EFCO S5500 SSG Captured User Manual

Page 67

EFCO CORPORATION 6/2012

PART NO. Y556

Page 67 of 81

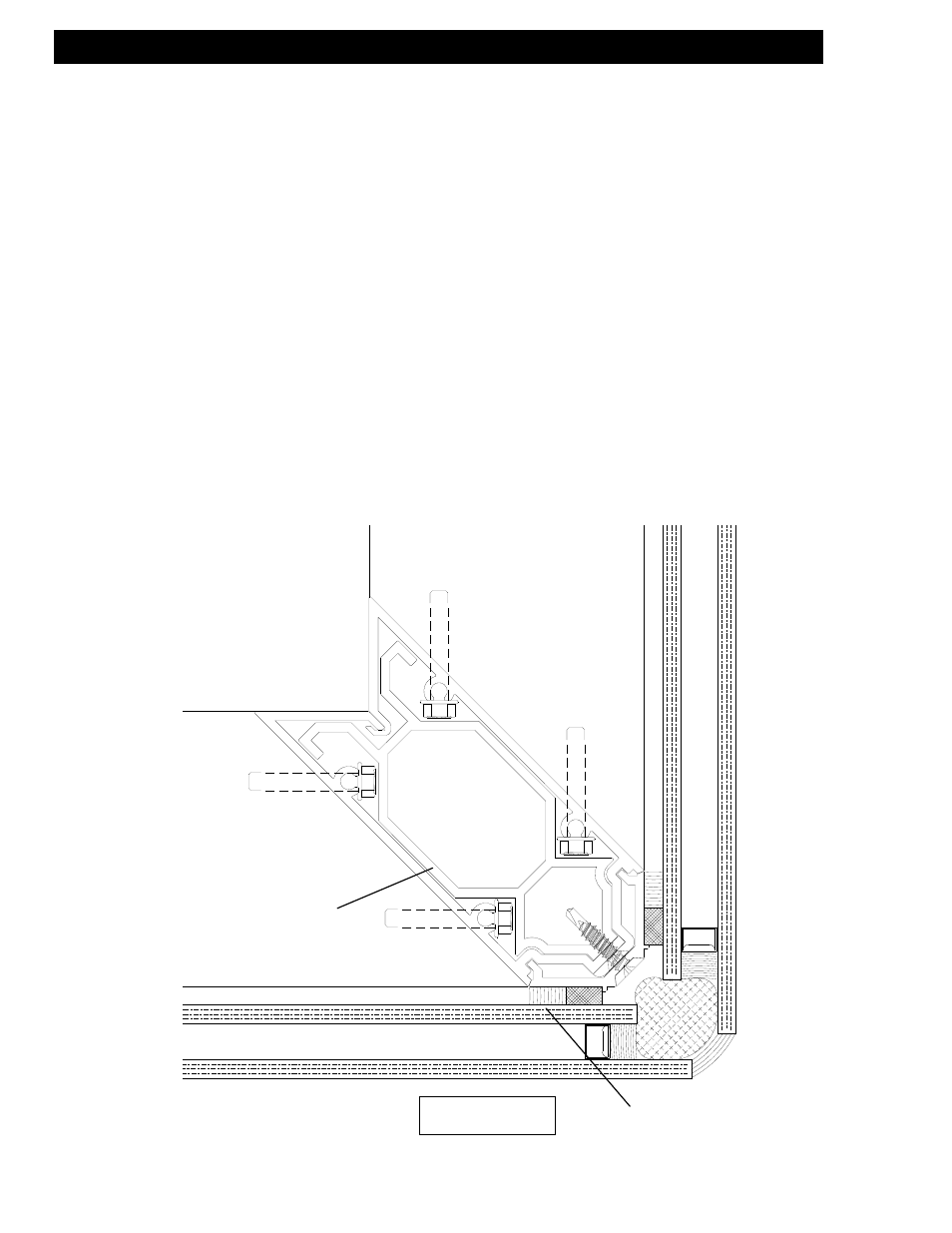

S-5500 SSG and Captured Corner Mullion Installation Instructions

Section X: Vertical Splice Joints

Installation for SSG System

STEP #1 LOCATE SPLICE JOINTS

A. Splice joints should occur at spandrel areas (if possible). Refer to the approved shop

drawings for actual locations. The vertical structural glazed system should be spliced as

close as possible to a horizontal to minimize the shear stress imposed on the vertical

structural silicone joint.

B. The mullion splice must be field assembled in the top of the lower mullion after the corner

frames have been set into the opening and anchored at the sill.

C. GENERAL NOTE: The following pages depict a splice joint of 1/2”. This will allow plus or

minus 1/4” of movement for each splice location. Thermal expansion and live deflection

requirements should be considered when determining the location and quantities of

splice joints. If the total amount of movement cannot be accommodated locating splices

at every other floor, or alternately at each floor, expansion horizontals or some

alternative method should be used. Contact EFCO for further evaluation.

D. Refer to this section for pressure plate and cover splice locations, mullion splice locations,

and sealing instructions.

E. Once a final check of the expansion joint placement and mullion position is made, final

match drilling of the mullion through the anchor holes may be completed.

Mullion splice sleeve with

bond breaker tape.

PLAN VIEW

VERTICAL STRUCTURAL

SILICONE JOINT