Innershield, Self-shielded flux-cored wires, Consumables – Lincoln Electric AC-225C User Manual

Page 119: High speed single pass welding wires

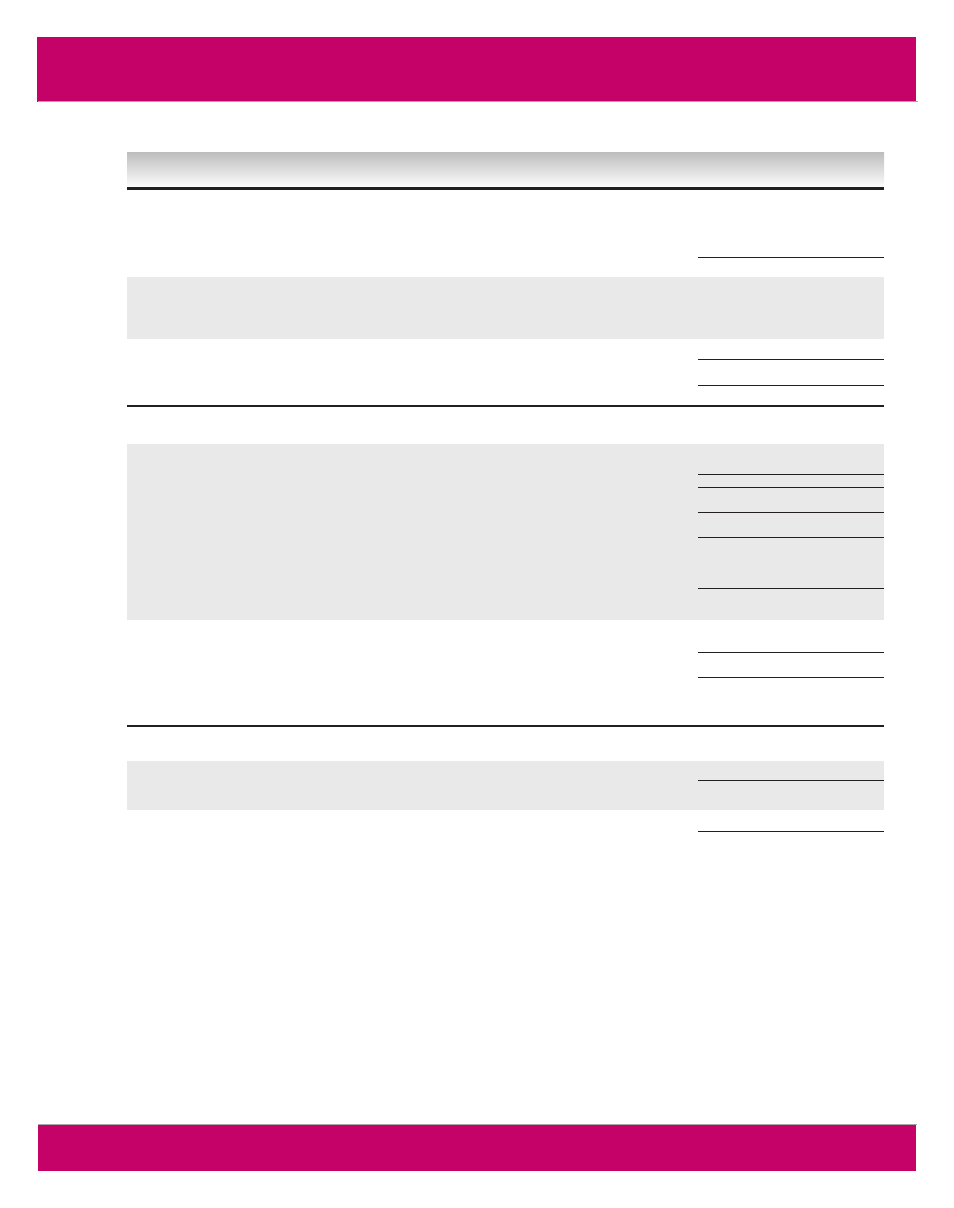

Electrode

AWS

General

Name

Class

Description

High Speed Single Pass Welding Wires

Innershield

®

E70T-3

NR-5 is great for high speed, flat and horizontal, single pass only, automatic welding

NR

®

-5

applications. Recommended for maximum steel thickness up to 3/16” (4.8 mm).

Innershield

®

E70T-10

High deposition rates and fast travel speeds. For automatic and semiautomatic high speed,

NR

®

-131

single pass welding only, on material thicknesses of .110” (2.8 mm) or more. A solid per-

former for twin arc welding applications, especially in flat, horizontal, and automatic

roundabout positions.

Innershield

®

E71T-14

Designed for high speed, single pass only, automatic and semiautomatic welding of carbon

NR

®

-152

steels from .030-3/16” (0.8-4.8 mm) thicknesses. A good choice for galvanized, specialty

zinc-coated or carbon steels.

Out-of-Position Welding Wires with No Impact Requirements

Innershield

®

E71T-11

One of our most popular all-purpose Innershield

®

wires. Versatile wire suitable for all-position

NR

®

-211-MP

welding of light gauge steel or thin plate. Maximum plate thickness for diameters up to .045”

(1.1 mm) is 5/16” (7.9 mm). 1/2” (12.7 mm) for all larger diameters. Low spatter and excellent

weld appearance. Ideal for many applications and an easy wire for operator training.

Innershield

®

E71TG-G

An alternative to NR

®

-211-MP when welding plate thickness up to 3/4” (19.0 mm). A good

NR

®

-212

choice for general purpose, all-position welding. Produces smooth welds with excellent

appearance.

Out-of-Position Welding Wires with Impact Requirements

Innershield

®

E71T-8J

Designed for general welding where excellent Charpy V-Notch impact properties are required.

NR

®

-203MP

Handles poor fit-up on heavy wall tubes and gaps up to 3/8” (9.5 mm) with 1/4” (6.4 mm)

offset.

Innershield

®

E71T8-Ni1

Use for all-position, including vertical down when impact properties and a nickel bearing

NR

®

-203

weld is desired. For single and multiple pass welding on mild steel and some low alloy

Nickel (1%)

steels. Performs well in automatic and semiautomatic applications.

Diameter

Package

Product

inches

Weight Lbs.

Number

3/32

600R

ED012701

.120

600R

ED012698

3/32

600D

ED012699

3/32

600R

ED012163

.045

25SP

EDS01702

.062

50C

ED012185

.068

50C

ED012186

.062

500D

ED024301

.030

5CT(1SP)

ED031448

.035

10CT(1SP)

ED027641

.035

10SP

ED016354

.045

10SP

ED016363

.068

56CT(14C)

ED012506

5/64

56CT(14C)

ED012508

.035

25SSP

ED030637

.045

25SSP

ED030638

.068

25SSP

ED030641

5/64

25SSP

ED030645

.068

50C

ED012507

5/64

50C

ED012509

3/32

50C

ED013869

.045

10SP

ED026090

.068

56CT(14C)

ED027803

5/64

56CT(14C)

ED027794

.045

25SSP

ED030639

.068

25SSP

ED030642

5/64

25SSP

ED030646

5/64

50C

ED026858

5/64

56CT(14C)

ED021604

.068

25SSP

ED030640

5/64

56CT(14C)

ED012385

5/64

50C

ED012386

Innershield

®

Self-Shielded Flux-Cored Wires

Package Code Key:

C = Coil CT = Cardboard Carton D = Speed Feed

®

Drum (wire) or Steel Drum (flux) HS = Hermetically Sealed Pail

R = Speed Feed

®

Reel SP = Plastic Spool SSP = Steel Spool VFB = Vacuum Sealed Foil Bag

Consumables

www.lincolnelectric.com/welding-consumables

121