4 propane combustion calibration – AERCO Innovation (G-14-2265 and above) User Manual

Page 59

Innovation Water Heaters Installation, Operation & Maintenance Manual

CHAPTER 4 – INITIAL START-UP

OMM-0078_0L

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 59 of

206

GF-128

Phone: 800-526-0288

PRI: 11/25/2014

NATURAL GAS Combustion Calibration – Continued

Combustion Calibration Readings

Valve

Position

Oxygen (O

2

) %

Nitrogen

Oxide (NOx)

Carbon

Monoxide (CO)

Flame

µA

80%

6.5% ± 0.2%

<20 ppm

<100 ppm

> 6

60%

7.5% ± 0.2%

<20 ppm

<100 ppm

> 6

50%

8.0% ± 0.2%

<20 ppm

<100 ppm

> 6

40%

8.0% ± 0.2%

<20 ppm

<100 ppm

> 6

30%

8.3% ± 0.2%

<20 ppm

<100 ppm

> 5

20%

8.0% ± 0.2%

<20 ppm

<100 ppm

> 4

16%

5.8% ± 0.2%

<20 ppm

<100 ppm

> 4

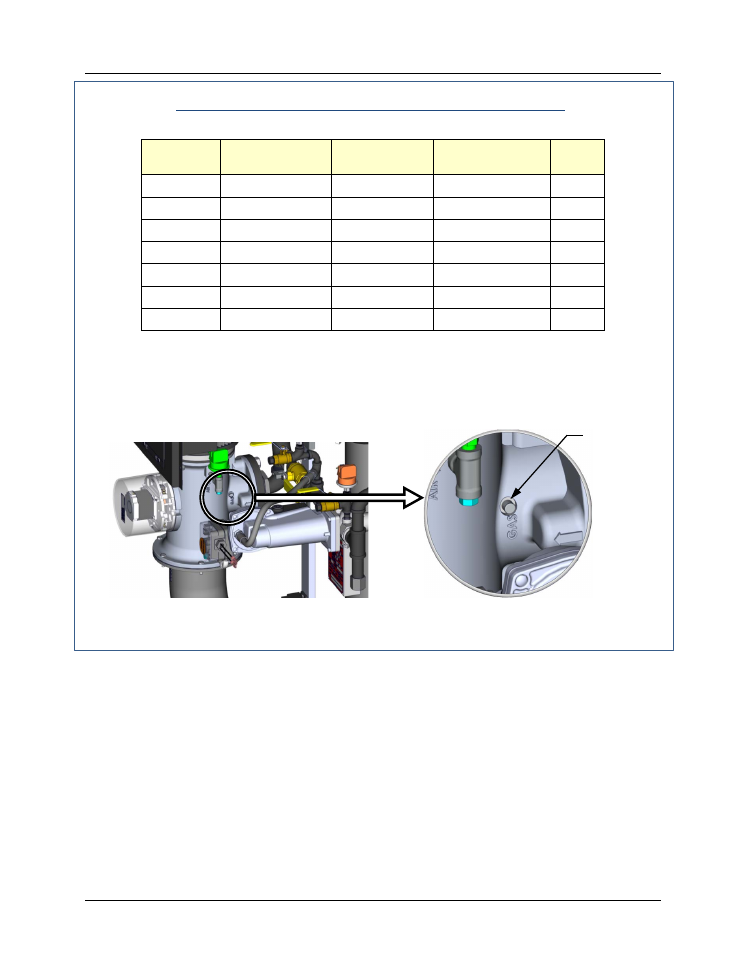

23.

If the oxygen level at the 16% valve position is too high and the Blower voltage is at the

minimum value, you can adjust the idle screw (TAC valve), which is recessed in the top of

the Air/Fuel Valve. Rotate the screw 1/2 turn clockwise (CW) to add fuel and reduce the O

2

to the specified level. Recalibration MUST be performed again from 60% down to 16% after

making a change to the idle screw (TAC valve).

Figure 4-5. TAC Valve Adjust (Idle Screw)

This completes the NATURAL GAS combustion calibration procedure.

4.4 PROPANE COMBUSTION CALIBRATION

IMPORTANT

The unit is shipped from the factory set up for either Natural Gas or Propane as

specified by the Style Number on the Sales Order. Complete the instructions

below only if your unit has been set up to run on Propane.

The Innovation Heater is combustion calibrated at the factory prior to shipping. However,

recalibration as part of initial start-up is necessary due to changes in the local altitude, gas BTU

content, gas supply piping and supply regulators. Start-Up & Registration Test Data sheets are

shipped with each unit. These sheets must be filled out and returned to AERCO for proper

Warranty Validation.

TAC VALVE

IDLE SCREW