Reznor YDSA Unit Installation Manual User Manual

Page 40

Form I-Y, P/N 273646R6, Page 40

Instructions for

Measuring Manifold

Pressure - Option AG71

(2-stage with one heat

section)

Gas Pressure Tap Location

Locate the 1/8” pressure tap on the manifold. (See

FIGURE 23, page 39). Close the

manual valve and connect a manometer to the 1/8” pressure tap in the manifold. Both

high-fire and low-fire pressure can be checked at the manifold pressure tap. Open the

manual valve.

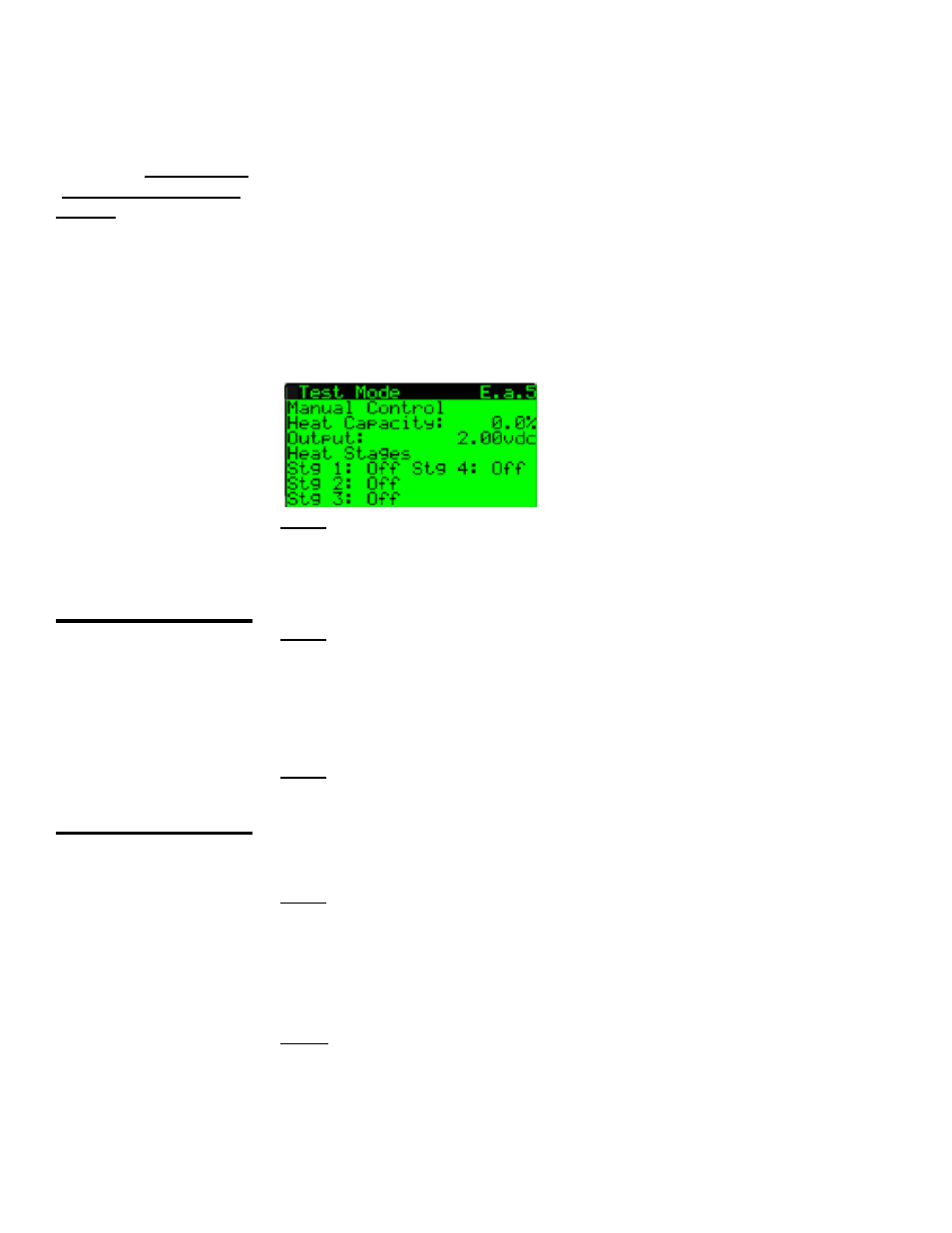

Unit Test Mode Must be Enabled - Refer to Paragraph 10.3 to enable Test Mode

Follow the instructions to enter Test Mode and proceed to Test Mode Screen E.a.5.

Manifold Pressure Measurements

From the Test Mode

Screen E.a.5:

•

Press the enter key until the cursor is flashing on the

Stg 1: field.

Press the up arrow to set the Stg 1 value to ON.

•

Press the enter key until the cursor is flashing on the

Stg 2: field.

Press the up arrow to set the Stg 2 value to ON.

Step 1 - High-Fire Manifold Pressure Reading

Using the manometer, measure the manifold pressure on high fire.

Check the pressure

with the chart on page 49. Normally adjustments to the factory settings should

not be necessary.

•

If no adjustment is required, proceed to Step 3.

•

If an adjustment is required, proceed to Step 2.

Step 2 - High Fire Manifold Pressure Adjustment

Remove the cap from the high fire adjustment screw on the two-stage valve. Adjust

the pressure setting by turning the regulator screw IN (clockwise) to increase pressure.

Turn the regulator screw OUT (counterclockwise) to decrease pressure. Replace cap.

CAUTION: DO NOT

bottom out the gas

valve regulator

adjusting screw.

This can result in

unregulated manifold

pressure causing

excess over fire

and heat exchanger

failure.

Cycle the burner by turning the value of the Stg 2 field OFF and ON to actuate the

valve. Recheck the manifold pressure and repeat Step 2 if required. If the pressure

reading is correct, set the value of Stg 2 to OFF and proceed to Step 3.

Step 3 - Low-Fire Manifold Pressure Reading

Using the manometer, measure the manifold pressure on low fire (Stg 1 ON).

Check

the pressure with the chart on page 48. Normally adjustments to the factory

settings should not be necessary.

If no adjustment is required, proceed to Step 5.

If an adjustment is required, proceed to step 4.

Step 4 - Low Fire Manifold Pressure Adjustment

Remove the cap from the low fire adjustment screw on the two stage valve. Adjust the

pressure setting by turning the regulator screw IN (clockwise) to increase pressure.

Turn the regulator screw OUT (counterclockwise) to decrease pressure. Replace the

cap. Cycle the burner by turning the value of the Stg 1 field OFF and ON to actuate

the valve.

Recheck the manifold pressure and repeat Step 4 if required.

Step 5 - Close the manual valve. Remove the manometer. Check for a leak at the

pressure tap using a leak-detecting solution.

If further unit component testing is required proceed with the instructions in Paragraph

10.3 for the remaining test mode menu screens. If further unit testing is not required,

press the enter key in succession until the cursor is flashing in the uppermost left hand

corner of

screen E.a.5 and use the up arrow key to navigate to Test Mode Screen

E.a.1. Press the enter key to select the Enable: field. Press the down arrow key to set

the value to OFF.

9.2.2 Checking Gas Pressure (cont’d)

9.2 Gas Heat Section (cont’d)

9.0 Optional Equipment including Heat Sections (cont’d)