6 test hose bib connection – AERCO Innovation (G-14-2265 and above) User Manual

Page 21

Innovation Water Heaters Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

OMM-0078_0L

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 21 of

206

GF-128

Phone: 800-526-0288

PRI: 11/25/2014

WHM Ball Valve Installation – Continued

4.

AERCO recommends that another pipe nipple and union be attached to the valve inlet

prior to connecting the cold water supply piping.

5.

Tighten all pipe connections after the valve is properly positioned.

6.

Connect the 4-pin Molex connector on the valve to the mating connector on the Innovation

harness at the rear of the unit.

7.

This completes the actuator-controlled ball valve installation.

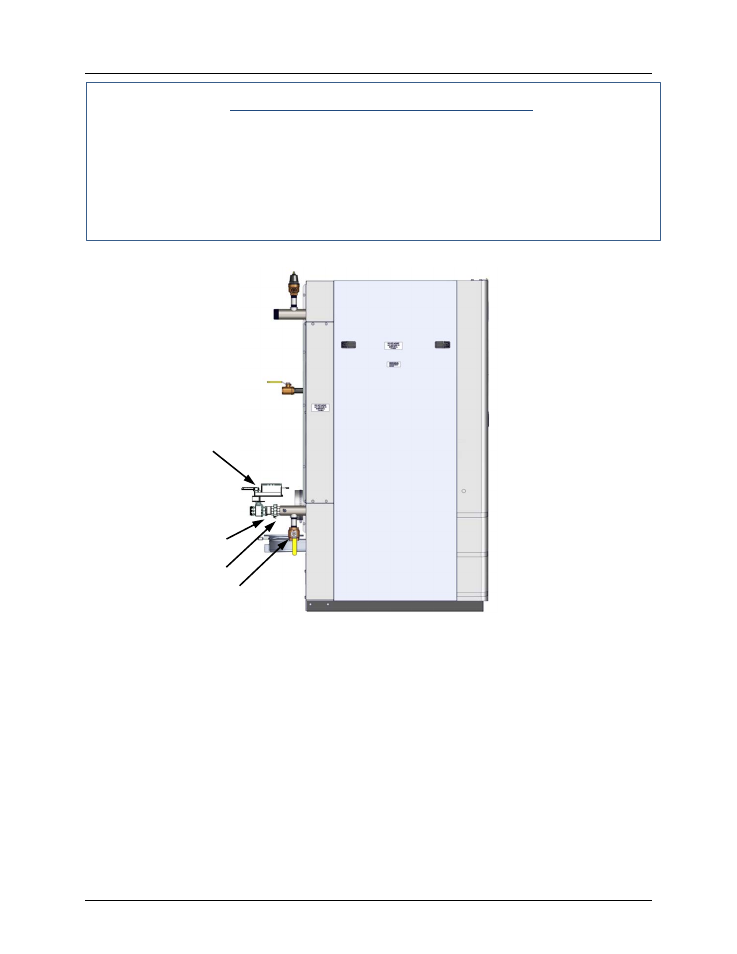

Figure 2-3b. Innovation Water Heater Equipped With Sequencing Valve

2.6 TEST HOSE BIB CONNECTION

A Test Hose Bib connection, upstream of the shut off valve on the hot water outlet, is required

for startup and testing (Figure 2-4). The pipe diameter should be a minimum of 3/4". The Test

Hose Bib cannot be omitted.

HEATER DRAIN VALVE

2” NPT UNION

BALL VALVE

WITH ACTUATOR

2” NPT

- AERClean (12 pages)

- ProtoNode Gateway Rev 1 (with internal LEDs) (64 pages)

- ProtoNode Gateway Rev 3 (with external LEDs) (126 pages)

- Control System (ACS) (144 pages)

- Belimo F6...HD/HDU Series Valve (44 pages)

- Belimo AF120-S US Actuator (9 pages)

- Belimo AMX24-MFT Actuator (9 pages)

- Belimo GKX24-MFT Actuator (9 pages)

- Belimo Motorized Valves Installation (20 pages)

- BMS II BOILER (108 pages)

- BMS II BOILER MODBUS Communication (100 pages)

- BMS 168 (86 pages)

- Boiler Valve Controller (BVC) PRIOR to Serial-12-840-1 (35 pages)

- Boiler Valve Controller (BVC) (38 pages)

- Buffer Tanks (14 pages)

- Combination Control Panel (CCP) (4 pages)

- XPC GATEWAY Communications (193 pages)

- Domestic Water Storage Tank (19 pages)

- Steam Traps (6 pages)

- X100 – Inhibitor (4 pages)

- AM Series Boiler User Manual (156 pages)

- AM Series Boiler Cascade Sequencer Controller (26 pages)

- AM Series Boiler Modbus Interface Manual (18 pages)

- BMK 1.5 LN October 2012 (166 pages)

- BMK 1.5 LN July 2011 (152 pages)

- BMK 1.5 LN June 2010 (123 pages)

- BMK 1.5 LN May 2009 (111 pages)

- BMK 1.5 LN Dual Fuel Feb 2013 (162 pages)

- BMK 1.5 LN Dual Fuel June 2010 (139 pages)

- BMK 1.5 LN Dual Fuel Jan 2009 (126 pages)

- BMK 1500-2000 (188 pages)

- BMK 1500DF (196 pages)

- C-More Control Panel (162 pages)

- BMK 2.0 LN October 2012 (172 pages)

- BMK 2.0 LN Natural Gas (SN G-11-1861 and above) (170 pages)

- BMK 2.0 LN Nat. Gas June 2010 (125 pages)

- BMK 2.0 LN Natural Gas 2008 (111 pages)

- BMK 2.0 LN Nat. Gas for Mass. only (113 pages)

- BMK 2.0 LN Dual Fuel Serial G-11-2402 and UP (160 pages)

- BMK 2.0 LN Dual Fuel Nov 2010 (139 pages)

- BMK 2.0 LN Nat. Gas (112 pages)

- BMK 2.0 LN for Mass. only (114 pages)

- BMK 3.0 LN Dual-Fuel Series Gas Fired Low NOx Boiler System (136 pages)

- BMK 3.0 LN Natural Gas July 2011 (129 pages)

- BMK 3.0 LN Nat. Gas Jan 2011 (129 pages)