Stick electrode, con’t, Consumables, Steel – carbon & low alloy, con’t – Lincoln Electric AC-225C User Manual

Page 102

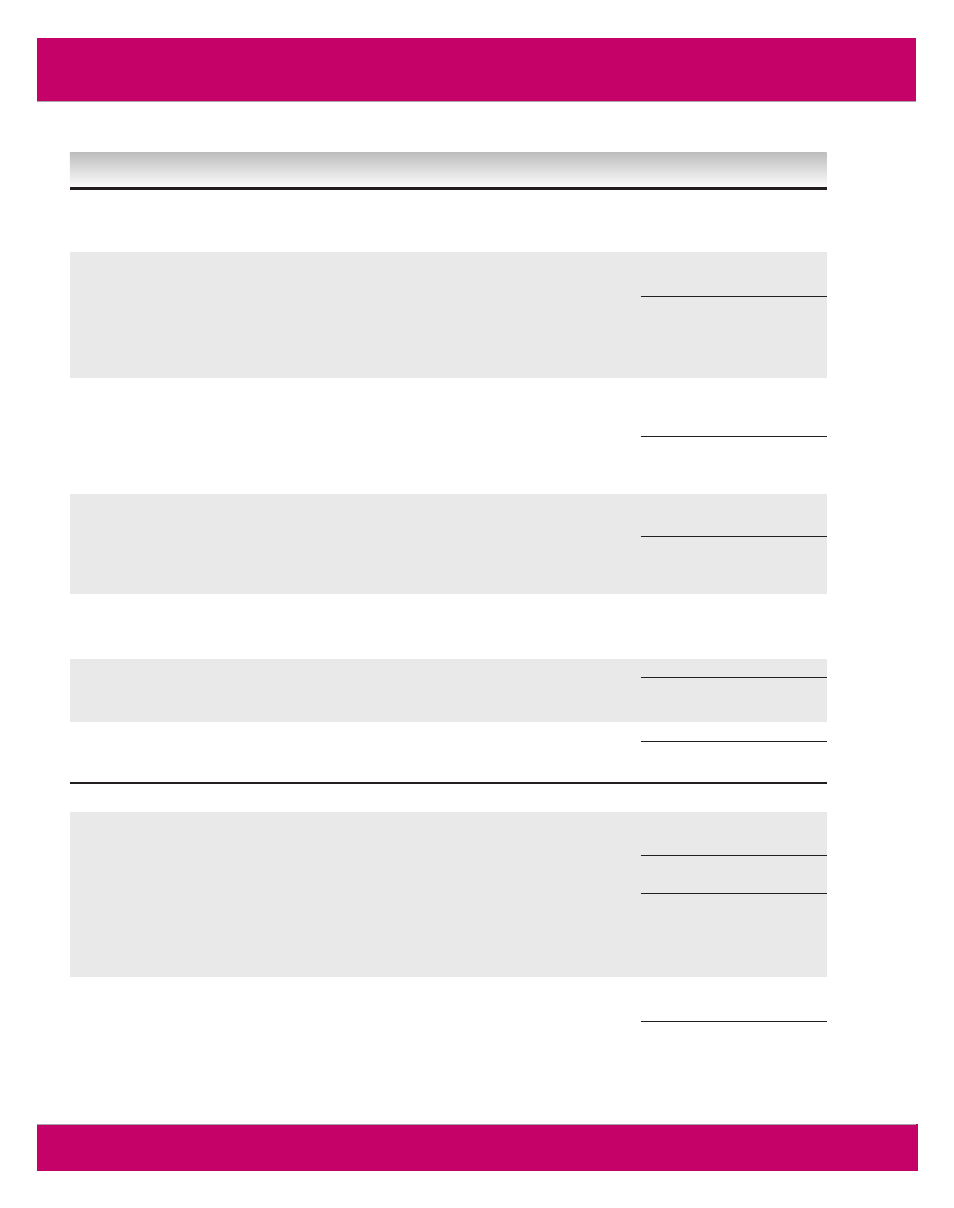

Electrode

AWS

Recm’d

General

Name

Class

Polarity

Description

Steel – Carbon & Low Alloy, con’t.

Low Hydrogen, Low Alloy Steel Stick Electrodes, con’t.

Excalibur

®

E8018-C3 H4R

DC+

Excalibur

®

8018-C3 MR is a 1% nickel all position electrode for fabrication or

8018-C3 MR

AC

repair of 1% nickel steels, as well as a wide variety of other low alloy and

carbon steels.

Excalibur

®

E9018-M H4R

DC+

Excalibur

®

9018M MR is intended for welding high strength steels of 90,000 psi

9018M MR

(620 MPa) tensile strength and higher.

Excalibur

®

E11018M-H4R

DC+

Excalibur

®

11018M MR

™

is designed primarily for joining high strength steel types

11018M MR

™

in the as-welded or stress relieved conditions with excellent low temperature

impact properties and robust welding procedures. All-position welding, except

verticle down.

Jetweld

®

E8018-B2 H4R

DC+

LH-90 MR was designed to meet the rigorous demands of high temperature,

LH-90 MR

E9018-G H4R

AC

high pressure piping assignments. This electrode offers a nominal 1-1/4%

chromium, 1/2% molybdenum deposit and meets the requirements of high tensile

(90,000 psi) steels.

Jet-LH

®

E8018-B2 H4R*

DC+

If your welding involves 1-1/4% chromium and 1/2% moly pipe, tubes, boilers or

8018-B2 MR

AC

castings, you’ll want Jet-LH

®

8018-B2 MR as your welding electrode. It offers a

1-1/4% chromium and 1/2% molybdenum deposit. Reach for this electrode when

(*3/32: E8018-B2 H4)

operating temperatures exceed 850°F (450°C).

Jet-LH

®

E9018-B3 H4R*

DC+

Great low hydrogen stick electrode. For welding 2-1/4% chromium and 1%

9018-B3 MR

AC

molybdenum steels when heat treating is required. Good mechanical properties

in the as-welded and stress relieved condition. Jet-LH

®

9018-B3 MR is a great

(*3/32: E9018-B3 H4)

choice when temperatures exceed 850°F (450°C).

Fill Freeze, Out-Of-Position Pipe Welding, Mild Steel & Low Alloy Steel Stick Electrodes

Fleetweld

®

5P

E6010

DC+

Fleetweld

®

5P is a great choice for welding on dirty, rusty, greasy or painted

steel – especially in vertical or overhead applications.

Fleetweld

®

5P+

E6010

DC+

Lincoln’s

®

Fleetweld

®

5P+ is ideal for steel that’s less than clean. It’s a first choice

for pipe welding, and vertical-up and overhead plate welding. This electrode is

a longtime favorite among operators who handle cross-country and in-plant pipe

welding.

Diameter

Package

Product

inches

Weight Lbs.

Number

3/32

30CT(10EO)

ED032599

1/8

30CT(10EO)

ED032600

5/32

60CT(10EO)

ED032601

3/32

50EO

ED030892

1/8

50EO

ED030893

E5/32

50EO

ED030894

3/16

50EO

ED030895

7/32

50EO

ED030897

1/4

50EO

ED030896

3/32

30CT(10EO)

ED032602

1/8

30CT(10EO)

ED032603

5/32

30CT(10EO)

ED032604

3/16

30CT(10EO)

ED032605

3/32

50EO

ED030868

1/8

50EO

ED030869

5/32

50EO

ED030870

3/16

50EO

ED030871

3/32

30CT(10EO)

ED032606

1/8

30CT(10EO)

ED032607

5/32

30CT(10EO)

ED032608

3/32

50EO

ED031975

1/8

50EO

ED031976

5/32

50EO

ED031977

3/16

50EO

ED031978

1/8

50EO

ED015436

5/32

50EO

ED015426

3/32

25EO

ED023472

1/8

50EO

ED023473

5/32

50EO

ED023474

3/32

25EO

ED023475

1/8

50EO

ED023476

5/32

50EO

ED023477

3/32

40CT(5CT)

ED030141

1/8

40CT(5CT)

ED030142

5/32

40CT(5CT)

ED030143

3/32

30CT(10EO)

ED032561

1/8

30CT(10EO)

ED032562

5/32

30CT(10EO)

ED032563

3/32

50EO

ED010211

1/8

50EO

ED010203

5/32

50EO

ED010216

3/16

50EO

ED010207

7/32

50EO

ED010219

1/4

50EO

ED010200

3/32

30CT(10EO)

ED032564

1/8

30CT(10EO)

ED032565

5/32

30CT(10EO)

ED032566

3/32

50EO

ED010283

1/8

50EO

ED010278

5/32

50EO

ED010285

F3/16

50EO

ED010281

Stick Electrode, con’t.

Package Code Key:

CT = Cardboard Carton EO = Easy Open Hermetic Can TB = Tube

Consumables

www.lincolnelectric.com/welding-consumables

104