EFCO S5500 SSG Captured User Manual

Page 27

EFCO CORPORATION 6/2012

PART NO. Y556

Page 27 of 81

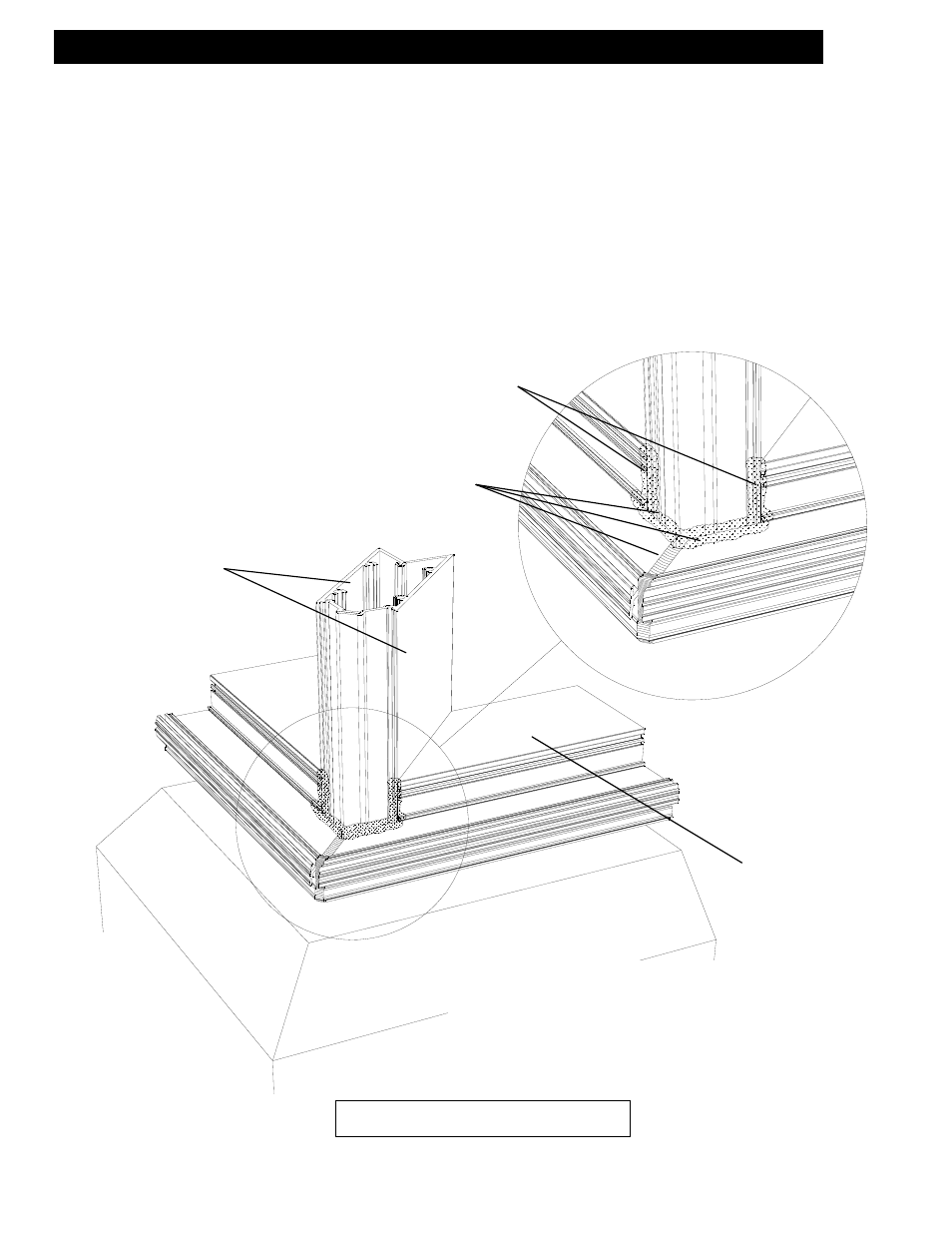

S-5500 SSG and Captured Corner Mullion Installation Instructions

Section V: Glazing Preparation (Captured)

STEP #1 SEAL JOINTS AT CORNER HEAD AND SILL AND AT CORNER MULLION

A. Seal between the mitered ends for the heads, sills, and the corner mullion to form a

water-tight joint as shown in the detail below. The sealant must not obstruct or

interfere with the areas of the head or sill where the cover will engage. Note that this is

a critical primary seal.

B. Before applying the corner mullion glazing adapter, apply two beads of sealant to the

corner mullion as shown below at each intersection of head, sill, and intermediate

horizontal. The corner mullion glazing adapter must be set immediately after this step

before the sealant begins to cure.

SILL AT CAPTURED CORNER

Seal between the mitered ends of the

sills and the corner mullion. Fill all

voids completely and tool smooth.

Apply two beads of sealant in the

reglets of the corner mullion where

the corner mullion glazing adapter

mates into the corner mullion.

Note: The corner mullion glazing adapter

must be set immediately after this step

before the sealant begins to cure.

Note: Skip to page 36 for

the next step required for

the SSG corner mullion

application.

CORNER

MULLIONS

CAPTURED

SILL