13 fault relay terminals, 14 aux relay terminals, 13 flue gas vent installation – AERCO Innovation (G-14-2265 and above) User Manual

Page 33

Innovation Water Heaters Installation, Operation & Maintenance Manual

CHAPTER 2 – INSTALLATION

OMM-0078_0L

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 33 of

206

GF-128

Phone: 800-526-0288

PRI: 11/25/2014

2.12.13 FAULT RELAY Terminals

The fault relay is a single pole double throw (SPDT) relay having a normally open and normally

closed set of relay contacts that are rated for 5 amps at 120 VAC and 5 amps at 30 VDC. The

relay energizes when any fault condition occurs and remains energized until the fault is cleared

and the CLEAR button is depressed. The Fault Relay connections are shown in Figure 2-12.

2.12.14 AUX RELAY Terminals

Each unit is equipped with a single pole double throw (SPDT) auxiliary relay that is energized

when there is a demand for heat and de-energized after the demand for heat is satisfied. The

relay is provided for the control of auxiliary equipment, such as pumps and louvers, or can be

used as a unit status indictor (firing or not firing). Its contacts are rated for 120 VAC @ 5 amps.

Refer to Figure 2-12 to locate the AUX RELAY terminals (N.C., COM, & N.O.) for wiring

connections.

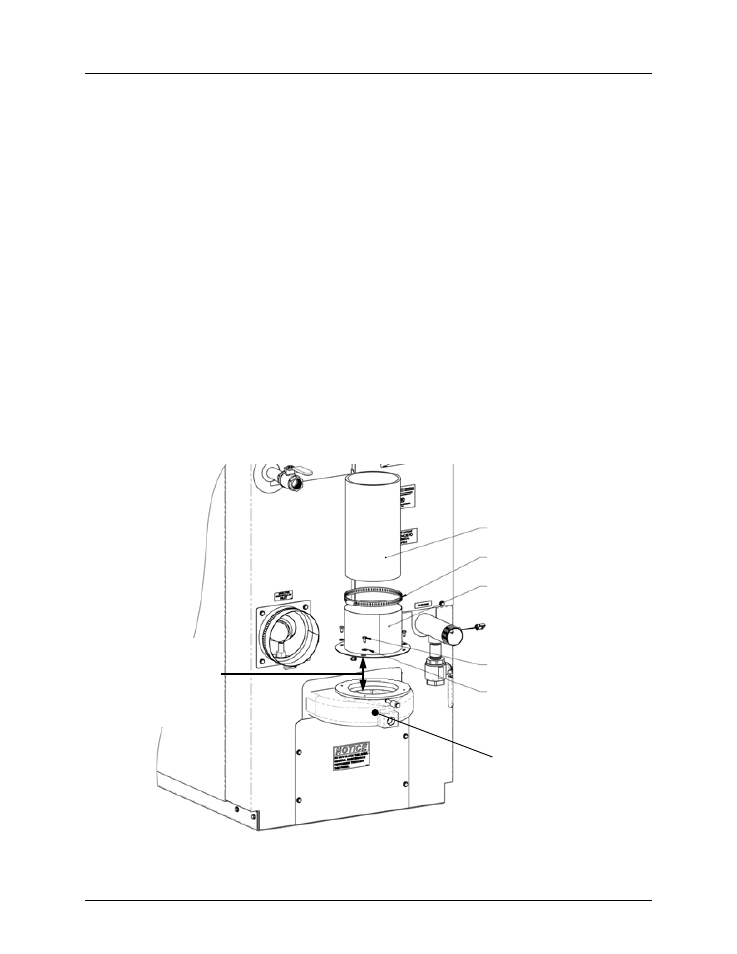

2.13 FLUE GAS VENT INSTALLATION

AERCO Gas Fired Venting and Combustion Air Guide, GF-5050 must be consulted before any

flue or combustion air venting is designed or installed. Suitable, U/L approved, positive

pressure, watertight vent materials MUST be used for safety and UL certification. Because the

unit is capable of discharging low temperature exhaust gases, the flue must be pitched back

towards the unit a minimum of 1/4" per foot to avoid any condensate pooling and to allow for

proper drainage. In addition, you must add a bead of high temperature red silicon sealant (such

as Permatex Hi-Temp Red RTV or Loctite Superflex Red High Temp RTV) between the exhaust

manifold and the mating flange of the exhaust connector, as shown in Figure 2-13.

Figure 2-13. Exhaust Vent Connection

VENT PIPE

WORM-DRIVE HOSE CLAMP

EXHAUST CONNECTOR

1/4" CAP SCREW [4X]

1/4" FLAT WASHER [4X]

CLEAN BOTH

SURFACES, THEN

APPLY HIGH TEMP

RED SILICON

SEALANT HERE

EXHAUST MANIFOLD