ADS Environmental Services Model 3600 530002 A2 User Manual

Page 9

1-4

ADS 3600 Flow Monitor O&M Manual

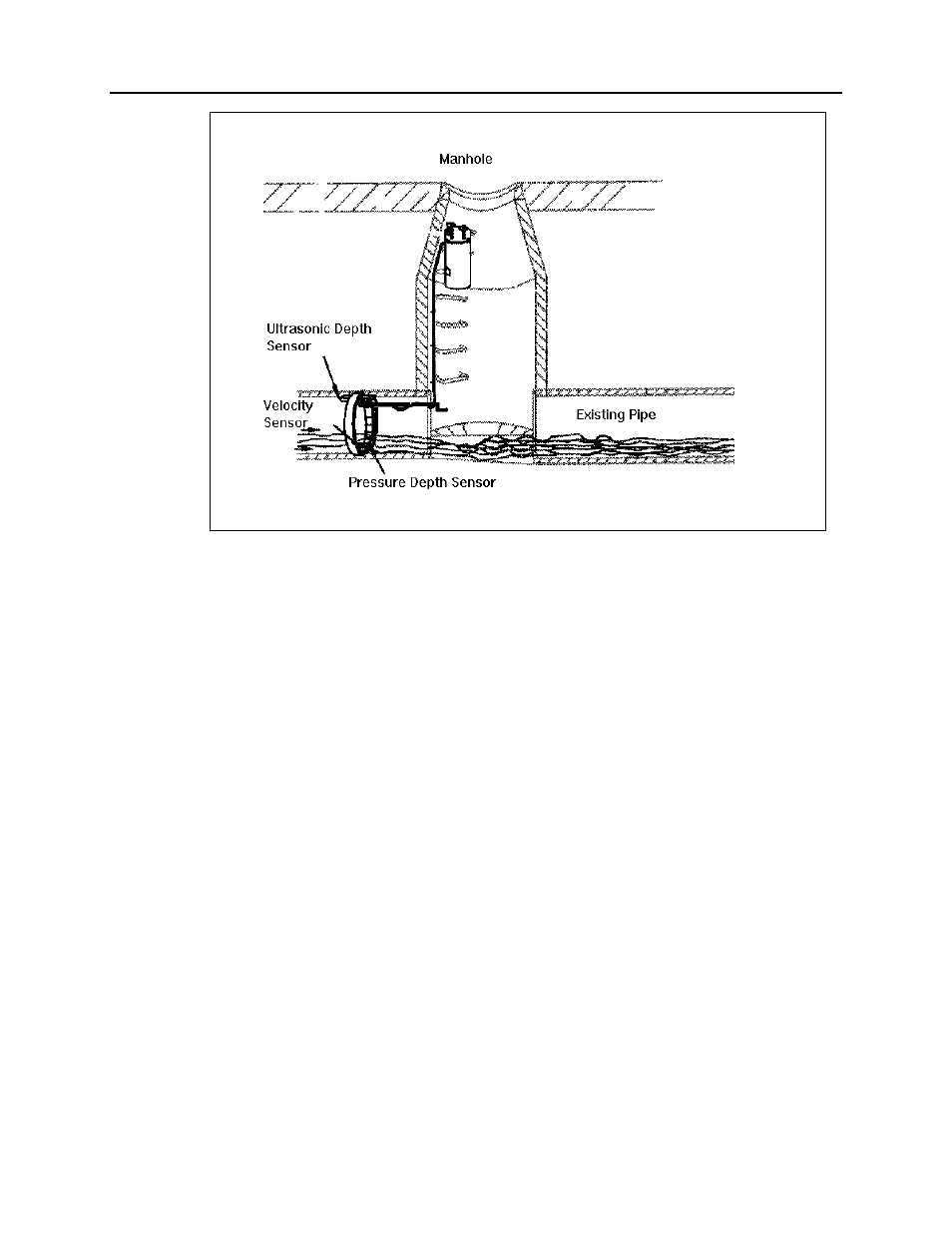

Typical 3600 Flow Monitor Installation

Typically, the monitor is attached to the inside wall of a manhole using bolts. Depth

and velocity flow sensors are installed in the sewer pipe to gather flow data. The

sensors are mounted on a stainless steel ring, usually placed upstream in the sewer

pipe. Cables connect the monitor in the manhole to the sensors in the sewer pipe. The

QS3600 flow monitor is linked to a central IBM-compatible personal computer with a

voice-grade telephone line and either an IS modem or an external modem unit

(EMU). (Data can also be acquired serially directly from the monitor with an

internal IS modem). This link allows you to communicate with the monitor,

configure the monitor, activate the monitor, collect data, and perform monitor

diagnostics from a remote location.

In order to measure the flow rate in a sewer pipe, the QS3600 flow monitor gathers

data on the depth and/or velocity of the flow. The monitor gets this data by

periodically scanning the sensors which are installed in the pipe. The monitor uses

two types of sensors to determine the depth of flow: the ultrasonic depth sensor and

the pressure depth sensor. The monitor has a Doppler velocity sensor to measure

flow velocity. See Chapter 2 for information on the monitor’s key hardware

components. See Chapter 3 for a more detailed explanation of monitor operation.