147a hose diagram – Great Plains PTO Kits 2-3-Section User Manual

Page 86

82

2- & 3-Section YP PTO Pumps

Great Plains Manufacturing, Inc.

411-015M

2014-09-10

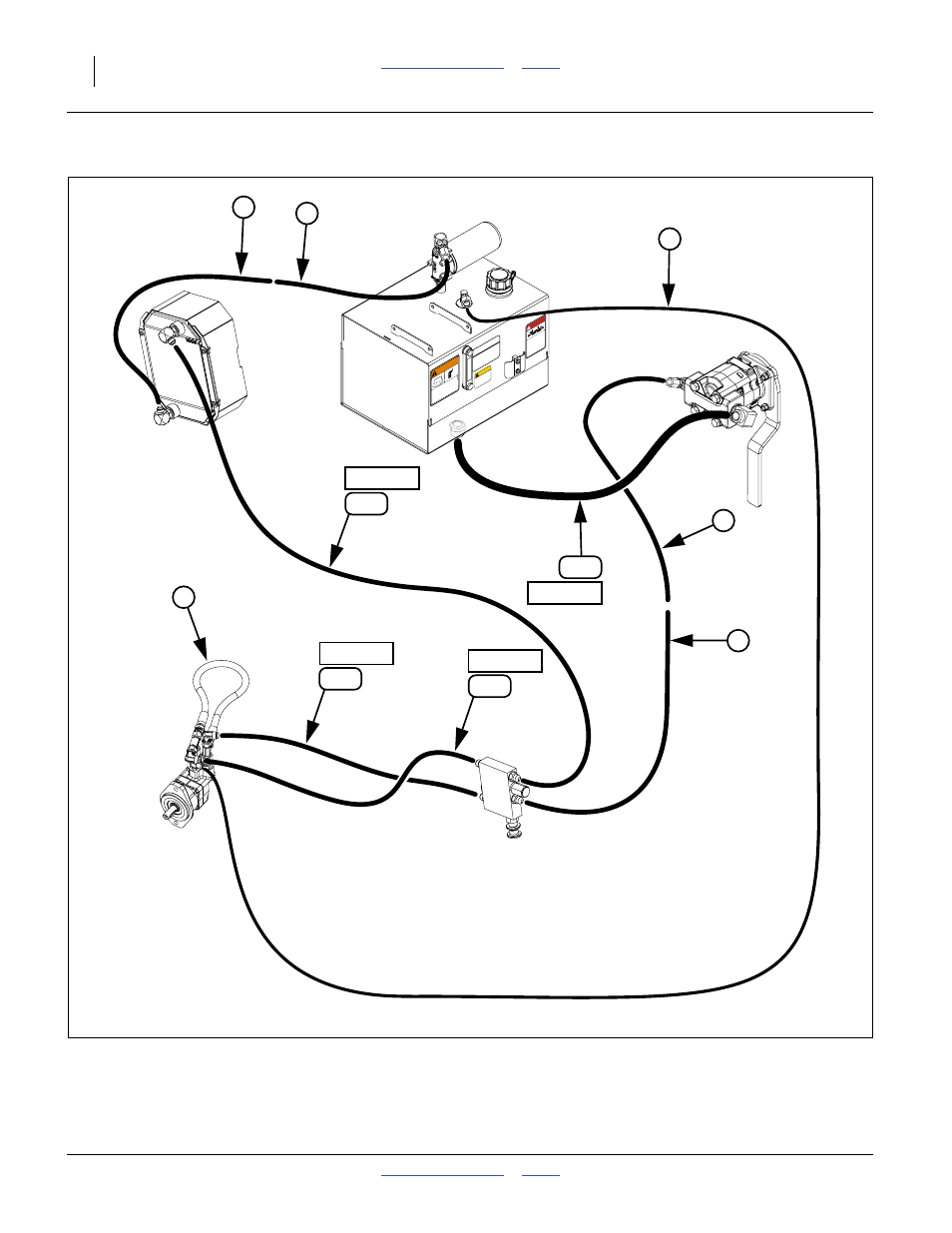

411-147A Hose Diagram

Figure 78: PTO Kit 411-147A Hose Routing

YP1625AHD

36375

M

T T

P

818-240C Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

858-

004C

Read Owner’

s Man

ual BEFORE oper

ating machine

.

Keep tr

actor at IDLING SPEED and slo

wly engage PT

O

to pre

vent damage to Hydr

aulic Motor

Keep Radiator clean and free of f

orei

gn matter

to

pre

vent o

verheating.

Do NO

T oper

ate with h

ydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

858-00

5C

All dr

iveline guards

, tr

actor

and

equipment shields in place

PT

O pump a

ssemb

ly securel

y

attached with torque ar

m and chain

RO

TA

TING DRIVELINE -

CONT

AC

T CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DA

NG

ER

858

-0

29

C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BASED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF

10W

-30.

OIL MUST BE CLEAN AND FREE

FR

OM DIR

T OR CONT

AMINAN

T P

AR

TICLES

TO

PREVENT D

AMA

GE

TO PUMP AND MO

TOR

.

REPLA

CE

FIL

TE

R ELEME

NT

AFTER EVER

Y

150 OPERA

TING HOURS OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL LEVEL

OIL FILL LINE

A

B

C

L

E

D

282

298

296

851-347C

851-345C

841-920C

298

851-347C

Fan