0 electrical and wiring (cont'd), 5 control wiring (cont’d) – Reznor YDSA Unit Installation Manual User Manual

Page 28

Form I-Y, P/N 273646R6, Page 28

7.5.2 Sensor Wiring

24V Field Control

Wiring Length and

Size Requirements

Total Wire Length

Minimum Recommended Wire Size

150 ft (45M)

#18 gauge shielded wire

250 ft (76M)

#18 gauge shielded wire

350 ft (106M)

#14 gauge shielded wire

Discharge Air

Temperature Sensor,

P/N 222753 - applies to

all installations

The manufacturer recommends for optimum temperature control performance that the

analog and digital inputs (CO

2

and air quality sensors) that are connected to the main

controller have a <3% wattage drop and be routed to the unit in one of the following

manners:

1) In separate conduits, isolated from 24 VAC controls and line voltage power to the

unit,

OR

2) If the digital sensor wires are to be run in the same conduit as the 24 VAC control

wiring, the wiring

MUST be shielded cable and bundled separately from the 24

VAC control wiring. The shield

MUST be drained at the unit and taped on the

opposite end.

Comply with the digital control sensor wire gauge and length requirements in the table

below.

Maximum Sensor

Wire Length for

less than 1°F

Signal Error

Wire Gauge Maximum Sensor Wire Length (Digital Control)

14 AWG

800 ft (244M)

16 AWG

500 ft (152M)

18 AWG

310 ft (94M)

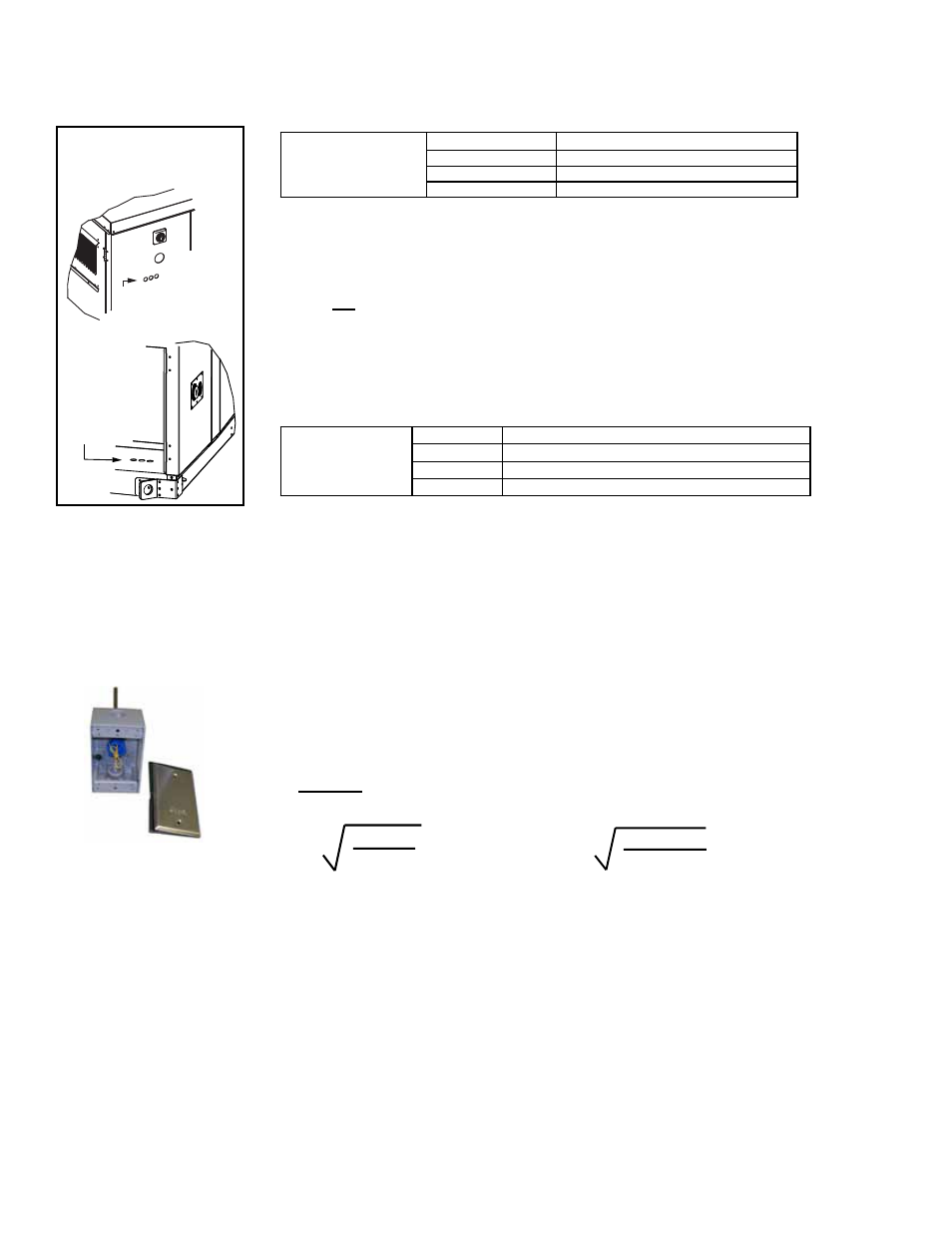

7.5.3 Field Wiring by

Control Option

Depending on which field-installed control option was ordered, the unit will operate in

response to a signal from the control. Dotted wires (lines) on the diagrams designate

field wiring. Factory wiring is shown as a solid line.

The discharge air temperature sensor is shipped with every unit and must be field

installed in the duct work. Placement of the discharge air sensor in the duct work is

critical to the correct operation of the system in both the cooling and heating modes.

Location is especially important when installing a unit with dual heat sections; refer to

the information in

FIGURE 15 on page 22.

1. Determine the appropriate distance from the unit. Be sure there is sufficient

distance from the outlet to have a good mixture of discharge air temperature.

According to the latest edition of AMCA Standard 201, in straight ducts, the air

is typically well mixed a minimum of five equivalent duct diameters from the

discharge of the unit with equivalent duct diameter defined as equal to the square

root of 4AB/3.14. “A” and “B” are the duct cross-sectional dimensions.

Example: Supply duct work cross-sectional dimension is 24" x 12"

(610mm x 305mm).

5 x

4 x 12 x 24

3.14

= 96 inches

5 x

4 x 305 x 610

3.14

= 2435mm

Locate the sensor a minimum of 96" (2435mm) from the outlet of the unit.

NOTE: If the length of the discharge duct is less than 8 ft (2.4M), a mixing vane is

recommended for mixing the discharge air.

Do not mount the sensor in the duct work after a split in the supply as that will

cause loss of control in the duct that does not house the sensor.

2. Determine the location and orientation of the sensor. The position of the

sensor in the duct is also important. In horizontal duct work, locate the sensor

assembly in the top, middle of the duct with the sensor probe extending vertically

down into the center of the airstream.

In vertical duct work, locate the sensor assembly in the middle of the side of the

duct that corresponds with the top middle of the discharge outlet.

3. Attach the sensor. Mark the selected location and drill a 7/16" hole. Insert

the probe into the hole. Be sure that the blue plastic fitting holding the probe

is centered in the hole. Attach with two No. 8 sheet metal screws (do not

overtighten). Check to be certain that the hole is sealed.

Control Wiring or Tubing

Entrances Below the

Supply Wiring Entrance

on the Outer Panel

Control Wiring or

Tubing Entrances

through the

Bottom Panel

FIGURE 19 - Control

Wiring or Tubing

Entrance Locations

•

Shipped with the unit for

installation in the Supply

Air Duct

7.5 Control Wiring (cont’d)

7.0 Electrical and Wiring (cont'd)