Wiring of primary power source, 2 wiring, Primary power source – Denso RC5 User Manual

Page 172: 2 wiring of primary power source

152

7.2 Wiring of Primary Power Source

Observe the following precautions when wiring the primary power source of the robot

controller:

(1) Connect the robot power cable to a power source separate from the welder

power source.

(2) Ground the grounding wire (green) of the robot power cable.

(3) Ground the grounding terminal of the robot controller using a wire of 1.25 mm

2

or

more in size.

(4) For the robot power supply, use a grounding wire with grounding resistance of

100

Ω

or less.

(5) If the supply power source for the robot controller requires a leakage breaker, use

a high frequency-proof leakage breaker for inverters.

(6) Prepare wires of an appropriate capacity for the 200 VAC main line and other

cables according to the tables given below.

Robot Controller Power Supply Specifications

Item

Specifications

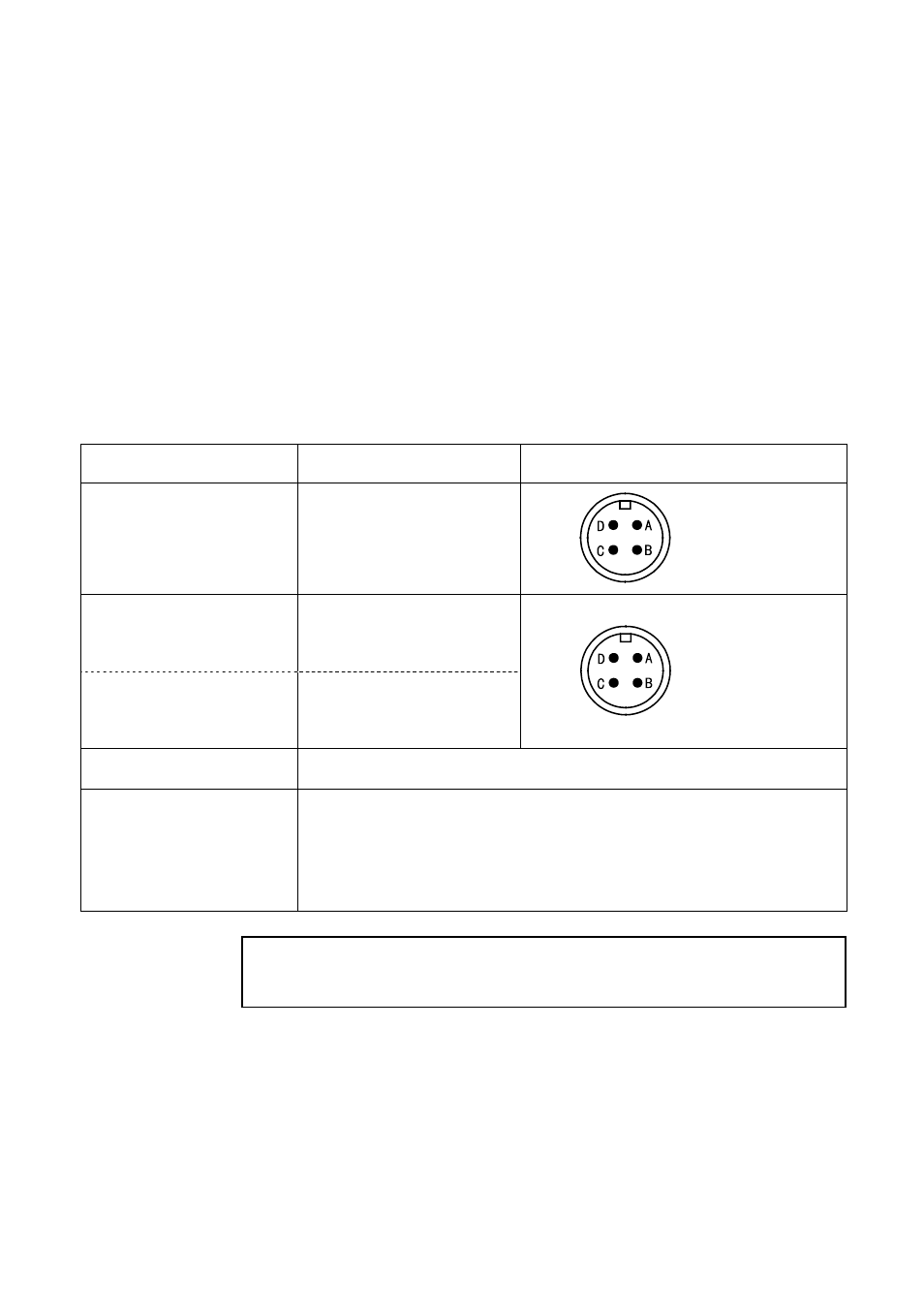

Pin assignment on power connector (CN11)

(View from the pin face of cable)

3-phase power supply

(RC5 all models)

3-phase, 200 VAC -15% to

230 VAC + 10%, 50/60 Hz

A: 200 VAC, phase R

B: 200 VAC, phase S

C: 200 VAC, phase T

D: Ground

Single-phase power supply

(RC5 for VS-D/-E, H

∗

-D,

HS-E, XYC-D)

Singe-phase, 230 VAC -10%

to 230 VAC + 10%, 50/60 Hz

Single-phase power supply

(RC5 for VC-E)

Singe-phase, 200 VAC -10%

to 230 VAC + 10%, 50/60 Hz

A: 230 VAC, phase R

B: 230 VAC, phase S

C: Not used.

D: Ground

Max. rush current when

the power is turned ON

50 A (for 1/50 or 1/60 second)

Power consumption of

robot

3.3 kVA (VM-D/HM-E)

2.0 kVA (H

∗

-D)

1.9 kVA (VS-E)

1.8 kVA (HS-E)

1.5 kVA (VS-D, XYC-D)

0.6 kVA (VC-E)

Caution: If ERROR6102 (power voltage drop) occurs when the robot is in

operation, then it may be due to an insufficient capacity of the primary

power source.

(7) Do not bundle the teach pendant cables, I/O cables or motor cables together with

high power lines such as 200 VAC lines and peripheral device cables, or route

the motor cables near high power devices (motor, welder, parts feeder, etc.).

(8) Do not route any additional cables or air tubes of end-effectors through the robot

unit. Doing so will result in broken cables or tubes.