4 measuring sockets – Siemens SIMATIC NET PROFIBUS User Manual

Page 431

8.4 Measuring sockets

35

8 Appendix

Version 1.0 8/00

8.4 Measuring sockets

Normal operation

0

100

200

300

400

500

600

700

800

900

Output voltage [mV]

Signal

quality

good

critical

poor

Reduced optical system reserves

Function not guaranteed

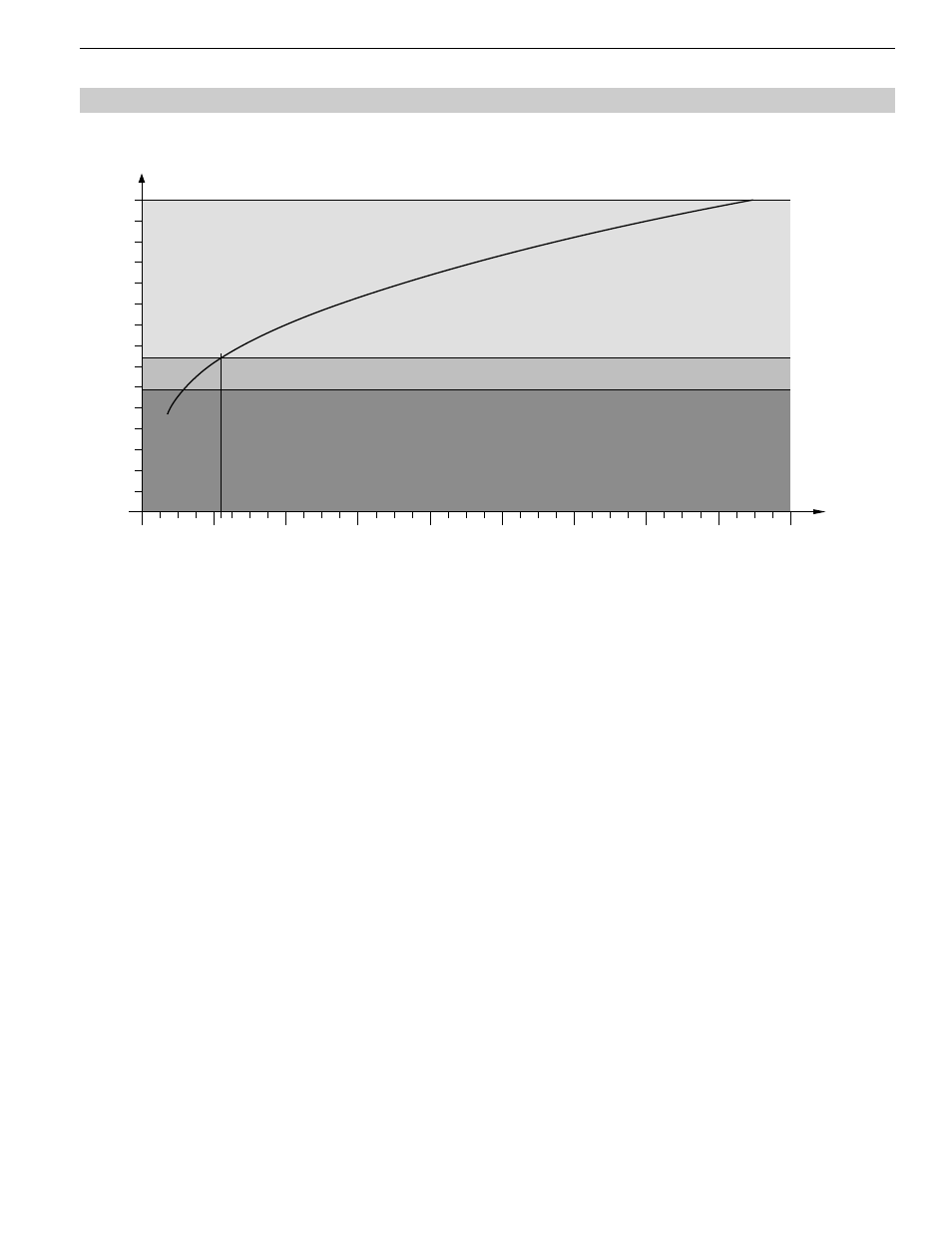

Diagram 1: Assignment of measured output voltage to signal quality.

Notes:

In order to attain a valid reading, it is necessary for the partner OLM at the other end of the optical fiber to send

regular PROFIBUS frames. This can be seen on the LED display of the partner OLM (see 5, ”LED Indicators and

Troubleshooting“, p. 25).

The output voltage at the measuring sockets is subject to many influencing factors, such as:

Ⅲ

the strength of the transmitting power of the partner OLM

Ⅲ

the ambient temperature of the optical sender and receiver

Ⅲ

attenuation of the transmitting link

Ⅲ

the transfer rates being used

The measuring sockets are therefore not intended as a substitute for a calibrated level measuring device with a

calibrated light source.

The readings taken should only serve to classify the optical signal being received in the 3 classes

Ⅲ

good

(normal operation)

Ⅲ

critical

(reduced optical system reserves)

Ⅲ

poor

(function not guaranteed)

Measurements must be taken with a conventional ungrounded and high-resistance voltmeter. A connection to the

OLM housing is not permitted either from the measuring sockets or the reference potential.