Siemens SIMATIC NET PROFIBUS User Manual

Page 381

Infrared Link Modul (ILM)

6ZB5530–3AC30–0BA1

39

Copyright

by Siemens

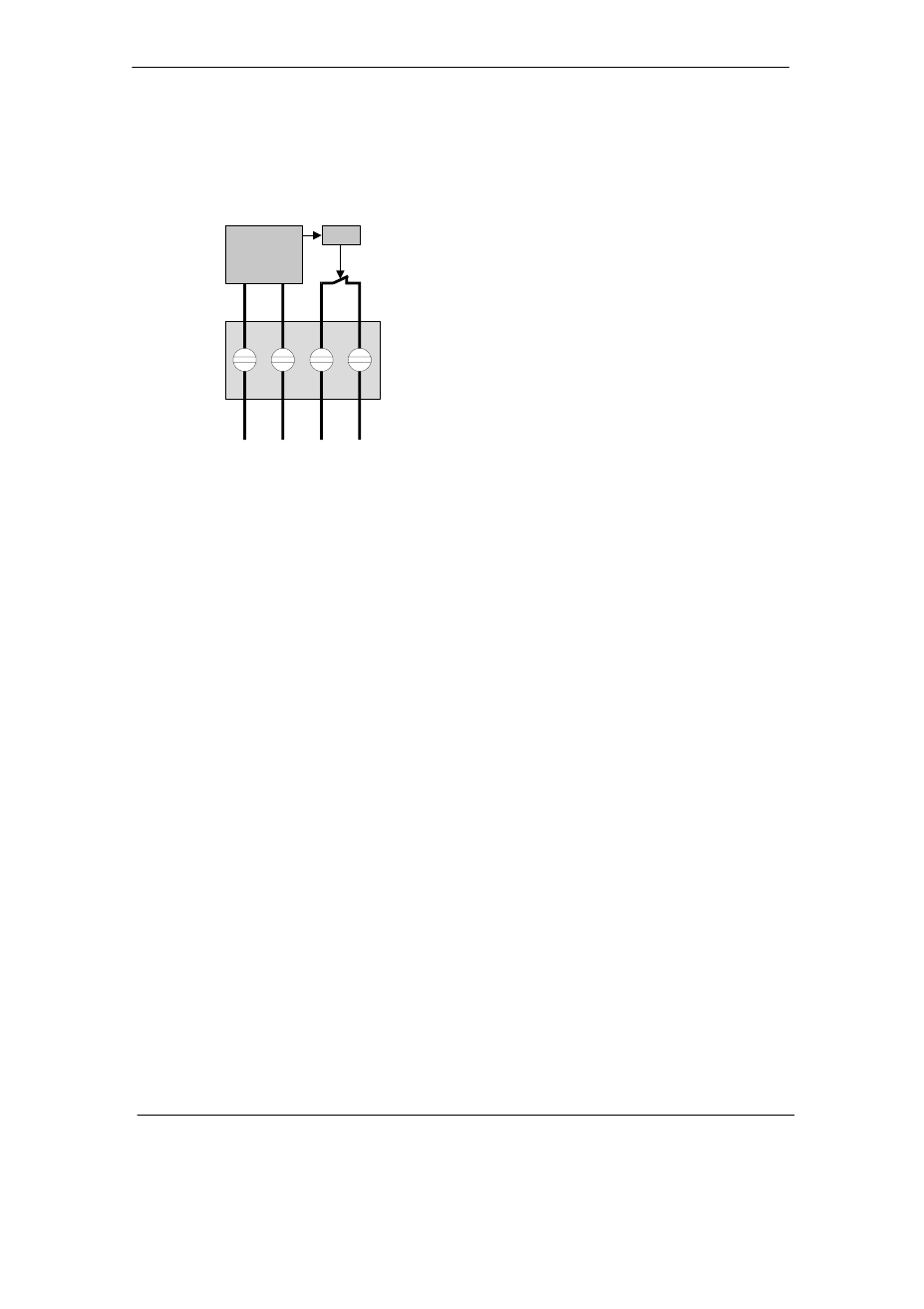

Figure 18 shows the functional wiring of the power supply and signaling contact cable. The pair of cores

connected to “

)

” and “–” supplies the power for the PROFIBUS ILM. This pair must always be wired up.

)

–

S 1

S 2

Relay

Signaling contact

(normally closed contact)

Electronics

of the ILM

Terminal block for

power supply and

signaling contact

Power supply

20 to 30 V

max. 300 mA

NEC Class 2

Power supply

max. 30 V

max. 1 A

NEC Class 2

Figure 18:

Wiring of the Power Supply and Signaling Contact

The pair of cores connected to “S1” and “S2” is used to wire the signaling contact and is only necessary if you

intend to use the signaling contact.

The signaling contact is closed in normal operation and opens if the following problems occur:

â

The device has no power supply

â

Acknowledgment pulse was not detected (acknowledgment pulse mechanism activated and configured to

trigger the signaling contact),

â

No changing reception activity on the optical receiver if this was configured to trigger the signaling contact.

â

Too much extraneous light at the optical receiver if this was configured to trigger the signaling contact.

â

Receive level low at optical receiver if this was configured to trigger the signaling contact.

The signaling contact has no electrical connection to any other components of the PROFIBUS ILM.

Limit values of the relay

â

Maximum switching power:

30 W

â

Maximum switching voltage:

30V DC;

â

Maximum switching current:

1.0 A

The voltage connected to the signaling contact must be a safety extra-low voltage complying with IEC 950/EN

60 950/ VDE 0805. According to the CUL approval you should connect the signalling contact only at the load

side of a Class 2 or Class 3 power source as defined by the National Electric Code (NEC), Article 725–2 and

the Canadian Electrical Code (CEC).