Submerged arc, Consumables, Lincolnweld – Lincoln Electric AC-225C User Manual

Page 141: Carbon steel cored wire, Lincolnweld low alloy steel cored wires, Carbon steel electrodes (chemistry), Low alloy electrodes (chemistry)

Consumables

www.lincolnelectric.com/welding-consumables

Submerged Arc

143

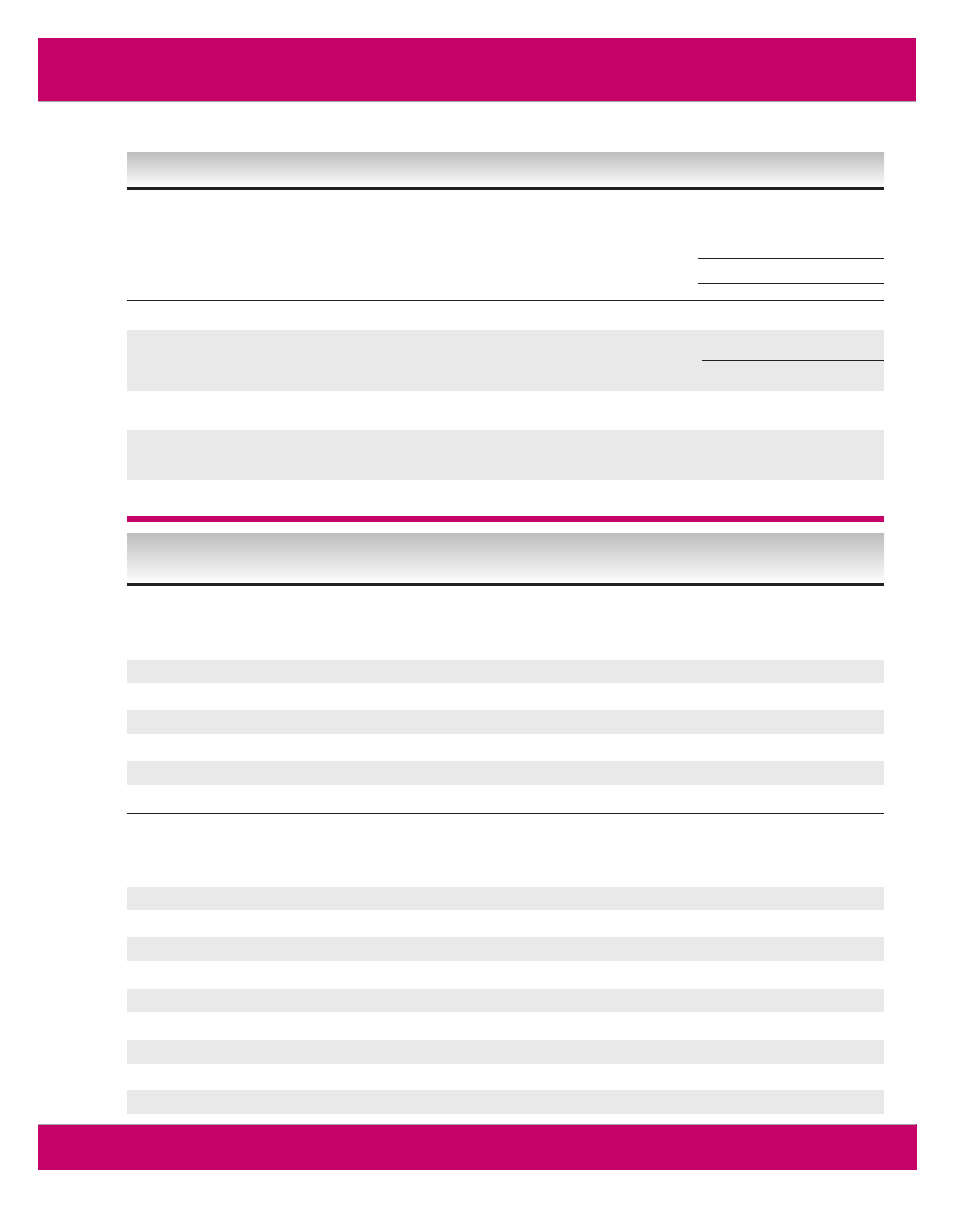

Electrode

AWS

General

Name

Class

Description

Lincolnweld

®

Carbon Steel Cored Wire

Lincolnweld

®

LC-72

EC1

Lincolnweld

®

LC-72 is a cored wire designed to be welded with 980 flux to provide increased

deposition rate over solid wire yet maintain good bead shape, penetration, and slag removal.

Deposition can be increased 10-30% over solid wire.

Lincolnweld Low Alloy Steel Cored Wires

Lincolnweld

®

LAC-B2 ECB2

Here is a subarc wire that’s flux-cored and a great choice for welding chrome-moly steels.

Lincolnweld

®

LAC-B2 is designed to weld with either single or tandem arcs using a neutral

flux.

Lincolnweld

®

LAC-M2 ECM2

Get yield strengths around 100 ksi using this flux-cored wire and the submerged arc process.

Lincolnweld

®

LAC-M2 also delivers V-notch impacts of 15 ft-lbs @ -50° F.

Lincolnweld

®

LAC-Ni2 ECNi2

Lincolnweld

®

LAC-Ni2 is a flux-cored wire designed for the submerged arc process. It’s perfect

for welding weathering steels and all other steels requiring tensile strengths of 70 ksi with

low temperature impacts.

Diameter

Package

Product

in

Weight Lbs.

Number

5/64

50C

ED011099

3/32

50C

ED011098

3/32

300R

EDS01186

3/32

600R

EDS01188

3/32

600D

EDS01187

3/32

60C

ED010954

5/32

60C

ED010955

3/32

600D

ED019581

5/32

600D

ED019582

3/32

50C

ED010981

5/32

50C

ED010982

3/32

50C

ED010986

Package Code Key:

C = Coil D = Speed Feed

®

Drum (wire) or Steel Drum (flux) R = Speed-Feed

®

Reel

AWS Wire Composition Limits

(1)

AWS

ASME

Wire

Class

%C

%Mn

%Si

%Cr

%Ni

%Mo

%Ti

%Zr

%Al

%V

%S

%B

%P

%Cu

Lincolnweld

®

Carbon Steel Electrodes (Chemistry)

Lincoln

®

Electrode Classifications per AWS A5.17-97

L-50

EM13K

.06-.16

.90-1.40

.35-.75

—

—

—

—

—

—

—

.030

—

.030

.35

L-56

EH11K

.06-.15

1.40-1.85

.80-1.15

—

—

—

—

—

—

—

.030

—

.030

.35

L-60

EL12

.04-.14

.25-.60

.10

—

—

—

—

—

—

—

.030

—

.030

.35

L-61

EM12K

.05-.15

.80-1.25

.10-.35

—

—

—

—

—

—

—

.030

—

.030

.35

LA-71

EM14K

.06-.19

.90-1.40

.35-.75

—

—

—

.03-.17

—

—

—

.025

—

.025

.35

LC-72

(2,3)

EC1

.15

1.80

.90

—

—

—

—

—

—

—

.035

—

.035

.35

L-S3

EH12K

.06-.15

1.50-2.0

.25-.65

—

—

—

—

—

—

—

.025

—

.025

.35

Lincolnweld

®

Low Alloy Electrodes (Chemistry)

Lincoln

®

Electrode Classifications per AWS A5.23-97

L-70

EA1

.05-.15

.65-1.00

.20

—

—

.45-.65

—

—

—

—

.025

—

.025

.35

LA-75

ENi1K

.12

.80-1.40

.40-.80

—

.75-1.25

—

—

—

—

—

.020

—

.020

.35

LA-81

(4)

EA2TiB

.05

1.2

.2

—

—

.5

.1

—

—

—

—

.01

—

.20

LA-82

EF2

.10-.18

1.70-2.40

.2

—

.40-.80

.40-.65

—

—

—

—

.025

—

.025

.35

LA-84

EF3

.10-.18

1.75-2.20

.15-.25

—

.80-1.0

.45-.60

—

—

—

—

.010-.020

—

.010-.020 .05-.15

LA-85

ENi5

.12

1.20-1.60

.05-.30

—

.75-1.25

.10-.30

—

—

—

—

.020

—

.020

.35

LA-90

EA3K

.05-.15

1.60-2.10

.50-.80

—

—

.40-.60

—

—

—

—

.025

—

.025

.35

LA-92

EB2R

.07-.15

.45-1.00

.05-.30

1.00-1.75

—

.45-.65

—

—

—

—

.025

—

.025

.35

LA-93

EB3R

.05-.15

.40-.80

.05-.30

2.25-3.00

—

.90-1.10

—

—

—

—

.025

—

.025

.35

LA-100

EM2

.10

1.25-1.80

.20-.60

.30

1.40-2.10

.25-.55

.10

.10

.10

.05

.015

—

.010

.25