Lubrication and scheduled maintenance, Oil filter, Pump/fan oil – Great Plains PTO Kits 2-3-Section User Manual

Page 27: Seal kit, 300 or 4 years, As needed

Great Plains Manufacturing, Inc.

PTO Maintenance

23

2014-09-10

411-015M

Lubrication and Scheduled Maintenance

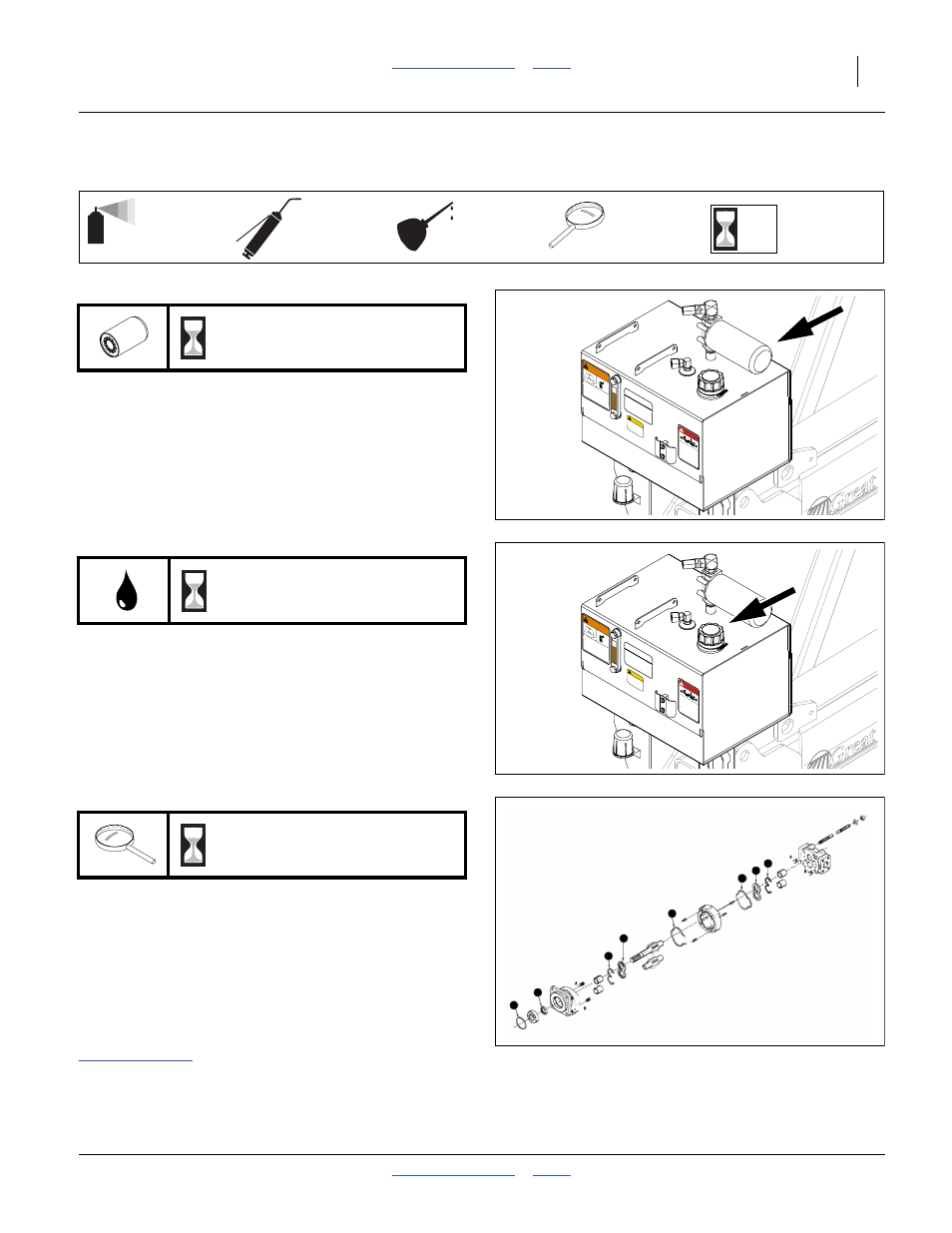

Oil Filter

1 filter per planter

Change filter after first 25 hours, and then every 2 years

or 150 hours.

Pump/Fan Oil

1 reservoir per planter

Change filter when changing oil, except at initial system

flush.

Seal Kit

1 kit per planter, includes snap ring and all seals

Consult the

Service Manual

PGP/PGM315, 330, 350, 365

HY09-SM300/US,

available from Parker Hannifin Corporation:

25 / 150

Type:

Great Plains 891-385C

Fleetguard HF6611

Zinga HE-10L

50

Multi-purpose

spray lubricant

Multi-purpose

grease lubricant

Multi-purpose

oil lubricant

Intervals

(operating hours)

at which service

is required

Inspection

34208

85

8-0

30C

All dr

ive

lin

e

gu

ar

ds,

tractor

and equipment shields in place

PT

O pump

assemb

ly securely

attached with torque ar

m and clamp

bo

lts pro

per

ly to

rqued

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DA

NGE

R

858-

029C

CAP

ACITY = 13.5 U

.S

. GA

LS

USE A

NY HIGH

QU

AL

ITY

MINE

RA

L BA

SE

D

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 1

0W-

30

. OIL

MU

ST

BE

CLEA

N A

ND

FREE

FRO

M

D

IR

T O

R

CO

NT

AMIN

AN

T

PA

RT

ICL

ES T

O

PR

EVENT D

AMA

GE

TO PUMP AND M

OTO

R.

REPLA

CE

FIL

TER ELEMENT

AFTER EVER

Y

150 OP

ERA

TING

HOU

RS

OR 2

Y

EA

RS

S

ER

VI

CE

.

LE

VE

L T

OO

LBA

R BEF

OR

E C

HEK

IN

G

OIL L

EVEL

OIL FILL LINE

858-

004

C

Read O

wne

r’s Ma

nual B

EFORE oper

ating ma

chine

.

Keep tr

ac

tor at I

DLIN

G

SPEED a

nd

slo

wly e

nga

ge

PTO

to pre

vent damage t

o Hydr

aulic

Motor

Ke

ep Radiat

or clean and fr

ee of f

oreign matter to

pre

ven

t ov

erh

ea

ting

.

Do N

OT op

erate

w

ith h

ydr

auli

c oil at

or a

bov

e 180

°F.

HO

T FLUID HAZARD

WARNING

818-

240

C

Rev

. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

34843

300 or 4 Years

Type:

10W-30 Mineral-Based Oil

70 to 250 SUS at 210

°F (100°C)

Quantity: 13.5 U.S. gallons (51 liters)

858-

030C

All dr

iveline guards

, tr

actor

and equipment shields in place

PT

O pump assemb

ly securely

attached with to

rque

ar

m and clamp

bolts proper

ly torqued

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DA

NGE

R

85

8-02

9C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BASED

HYDRA

ULIC FLUID

W

IT

H A

VISCOSITY RA

TI

NG

OF 10W

-30.

OIL MUST BE CLEAN AND FREE

FR

OM

DIR

T OR CONT

AMINANT P

AR

TICLES

TO

PREVENT D

AMA

GE

TO PUM

P AND

M

OTO

R.

REPLA

CE FIL

TER ELEMENT AFTER EVER

Y

150 OPERA

TING HOURS OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL LEVEL

OIL FILL LINE

858-004C

Read Owner

’s Ma

nual BEFORE oper

ating mach

ine.

Keep tr

actor at IDLING

SPEED and slo

wly engage PT

O

to pre

vent d

amage to Hydr

aulic Motor

Keep Radiat

or clean and free of f

oreign matter to

pre

vent o

verheating.

Do

NO

T oper

ate with

hydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

818-240C Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

34843

As Needed

Type:

810-901C for Parker 350C pumps

810-902C for Parker 365C pumps

34852