Adjustment steps, Flow adjust: hydraulic drive intelliag, Singulator plus™ & finger pick-up planters – Great Plains PTO Kits 2-3-Section User Manual

Page 22

18

2- & 3-Section YP PTO Pumps

Great Plains Manufacturing, Inc.

411-015M

2014-09-10

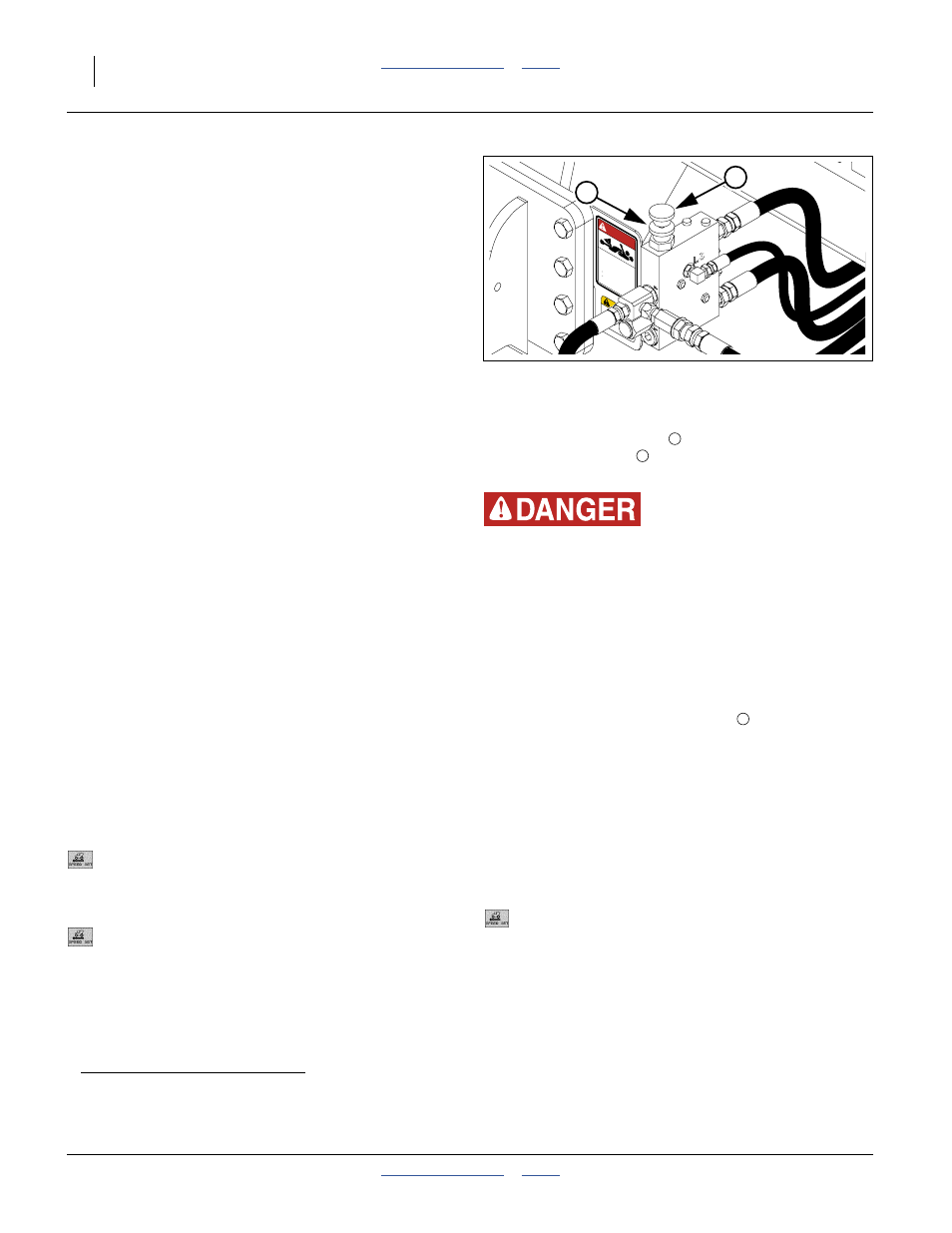

Flow Adjust: Hydraulic Drive IntelliAg

®

Singulator Plus™ & Finger Pick-Up Planters

On hydraulic drive models YP1225#56, YP1625#56,

YP2425, YP2425F, YP3010HDP, YP3020P, YP3025,

YP4010HDP, YP4020P, YP4025, YP4025F and

3PYP#56, the PTO system drives two

a

or three motors,

plumbed in parallel:

a.

One fan motor (two on model YP2425F) generates

an airflow for seed delivery and/or fertilizer delivery

(models YP2425F, YP4025F).

b.

The other motor, for seed meter operation, is under

seed monitor control, via a proportional flow solenoid

valve.

When engaged at typical field seed rates, the seed drive

motor reduces flow to the delivery fan. The seed motor

needs to be engaged at least briefly during setup to

choose a flow rate that keeps the delivery fan at optimal

speed.

Adjustment Steps:

1.

Have the DICKEY-john

®

Planter/Drill Control User

Level 2&3 manual at hand. Making changes to the

GROUND SPEED SETUP configuration requires

the Level 2 password.

2.

Have the Operator and Seed Rate manuals at hand,

so that the fan rpm target is known for the seed to

be planted.

3.

Loading seed is not required. Loading fertilizer is

not recommended. If you do load seed, set out

recovery means to capture seed metered during

testing, or use section clutches

b

to disable

metering.

4.

Turn the IntelliAg

®

monitor system on.

Turn the Master switch off.

On the console, navigate to the

GROUND SPEED SETUP screen.

Record the ground speed constant:

5.

Set:

6.

Hitch the tractor to be used, and install the PTO

pump. Raise the planter. Unfold the planter.

Release the lock disc

counter-clockwise to

release the knob

. Turn the knob fully clockwise to

shut off flow to the motors.

Entanglement and Crushing Hazard:

Use extreme caution in the hitch area when the PTO is

operating.

8.

Start the tractor, and seed monitor. Bring the PTO

up to expected field rpm (which is often not the full

1000 rpm).

9.

Turn the IntelliAg

®

Master switch on to engage the

hydraulic seed meter drive.

10. With one person observing the fan rpm readout on

the seed monitor, turn the knob

counter-clockwise until the fan is at the rpm

recommended for this planter configuration, crop,

population and intended field speed.

Secure the knob at this setting with the lock disc.

11. Shut down the PTO. Set Master switch off.

12. On the console, navigate to the

GROUND SPEED SETUP screen.

Restore the original settings:

Monitor fan rpm when planting. If it is lower than during

flow setup, perform the setup steps again, and set the

valve for a higher rpm.

a. If the Yield-Pro

®

PTO pump system was ordered for ground drive, the hydraulic drive is still on a dedicated circuit. In this case, load

seed, but ignore the steps to compensate for seed drive motor load.

Figure 14:

Flow Control Valve (3PYP#56)

34848

818-240C Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

85

8-

030C

All dr

iveline guards

, tr

actor

and equipment shields in p

lace

PT

O pump assemb

ly securely

attached with torque ar

m and clamp

bolts proper

ly torqued

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DANGER

b. If Swath Command™ section control is installed, connect the compressor at the hitch, or clutches will not disengage.

Source

Gspd Constant

Digital Freq.

12345

(actual value varies)

Source

Manual Gnd Spd

Implement Lift

Manual

5.0 MPH

(or as desired)

Disabled

Source

Gspd Constant

Implement Lift

Digital Freq.

12345

(actual value varies)

Enabled

1

2