3 unit test mode and setting fan cfm, 0 commissioning and startup (cont’d), 2 checklist prior to startup (cont’d) – Reznor YDSA Unit Installation Manual User Manual

Page 60

Form I-Y, P/N 273646R6, Page 60

Check that combustion air inlet and flue discharge openings are free of

obstructions.

If installed in California, verify that the California Warning Label is displayed. See

Paragraph 1.4.

If equipped with a high-efficiency gas heat section, verify that the condensate drain

is installed. See Paragraph 9.2, starting on page 37.

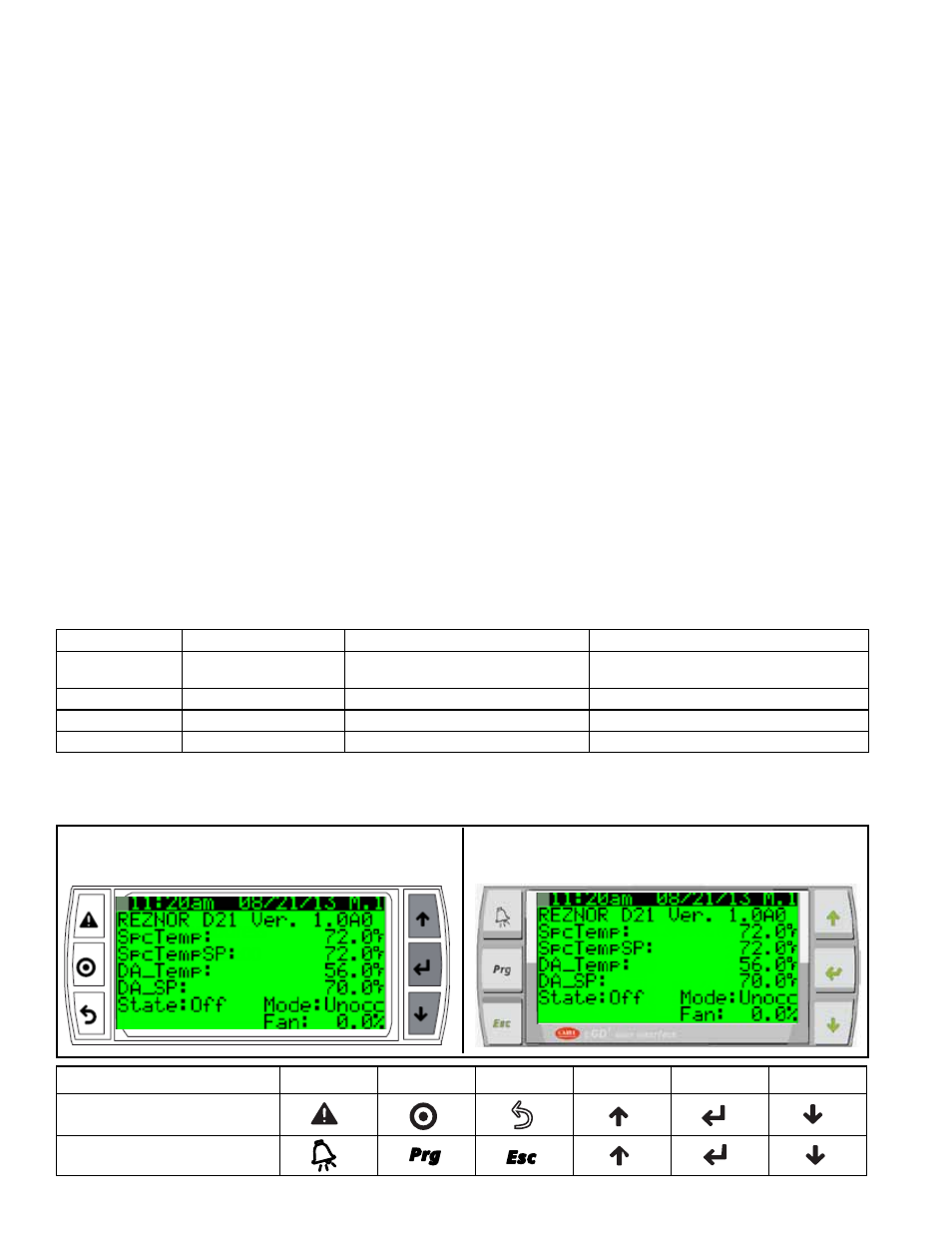

Function Key Displays

The function keys will be referred to throughout the following procedures. The unit con-

troller display or the optional remote display may be used. The function key symbols for

Alarm, Prg, and Esc differ on the remote display. See examples below for clarification.

10.3 Unit Test Mode

and Setting

Fan CFM

Test Mode Instructions

The test mode is accessed via the service menu and can only be entered when the unit

is in the OFF state. Once the test mode is enabled, it remains active for a 2-hour time

period adjustable from 0 to 4 hours. When the timer expires or test mode is disabled,

the unit will return to the OFF state.

In the Test Mode, all sequences of operation stop. Upon the Test Mode being enabled,

the following devices shall be automatically commanded:

1. The Unit Damper Position Y1 shall be automatically commanded to = 100%.

2. The Unit Supply Fan NO1 will be automatically commanded ON.

3. The optional unit Exhaust Fan will be automatically commanded ON via modbus.

4. The Unit Supply Fan Speed Y2 and optional unit Exhaust fan via modbus

communication will be automatically commanded to their maximum Speed %

setpoint values. (The maximum Fan Speed % setpoint values are initially set at the

factory and will need to be verified in the field.)

Once supply airflow is proven via Unit Supply Fan Status ID1, the user can manu-

ally select all of the remaining controller outputs to be commanded ON and OFF or

modulated between 0-100% with the exceptions shown in the Compressor Test State

Automatic Interlock Table.

Output Terminal

Output Point Name

Output Description

Interlocked Output

Y3

Comp_Mod_Cap

DX Capacity Modulation

Condenser Fan Section A NO5 = ON When

Y3 greater than 1.44 vdc

NO2

Compressor_Stg2

DX Compressor Stage 2 Start/Stop

Condenser Fan Section B NO6 = ON

NO3

Compressor_Stg3

DX Compressor Stage 3 Start/Stop

Condenser Fan Section B NO6 = ON

NO4

Compressor_Stg4

DX Compressor Stage 4 Start/Stop

Condenser Fan Section B NO6 = ON

Compressor Test State Automatic Interlock Table

Example of Unit Controller Display Key

Symbols

Example of Remote Controller Display (Option

RB5 or RB6) Key Symbols

Function Key Identification

Alarm

Prg

Esc

Up

Enter

Down

Function Key Display on the

System Controller

Function Key Display on the

Remote Controller

10.0 Commissioning and Startup (cont’d)

10.2 Checklist

Prior to Startup

(cont’d)

10.2.2 Additional Gas Heat Checklist Prior to Startup (cont’d)