Invertec, V350-pro, V450-pro – Lincoln Electric AC-225C User Manual

Page 28: Designed smart. built tough, Multi-process welders, The invertec

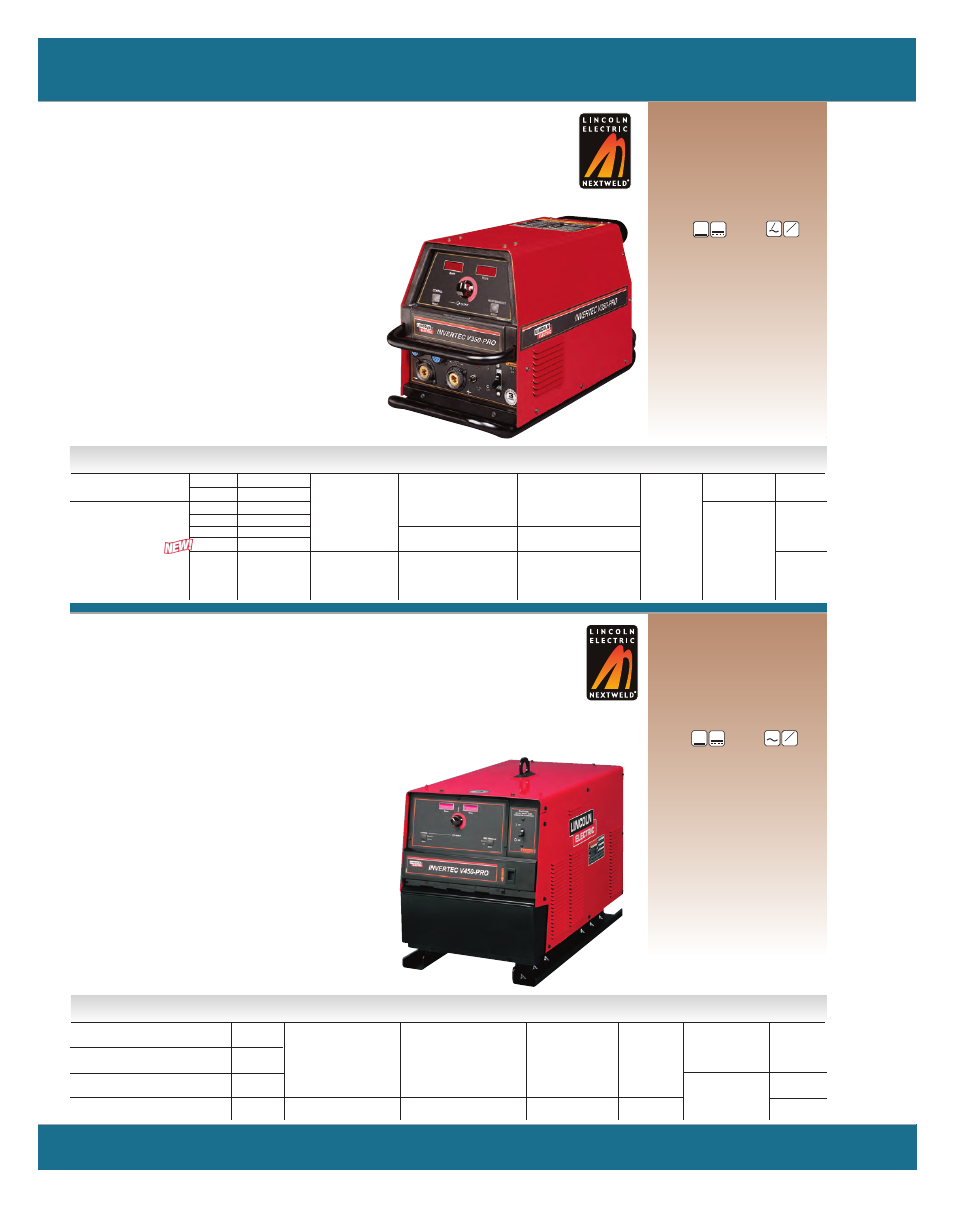

Invertec

®

V350-PRO

The Invertec

®

V350-PRO is a versatile, multi-purpose, multi-process power source

that’s lightweight and portable. Available in construction, factory,

advanced process and factory rack models.

Designed Smart. Built Tough.

Multi-Process Welders

www.lincolnelectric.com/multi-process-welders

DC

1 3

PHASE

60

50

Hz

CV

CC

Product

Product

Input Power

Rated Output

Input Current @

H x W x D

Net Weight

Name

Number

Model

Voltage/Phase/Hertz Current /Voltage/Duty Cycle

Rated Output

Output Range

inches (mm)

lbs.(kg)

Invertec

®

V350-PRO/LF-72

K2437-1

Factory

200-208/230/380-415/

350A/34V/60%

3-ph: 50/42/28-26/23/18

5-425A

55.2 x 28.5 x 55.5

370

Ready-Pak

®

Pkg.

K2438-1

Advanced Process

460/575/3/50/60

1-ph: 94/85/54/42/37

Max OCV:

(1403 x 724 x 1410)

(168)

Invertec

®

V350-PRO

K1728-5

Construction

208/230/415/

80V DC

14.8 x 13.3 x 27.9

81

K1728-6

Factory

460/575/1/50/60

(376 x 338 x 709)

(36.7)

K1728-7

Advanced Process

300A/32V/100%

3-ph: 41-39/36/23-22/19/16

K1728-13

Factory (Tweco

®

)

1-ph: 76/69/41/36/31

K1728-8

CE

200-220/380-400/

350A/34V/60% (3ph)

3ph: 48/28-27/26-24

86.5

415-440/1/3/50/60

320A/33V/60% (1ph)

3ph: 41-37/28-22/22-21

(37.4)

300A/32V/100% (3ph)

275A/31V/100% (1ph)

Processes

• Stick

• TIG

• MIG

• Pulsed (Advanced Process

Panel only)

• Flux-Cored

• Gouging

Output Input

Ready-Pak

®

Package (K2437-1)

Includes

• V350-PRO Factory Model

(K1728-6)

• LF-72 Heavy Duty Wire Feeder

(K2327-3)

• Work

&

Wire Feeder 2/0 Welding

Cable Package, 10 ft. (3.0 m)

• Harris

®

Flowmeter/Regulator

w/Adapter and Hose, 10 ft. (3.0 m)

• Inverter and Wire Feeder Cart

Literature

E5.91

Invertec

®

V450-PRO

Substantial Output. Smart Performance. Rugged Reliability.

Product

Product

Input Power

Rated Output

Input Current @

H x W x D

Net Weight

Name

Number

Voltage/Phase/Hertz

Current /Voltage/Duty Cycle

Rated Output

Output Range

inches (mm)

lbs.(kg)

Invertec

®

V450-PRO/LF-72

K2494-1

208/230/460/575/3/50/60

60Hz: 450A/38V/100%

60Hz: 58/53/25/22A

5-570A

47.5 x 24 x 38

405

Ready-Pak

®

Pkg.

(570A/43V/60%)

(82/78/37/31A)

(1207 x 610 x 965)

(184)

Invertec

®

V450-PRO/LF-74

K2495-1

50Hz: 400A/36V/100%

50Hz: 49/45/23/18A

Ready-Pak

®

Pkg.

(500A/40V/60%)

(67/61/31/25A)

Invertec

®

K2420-1

26.1 x 19.9 x 32.9

293

V450-PRO

(663 x 505 x 835)

(133)

Invertec

®

K2421-1

380/415/3/50/60

400A/36V/100%

36/33A

5-500A

278

V450-PRO (CE)

(500A/40V/60%)

(48/44A)

(126)

The V450-PRO is targeted for shops commonly welding with .052" or larger diameter

wires that also require plenty of power for arc gouging repair work with a 3/8" carbon.

Processes

• Stick

• TIG

• MIG

• Pulsed (Advanced Process

Panel only)

• Flux-Cored

• Gouging

Output Input

Ready-Pak

®

Package (K2494-1)

Includes

• V450-PRO

• LF-72 Heavy Duty Bench Model

Wire Feeder (K2327-3)

• Magnum

®

400 Gun and Cable

Assembly, 15 ft.

• .035-.045" (0.8-1.1 mm) Drive Rolls

and Wire Guides

• Work

&

Wire Feeder 2/0 Welding

Cable Package, 10 ft. (3.0 m)

• Harris

®

Flowmeter/Regulator

w/Adapter and Hose, 10 ft. (3.0 m)

Literature

E5.94

• Features full remote and multi-process capability—

Stick, Touch Start TIG

®

, MIG, flux-cored and arc gouging.

• 5-570 amp output range for all recommended processes.

• 88% efficiency with a high 95% power factor.

• Standard Controls include: Selectable Hot Start for

stick welding and Variable Arc Control.

• Touch Start TIG

®

makes it easy to achieve great arc

starts with minimal or no tungsten contamination.

• Clever stackable case design allows you to stack up

to three units to save valuable shop floor space.

• Supports 24, 42 or 115 volt wire feeders.

• Easy access front panel with 15 amp 115 volt AC auxiliary

power receptacles with circuit breaker protection will

power your lights, grinders or gun/torch water coolers.

• Three-year warranty on parts and labor.

30

DC

3

PHASE

60

50

Hz

CV

CC

• All input voltages and frequencies are both single and three

phase rated—no phase derating necessary on single phase.

• 5-425 amp output range for all recommended processes

from TIG to arc gouging.

• Input voltage from 208-575V—this one machine is

capable of running on virtually any input power supply.

• 50 and 60 Hz operation—can be connected

anywhere in the world.

• Touch Start TIG

®

for contamination-free starts.

• 87% efficiency—low power consumption for

energy savings.

• Three-year warranty on parts and labor.