Wiring the af900pc controller, Electrical connections – Dynalco AF-900PC Air/Fuel Ratio Controller User Manual

Page 10

9

6.5 Installation of the full-authority fuel valves (one per bank)

The full-authority fuel valves are to be mounted between the fuel regulator and

carburetor fuel inlet, as close to the carburetor inlet as possible.

7. Wiring the AF900PC Controller

All wiring to the AF900PC enters the controller through three (3) conduit openings

in the bottom and connects to three (3) double row terminal strips on the bottom of

the controller main board. The terminal strips unplug from the main board for ease

of controller wiring and replacement. The main board cover plate shows the

location of the terminal strips.

Wiring for terminal strip TS1 should enter through the left conduit opening.

Wiring for terminal strip TS2 should enter through the center conduit opening.

Wiring for terminal strip TS3 should enter through the right conduit opening. This

will separate the millivolt signal levels on TS1 and TS2 from the power, output, and

relay wiring on TS3.

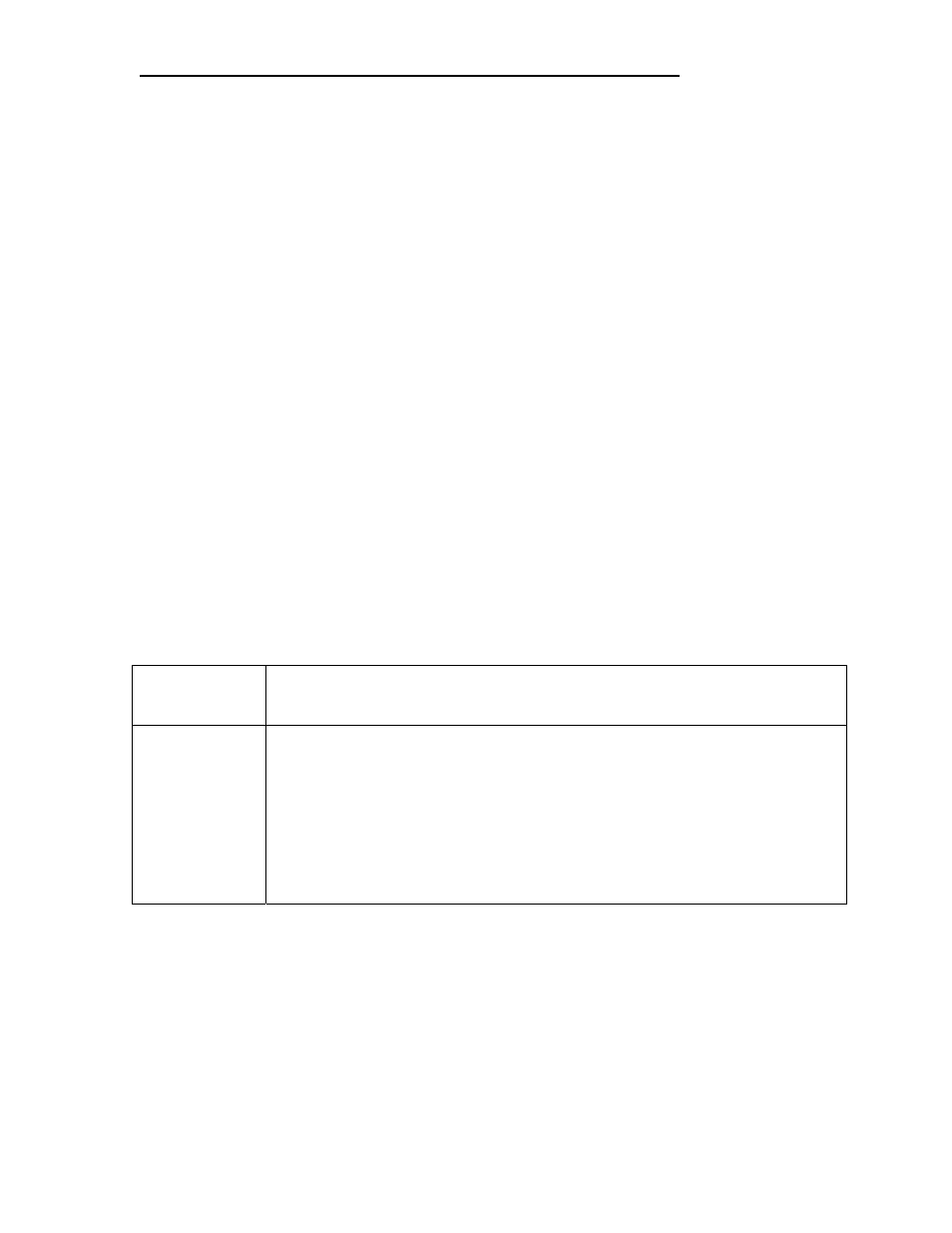

8. Electrical Connections

The Fuel Valves must be configured for single demand, PWM control, and low side

drive.

Terminal Strip

TS1

Bottom Row

Description

TS1-1

TS1-2

TS1-3

TS1-4

TS1-5

TS1-6

TS1-7

TS1-8

TS1-9

Left Bank Oxygen Sensor Output +

Left O2 Sensor Cable - (Black and Shield)

Right Bank Oxygen Sensor Output +

Right O2 Sensor Cable - (Black and Shield) (DB only)

Post-Catalyst Sensor Cable + (White)

Post-Catalyst Sensor Cable – [Black (paired with white) and shield]

Speed Contact Closure + (Required if speed magnetic pickup is not used)

Speed Magnetic Pickup +

Speed Magnetic Pickup - and shield (for speed contact closure if used)