2 supply fan control, 1 system controller (cont’d) – Reznor YDSA Unit Installation Manual User Manual

Page 33

Form I-Y, P/N 273646R6, Page 33

8.2 Supply Fan

Control

The main controller is programmed to control the fan to operate the unit in two modes:

Occupied and Unoccupied

The supply fan (blower) starts/stops automatically through a local time of day schedule

or remote contact closure commanding the system to occupied mode. If the controller

is connected to a building automation system, other external controllers can control the

mode of operation.

Upon a command for occupied mode, the supply fan starts and runs continuously.

There is a differential pressure (air proving) switch that indicates proof of fan operation.

The supply fan is subject to safety devices, such as duct high limit switches, fire alarm

relays, smoke detectors, low temperature limits, fan status, and other devices which

can turn the supply fan OFF.

If the unit is in the unoccupied mode, the supply fan is turned OFF and will only run

intermittently to maintain night setback/setup space conditions.

Pressure Tubing Color Codes

Pressure Tap

Std or Optional Color

Supply Fan Pressure Tap (High Side)

Standard

BLUE

Inlet Plenum Tap (Low Side)

Standard

CLEAR

Exhaust Fan Ring Tap (High Side)

Option PE or EW YELLOW

Exhaust Fan Inlet Plenum Tap (Low Side) Option PE or EW CLEAR

Dirty Filter Switch - High Side

Option BE18

RED

Dirty Filter Switch - Low Side

Option BE18

CLEAR

Dirty Filter Switch for ERV Wheel Filters

- High Side

Option BE28 with

EW Option

GREEN

Dirty Filter Switch for ERV Wheel Filters

- Low Side

Option BE28 with

EW Option

CLEAR

Factory-installed tubing for pressure sensors is color coded.

8.1 System

Controller

(cont’d)

Senses

Option Installation and Function

2 Speed Fan Control

Based on Active Heating

or Cooling Mode

VFC1

Supply airflow is factory set to order specifications but is adjustable

via the unit controller.

Duct Static Pressure

(0 to 2.5" iwc)

VFC3

Requires field installation of sensor in the supply duct. See

instructions below and in the sensor manufacturer's installation

form.

Building Static Pressure

(-0.5 to 0.5" iwc)

VFC4

Field installed sensor to monitor building pressure. Requires field

installation of tubing and sensor. See instructions below and in the

sensor manufacturer's installation form.

Summer/Winter

Adjustable Constant

Volume Control

VFC9

Supply airflow is factory set to order specifications but is adjustable

via the unit controller.

Sensor Options for

Variable Frequency

Drive

Duct pressure sensing (Option VFC3) has a range of 0 to 2.5”. Building pressure sens-

ing (Option VFC4) has a range of -0.5 to +0.5”. Both pressure transducers sense differ-

ential or gauge (static) pressure and convert this pressure difference to a proportional

high level analog output (0-10Vdc) for both unidirectional and bidirectional pressure

ranges. The transducers are designed to be used with air or nonconducting gases. The

operating and compensated temperature limits of the transducers are 0˚F to +150˚F

(-18˚C to +65˚C).

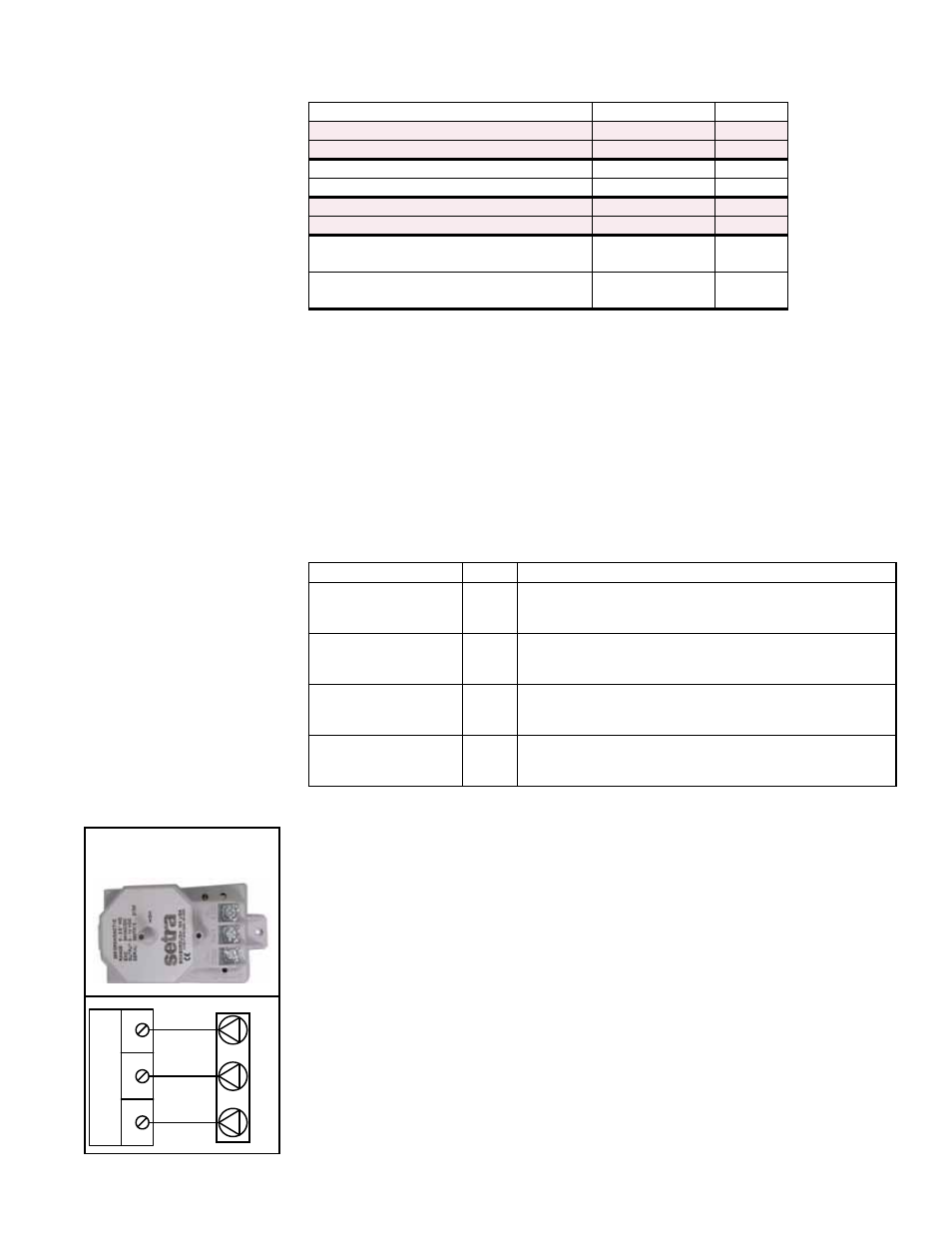

The transducer is mounted in the control compartment. Installation of the tubing and

pickup tubes must be done at the site. The location and position of the sensor pick-

ups is important. Follow the instructions below and the manufacturer’s instructions for

installing pickup tubes and tubing.

Pressure Sensors,

Option VFC3 and VFC4

Unit Control Panel

16

U7

15

Pressure Tranducer

COM

OUT

EXC

Ground

0-10Vdc

24Vdc

1.

Tubing Requirements

All tubing is field supplied. The transducer is equipped with 1/4” O.D. pressure

fittings for the pressure signal connection. Both the positive (high) pressure port

and the reference (low) pressure port are located on the front of the transducer,

labeled “HIGH” and “LOW” respectively.

For best results (shortest response times), 3/16” I.D. tubing is suggested for tubing

lengths up to 100 feet (30M), 1/4” I.D. for tubing lengths up to 300 feet (91M), and

3/8” I.D. for tubing lengths up to 900 feet (274M).

Tranducer in the

Control Compartment