Pto maintenance, Oil and filter change, Oil fill – Great Plains PTO Kits 2-3-Section User Manual

Page 26: Oil specification, Pto maintenance oil and filter change

411-015M

2014-09-10

22

2- & 3-Section YP PTO Pumps

Great Plains Manufacturing, Inc.

PTO Maintenance

Oil and Filter Change

Oil Fill

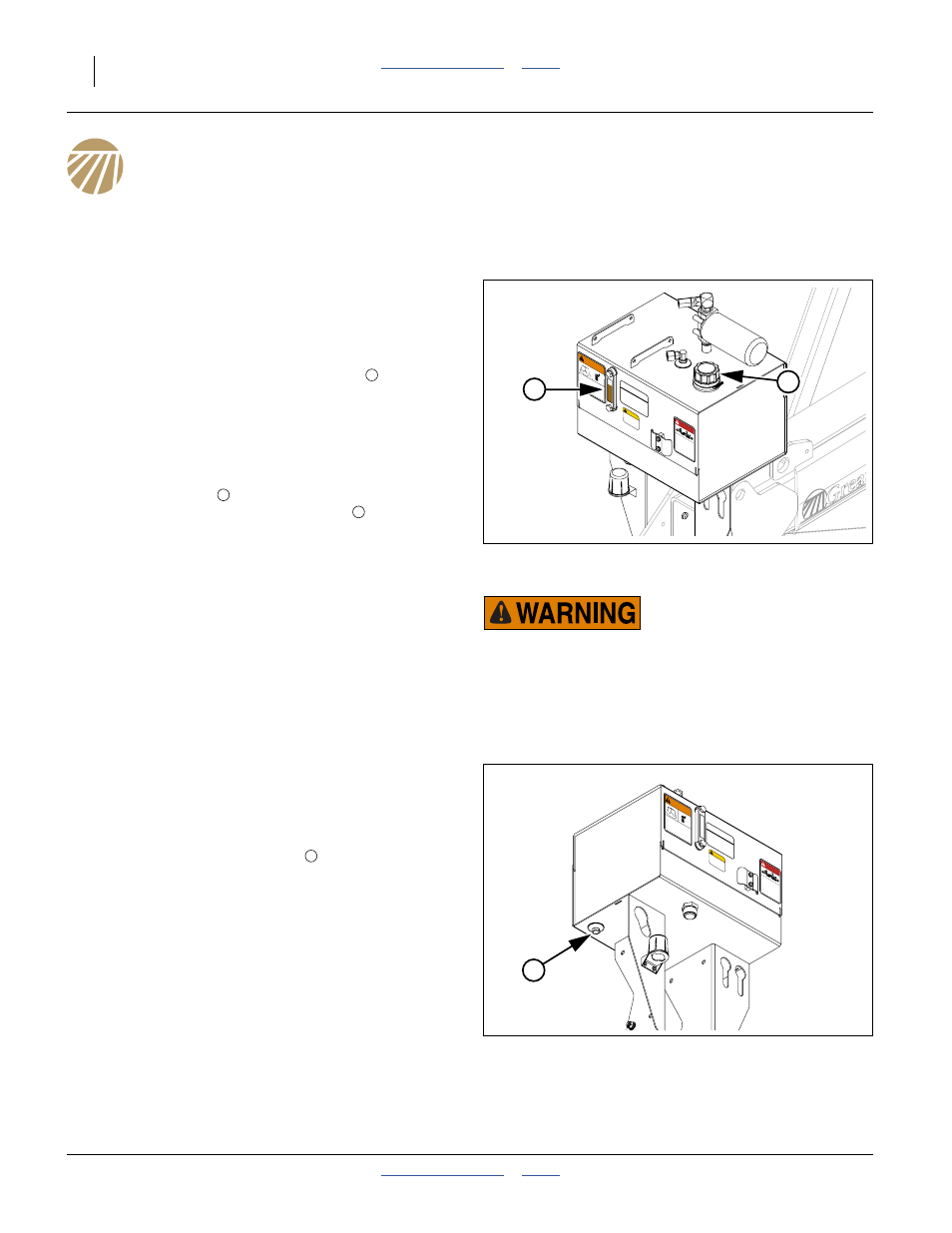

Refer to Figure 17 and Figure 18

A dry or fully drained system may require as much as

20 gallons (76 liters) of oil to charge the cooler, pump,

motor(s), hoses, filter and valve, and leave 13.5 gallons

(51 liters) in the reservoir.

Before adding oil, check that the drain plug

is secure,

and that there are no signs of leaks in hoses or at any

system fittings.

Oil Specification

10W-30 good quality mineral base hydraulic fluid,

viscosity 70 to 250 SUS at 210

°F (100°C)

Remove the filler cap

. Add oil until the oil level in the

reservoir, as observed on the sight gauge

, reaches the

fill line on the decal (the top edge of the horizontal

mid-border of the decal). The fill line is 10.73 inches

(27.3 cm) above the reservoir bottom. If the 858-029C

decal requires replacement, adjust the center border line

to this height.

Operate the PTO system briefly, or until the reservoir

level stops changing. See “PTO Operation” on page 8

for operations.

Recheck the sight gauge. As necessary, add oil to fill

line.

Oil and Filter Change

At a regularly scheduled oil change, also change the

filter. At initial system flush, no filter change is required.

Refer to Figure 18 and Figure 17

1.

Wait for the oil to cool before changing the oil.

2.

Place a container with at least a 20 gallon (76 liter)

capacity under the drain plug

of the reservoir.

3.

Carefully remove the drain plug.

4.

Allow several minutes for oil in the filter to drain into

and out of the reservoir. Change filter as required.

See page 23 for filter size. Seat filter per

instructions on filter.

5.

Thread the plug back into the reservoir. Seating

torque is 27 to 43 foot-pounds (37 to 58 N-m).

85

8-

030

C

Al

l dr

ive

line

gua

rds

, tr

ac

tor

an

d e

quipmen

t s

hields in

plac

e

PT

O pump

assemb

ly s

ec

ure

ly

attached with torque ar

m and clamp

bolts proper

ly torqued

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DA

NGE

R

85

8-0

29C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIG

H QU

ALITY

M

INE

RA

L B

ASED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 1

0W-

30

. O

IL

MUS

T B

E

CL

EA

N AND

FR

EE

FR

OM DIR

T OR

C

ON

TA

M

INANT

PA

RT

IC

LE

S

TO

PREVENT D

AMA

GE

TO PUMP AND

MO

TOR

.

REPLA

CE FIL

TER

ELEMEN

T AFTER

EVER

Y

15

0 OPERA

TING HOU

RS OR 2

YE

AR

S SER

VIC

E.

LEVE

L T

OOL

BAR

B

EFO

RE

CHEKI

NG

OIL L

EVE

L

OIL FILL LINE

858-0

04C

Re

ad Ow

ner’

s M

anu

al BEF

ORE

ope

rating

m

ac

hine

.

Keep

tra

ctor a

t IDL

IN

G SPEED

and

slo

wly

en

gage

PT

O

to

pre

vent da

ma

ge to

Hy

drauli

c M

otor

Ke

ep R

adiator clea

n and f

ree

of fo

reig

n m

atter to

pre

vent o

verheating.

Do NO

T o

pe

rate w

ith

hydr

aulic o

il at or abo

ve 1

80°F

.

HO

T FLUID HAZARD

WARNING

818-2

40C R

ev. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

2

3

Hot Surface and Hot Fluid Hazards:

Assess the reservoir temperature before adjusting oil level.

Draining excess hot oil could result in a severe burn. If the

PTO has been operated recently, the oil temperature could be

as high as 180

°F (82°C).

Figure 17:

Oil Filler Cap and Filter

34843

1

Figure 18:

Oil Drain Plug

34850

858-03

0C

All

dr

iveline guards

, tr

actor

and e

quipment

shields in place

PT

O pump assemb

ly securely

attached with torque ar

m and clamp

bolts pro

per

ly torque

d

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY

!

DO NO

T OPERA

TE

WITHOUT

-

DANGER

85

8-029C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BA

SED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 10W

-30.

OIL MUST BE CLEAN AND FRE

E

FR

OM DIR

T OR CONT

AMIN

ANT P

AR

TICLES

TO

PREVENT D

AMA

GE

TO PUMP AND MO

TOR.

REPLA

CE FIL

TER ELEMENT AFTER EVER

Y

150 OPERA

TING HOURS OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL

LEVE

L

OIL FILL LINE

858-004C

Read Owner’

s Ma

nual BEFORE oper

ating machine

.

Keep tr

actor at IDLING SPEED and slo

wly engage PT

O

to pre

vent damage to Hy

draulic Motor

Keep Radiator clean and free of f

oreign matter to

pre

vent o

verheating.

Do NO

T oper

ate with h

ydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

818-240C

Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

1

1