1 connecting the electrical rs 485 bus cables – Siemens SIMATIC NET PROFIBUS User Manual

Page 378

Infrared Link Modul (ILM)

6ZB530–3AC30–0BA1

36

Copyright

by Siemens

8.1

Connecting the Electrical RS 485 Bus Cables

For the RS 485 bus cable, use only shielded twisted pair cables with an outer diameter of 7.5 to 10 mm.

Appendix B lists the electrical parameters of cable types recommended in compliance with the standard.

Make sure that you connect the same cores (green or red) uniformly to all bus terminals of a cable section,

either terminal A or terminal B.

The following are recommended for field bus networks:

Terminal A: Green core

Terminal B: Red core

Do not connect any RS 485 LAN cables that are laid completely or partly outside buildings without first

protecting the network using a suitable surge voltage protector. Otherwise, lightning strikes in the area can

destroy the PROFIBUS ILM or other network components.

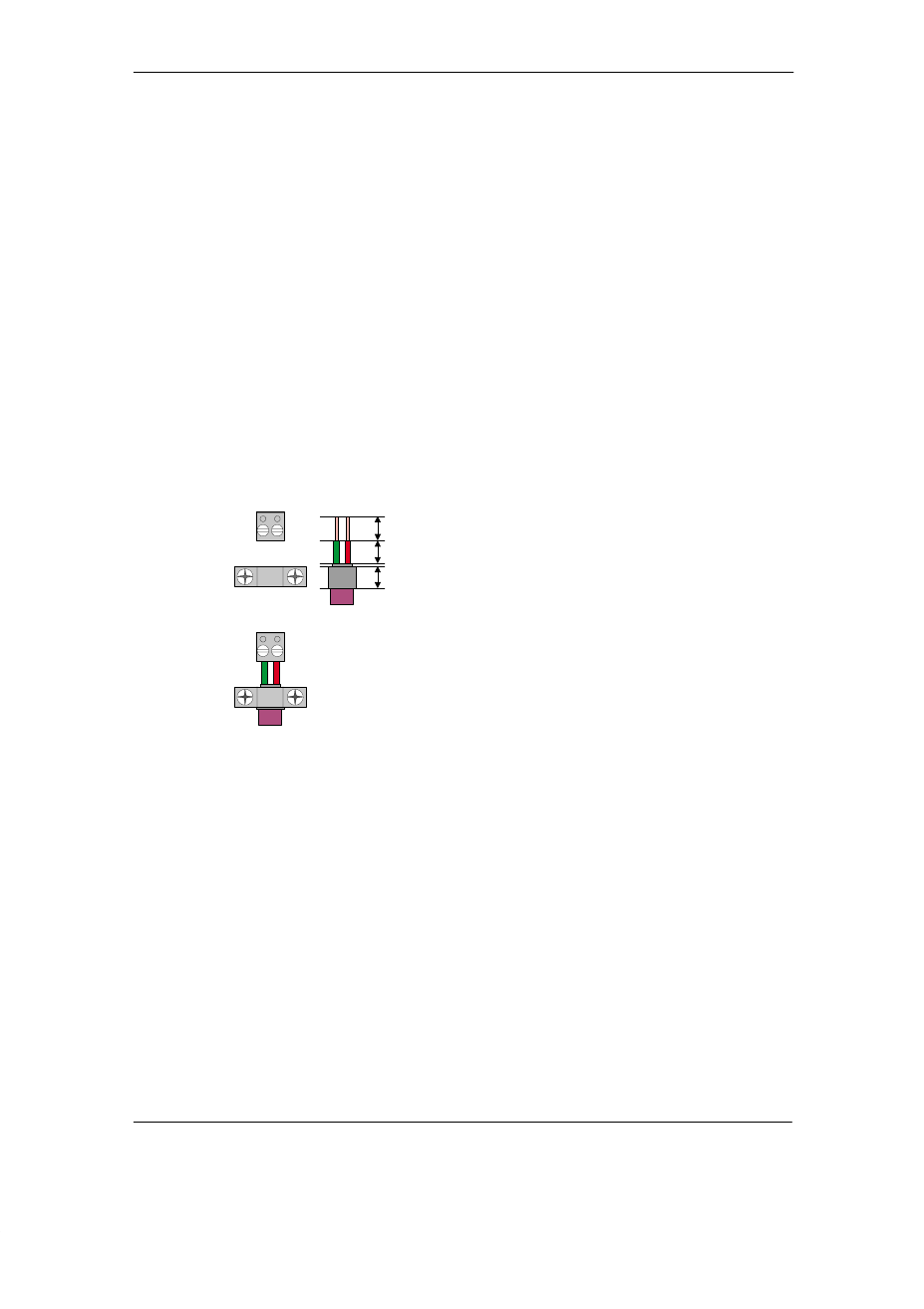

Connect the RS 485 LAN cable to the terminal block as shown in Figure 16.

The terminals marked A or B are electrically identical.

A B

A B

Terminal block

Cable clamp

Cable installed

Bare wire approx. 8 mm

Core insulation approx. 8 mm

Fold back braided shield

approx. 8 mm

Figure 16:

Connecting the PROFIBUS Cables

Fold back the braided shield over the outer jacket of the LAN cable. This provides you with a sufficiently large

cable diameter to clamp the cable.

Screw the threaded cable inlet so that if IP65 is required, the cable connection is watertight. If this is required,

PROFIBUS cables with a round cross-section and an outer diameter of 7.5 to 10 mm must be connected.

Tighten the threaded cable inlet with a torque of approx. 2.5 to 3 Nm so that the collar of the cable inlet is

sealed against the casing of the PROFIBUS ILM. When the cable is connected, the union nut of the cable inlet

must be tightened so that the cable can no longer be pulled out. When tightening the nut, make sure that the

cable does not turn with it.

If a union nut must be released again, the threaded cable inlet should be tightened again afterwards to make

sure that this is still flush against the casing.