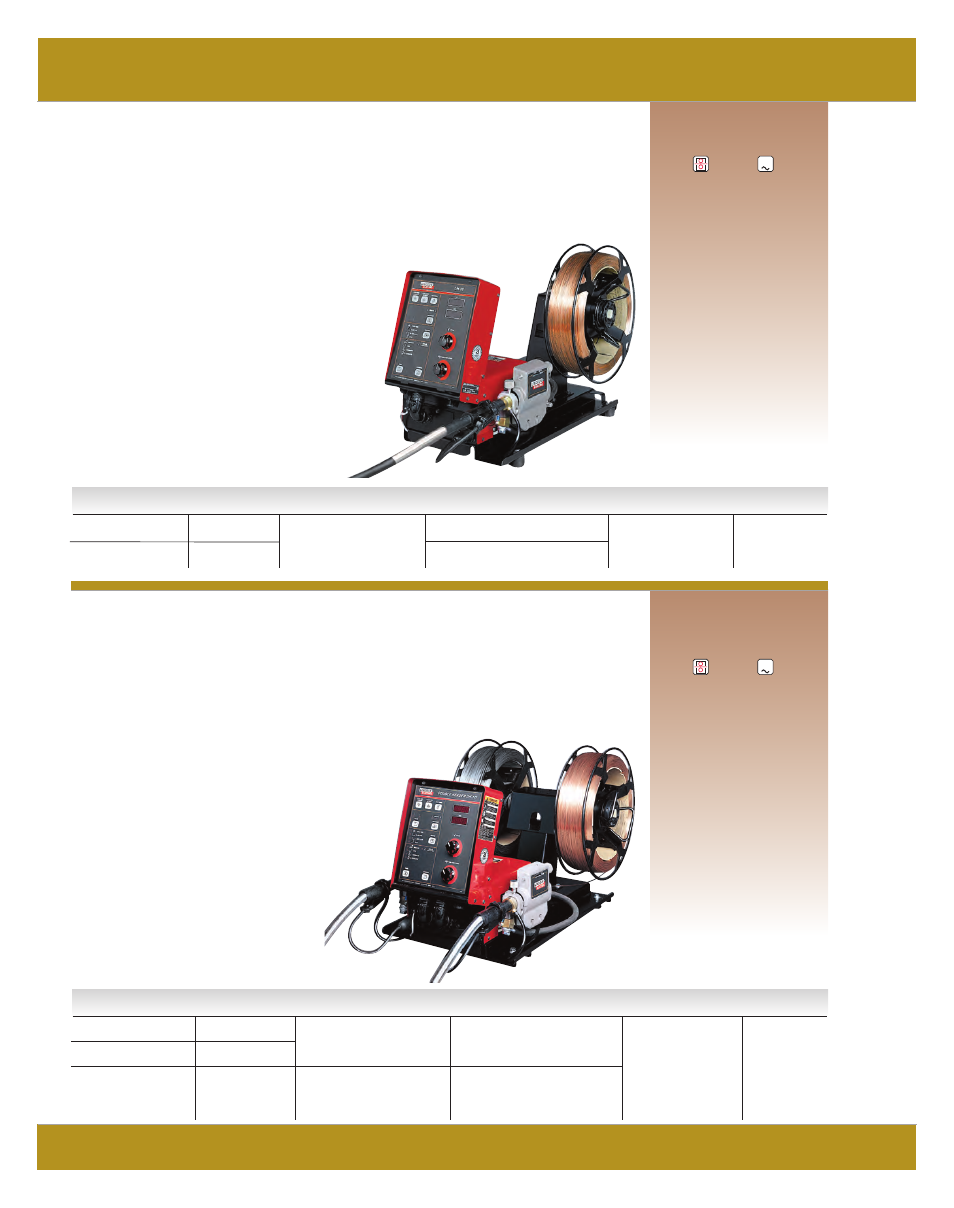

DH-10

Precision times two! This DH-10 dual wire feeder utilizes Lincoln’s

®

revolutionary split wire guide

system to precisely align and feed wire, and its dual wire feeder system allows you to weld with

two different wires, with two different welding procedures using one power source.

Double Header Wire Feeder

Processes

• MIG

• Flux-Cored

• Submerged Arc

Output Input

Bench Model (Std./Std. Speed)

Includes

• Control Cable, 10 ft. (3.0 m)

Required Options

• Drive Roll Kit

• Weld Power Cable

Key Options

• K1501-10 Control Cable

• K1798 Terminal Strip Adapter

Cable

• K1785-12 Control Cable

(Heavy Duty), 12 ft. (3.6 m)

• K1785-16 Control Cable

(Heavy Duty), 16 ft. (4.8 m)

• Fume Extraction System

•

More options at end of section

Literature

E8.200

Processes

• MIG

• Flux-Cored

Output Input

Bench Model (Standard Speed)

Includes

• Control Cable, 10 ft. (3.0 m)

Required Options

• Drive Roll Kit

• Weld Power Cable

Key Options

• K1501-10 Control Cable

• K1798 Terminal Strip Adapter

Cable

• K1785-12 Control Cable

(Heavy Duty), 12 ft. (3.6 m)

• K1785-16 Control Cable

(Heavy Duty), 16 ft. (4.8 m)

•

More options at end of section

Literature

E8.200

Product

Product

Wire Feed Speed Range

Wire Size Range

H x W x D

Net Weight

Name

Number

ipm (m/min)

in (mm)

in. (mm)

lbs.(kg)

LN

™

-10 Bench Model

K1559-3

Low Gear:

Solid: .023-5/64 (0.6-2.4)

16 x 15 x 31

65

(Standard Speed)

35-750 (0.8-19.0)

Cored: .035-1/8 (0.9-3.2)

(406 x 381 x 787)

(29.5)

LN

™

-10

K1564-4

High Gear:

Solid: .023-1/16 (0.6-1.6)

Generic Boom Package

50-750 (1.3-19.0)

Cored: .035-5/64 (0.9-2.0)

Product

Product

Wire Feed Speed Range

Wire Size Range

H x W x D

Net Weight

Name

Number

ipm (m/min)

in. (mm)

in. (mm)

lbs.(kg)

DH-10

K1499-3

35-750

Solid: .023-3/32 (0.6-2.4)

21 x 20 x 32

98

(0.8-19.0)

Cored: .030-1/8 (0.8-3.2)

(521 x 502 x 800)

(44.4)

DH-10

K1521-7

Generic Boom Package

DH-10

K1499-4

Std: 35-750

Solid: .023-3/32 (0.6-2.4)

(Std./High Speed)

(0.8-19.0)

Cored: .030-1/8 (0.8-3.2)

High: 55-1250

Solid: .023-1/16 (0.6-1.6)

(1.3-31.7)

Cored: .035-5/64 (0.9-2.4)

42

VAC

42

VAC

• Each side of the DH-10 wire drive system is driven by its

own motor and gear box for confidence that the feeder

won’t go down.

• Split wire guide and 4 driven rolls for positive wire feeding.

• Presettable voltage and wire feed speed for extra control.

• Standard dual procedure allows operator to set

different voltage and wire feed speeds and switch

between the two.

• Selectable trigger control for standard 2-step,

interlocking 4-step, spot weld and cold feed

trigger control.

• Digital Display standard.

• Preflow/Postflow/Burnback

&

Spot Timer

standard.

• Three-year warranty on parts and labor.

68