Brookfield DV-III Ultra Rheometer User Manual

Page 77

Brookfield Engineering Laboratories, Inc.

Page 77

Manual No. M98-211-E0912

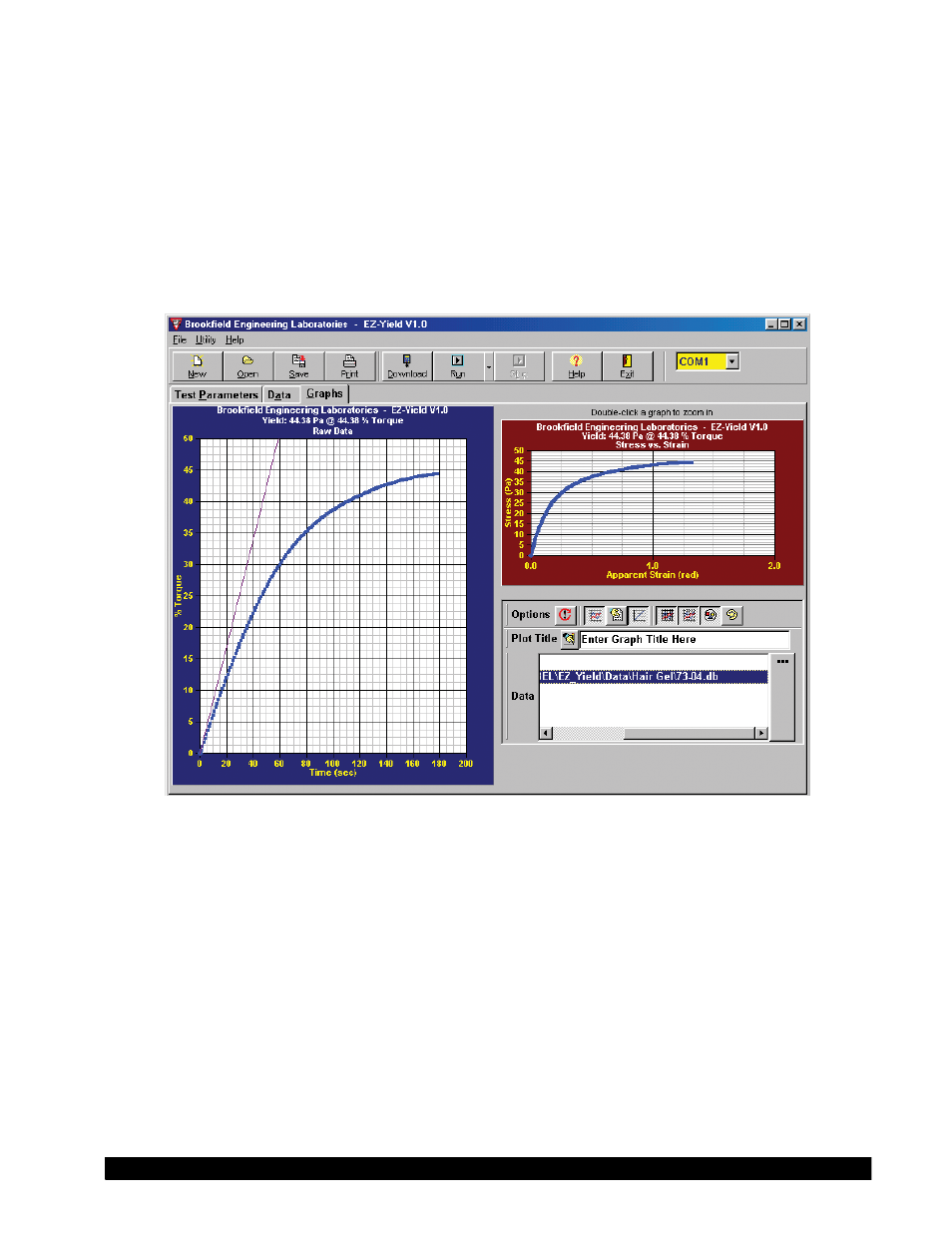

The spindle was immersed to the primary immersion mark and pre-shear was turned off. Zero was

turned on and a nominal “zero” speed of 0.1 rpm was chosen. This allows the motor to reset the

torque to zero prior to running the test. Occasionally, the spindle rotates a bit while being lowered

into the sample. This moves the torque sensor away from zero. It is usually desirable to reset it to

zero before starting the measurement. Run speed was set to 0.1 rpm. Often, 0.5 rpm is selected

and is a good starting point when establishing test parameters. In this case, a slow test was desired

so test speed was set intentionally low. Low and high yield limits (for Q.C.) were ignored.

This test resulted in a good mid-range torque of 44.5% at the yield stress, which was reported as

44.38 Pa.

Figure IV-63: Hair Gel Sample

IV.8.5.2 Example Application: Hand Cream

Hand cream is typically packaged in a small jar. The small V-73 spindle did not provide enough

torque signal (less than 10% on the RVDV-III Ultra Rheometer) so the larger V-72 spindle was

used. The jar was too shallow to completely immerse the spindle so the secondary immersion mark

was used. This provided just enough torque at the yield point for a satisfactory test. Pre-shear was

turned off. Zero was turned on and a low test speed of 0.1 rpm was selected. Torque reduction was

left at the default setting of 100%. Q.C. limits were turned off (by selecting zero for their values).

The base increment (data interval) was left at the default 1,000.

Upon conclusion of the test, individual data points were widely spaced because yield was reached so

quickly. In this case, either a lower Run Speed might be desired or a smaller Base Increment. Both

would increase the density of data points and result in a more accurate or repeatable test result.