Af900pc – Dynalco AF-900PC Air/Fuel Ratio Controller User Manual

Page 46

45

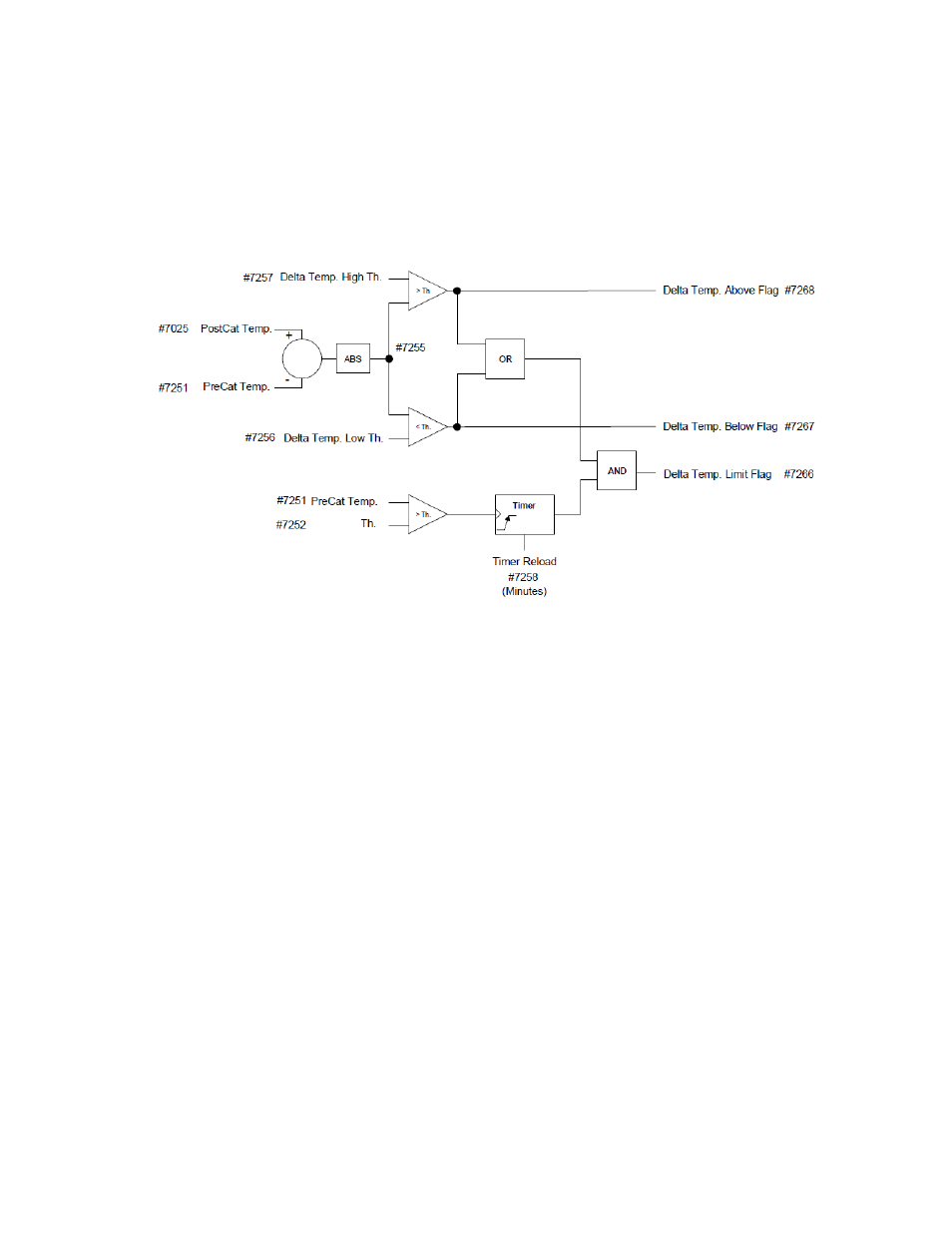

15. Catalytic Converter Delta Temperature

The logic diagram below shows the operation of the catalytic converter differential

temperature measurement function. The pre-cat temperature is subtracted from the

post-cat temperature to obtain delta temperature. The "Filter Time" set on the Post-

Cat Cfg screen is then applied to the delta temperature used for the trips. A trip will

occur if either the Delta Temp High or Delta Temp Low thresholds are exceeded,

provided the start timer shown at the bottom of the diagram has expired.

16. Data Logging

The AF900PC has powerful data logging capabilities through the use of on-board

Flash Memory, providing up to 64 Megabytes of capacity.

Up to 15 parameters can be logged as fast as every 1 second. Additionally,

ALARMS can be chosen for data logging as well as the AF900PC status

(MANUAL, START, AUTO, AUTO).

Using Dynalco’s Windows-based DynaTrend software, the user can transfer the

logged data to a laptop and view or graph the data. Dynalco’s DynaTrend software

can automatically and seamlessly open Excel to view and graph the data. Each

parameter logged is identified with a label and also a time/date stamp. Once the

data has been transferred to a laptop using DynaTrend, the file can be saved and

assigned a file name that can be the engine name/number/date, etc. with Windows

standard long filenames.

AF900PC

Catalytic Delta Temperature