3 other optional controls, 0 controls (cont'd), 2 supply fan control (cont’d) – Reznor YDSA Unit Installation Manual User Manual

Page 34

Form I-Y, P/N 273646R6, Page 34

Pickup Tube

for Duct work,

Option VFC3,

P/N 234821

2. Pickup Tube Locations

Duct Static (Option VFC3) Pickup Tubes - Mount the pickup tube shipped with

the unit approximately 2/3 down the length of the duct work (minimum of 10 duct

lengths). At the selected location, drill a 7/16” hole in the side of the duct. Insert the

pickup tube being sure that it is centered in the hole and attach with two #8 sheet

metal screws. Check to be sure that the hole is sealed. Connect tubing from the

sensor in the duct to the “high” connection on the transducer.

To sense atmospheric pressure, route the tubing from the “low” connection on the

transducer to one of the small holes in the cabinet panel and install a field-supplied

pickup tube designed for outdoors.

Building Pressure Control (Option VFC4) Pickup Tubes - Both pickup tubes

for building pressure control are field supplied. Install a pickup tube in the building.

To sense atmospheric pressure, route the tubing to one of the small holes in the

cabinet panel and install a field-supplied pickup tube designed for outdoors.

As determined by the application, attach the tubing from the positive (high)

pressure pickup to the “high” connection on the transducer and the reference (low)

pressure pickup tube to the “low” connection on the transducer.

3. Verify Installation and Operation - Be sure that tubing connections are correct

and attached securely. On startup, verify that there is a pressure reading displayed

on the unit controller.

Option BD5,

Firestat

(200°F),

P/N 42782

The firestat is for field installation in either the return

air or outlet air duct work. Follow instructions supplied

with the control. Comply with local building codes.

See Paragraph 7.5.3 for wiring requirements and

connections.

Option BD5, Firestat

8.3 Other Optional

Controls

Option BE18 or BE28,

Dirty Filter Switch

If dirty filter indicator Option BE18 was ordered, a dirty filter switch is in the electrical

compartment with tubing sensors placed on either side of the supply filters. If dirty

filter indicator Option BE28 was ordered, two dirty filter switches are in the electrical

compartment with tubing sensors placed on either side of the supply air filters and the

energy recovery wheel filters.

The pressure switch(es) are in the low voltage electrical compartment. Follow the

instructions in

FIGURE 20, shown below to set the dirty filter switch.

NOTE: See Tubing Color

Chart on page 26.

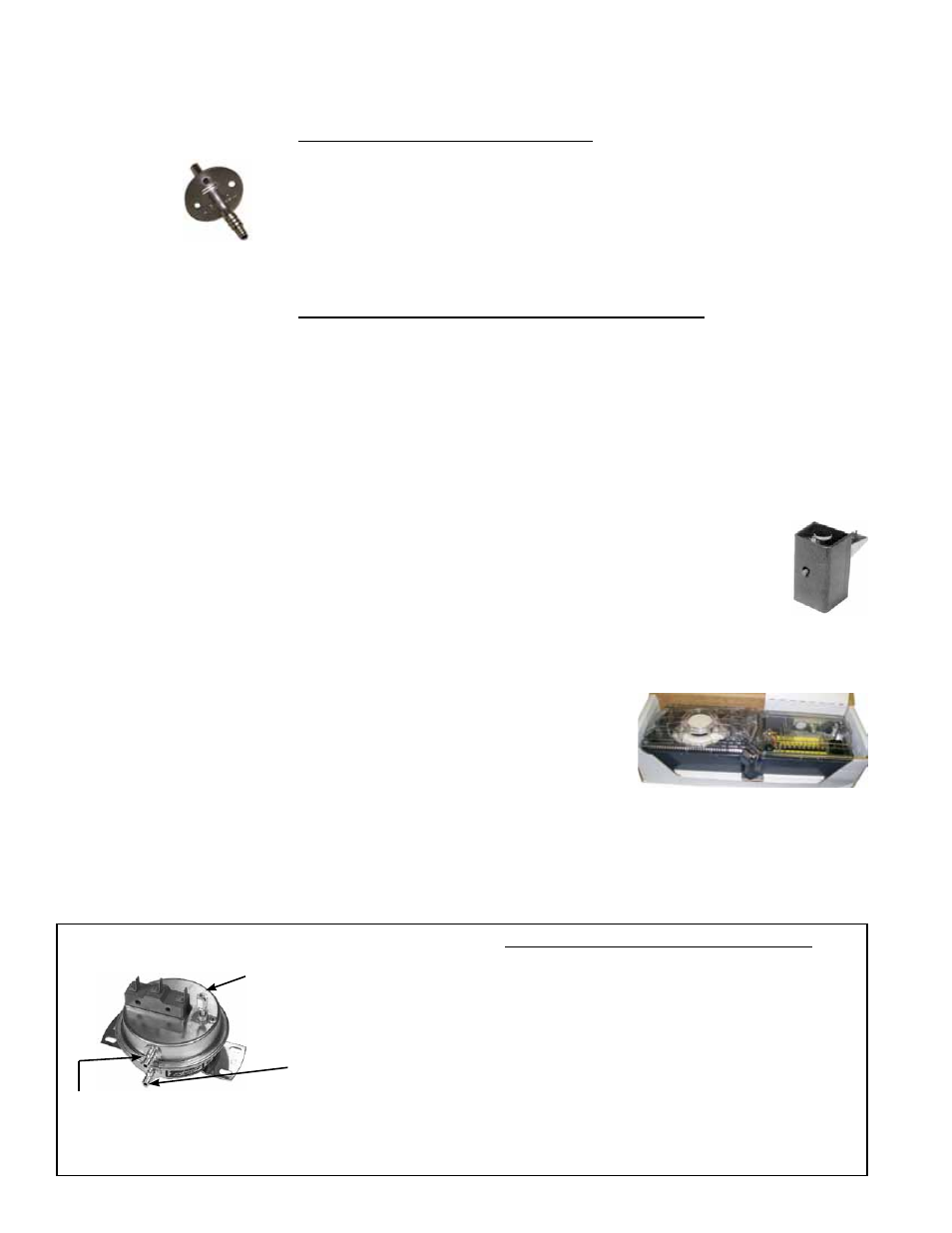

FIGURE 20 - Dirty Filter Switch, P/N 105507

Setscrew (on front of

switch) must be manually

adjusted after the system

is in operation.

Negative pressure

connection is toward the

"front or top" of the switch

(senses blower side of filters)

Positive pressure

connection is toward

the "back or bottom"

of the switch (senses

air inlet side of filters)

Instructions for Setting Dirty Filter Switch

With clean filters in place; all doors closed

(except electrical compartment); and the blower

operating, navigate to Digital Input Screen C.9

which shows point DI02 Filter_Sts.

Increase the pressure setting by adjusting the

setscrew on the switch clockwise until the filter

status value is reading OFF. At this point, adjust

the setscrew three full turns counterclockwise.

At this setpoint, the filter light will be activated at

approximately 50% filter blockage.

Option BE15, Space

CO2 Sensor

Field installed in the space, the sensor (P/N 234820) has a range of 0-2000 ppm. Fol-

low the manufacturer’s instructions for installation. Refer to Paragraph 7.5.3 for wiring

requirements and connections.

Option BE17,

Photoelectric Duct

Smoke Detector and

Sampling Tube

The photoelectric smoke detector (

P/N 159553)

used in Option BE17 is field mounted on the

duct work. Follow the manufacturer's installation

instructions. See Paragraph 7.5.3 for sensor

wiring requirements and connections.

NOTE: Tubing is field

supplied.

8.0 Controls (cont'd)

8.2 Supply Fan Control (cont’d)