934a hose diagram – Great Plains PTO Kits 2-3-Section User Manual

Page 54

50

2- & 3-Section YP PTO Pumps

Great Plains Manufacturing, Inc.

411-015M

2014-09-10

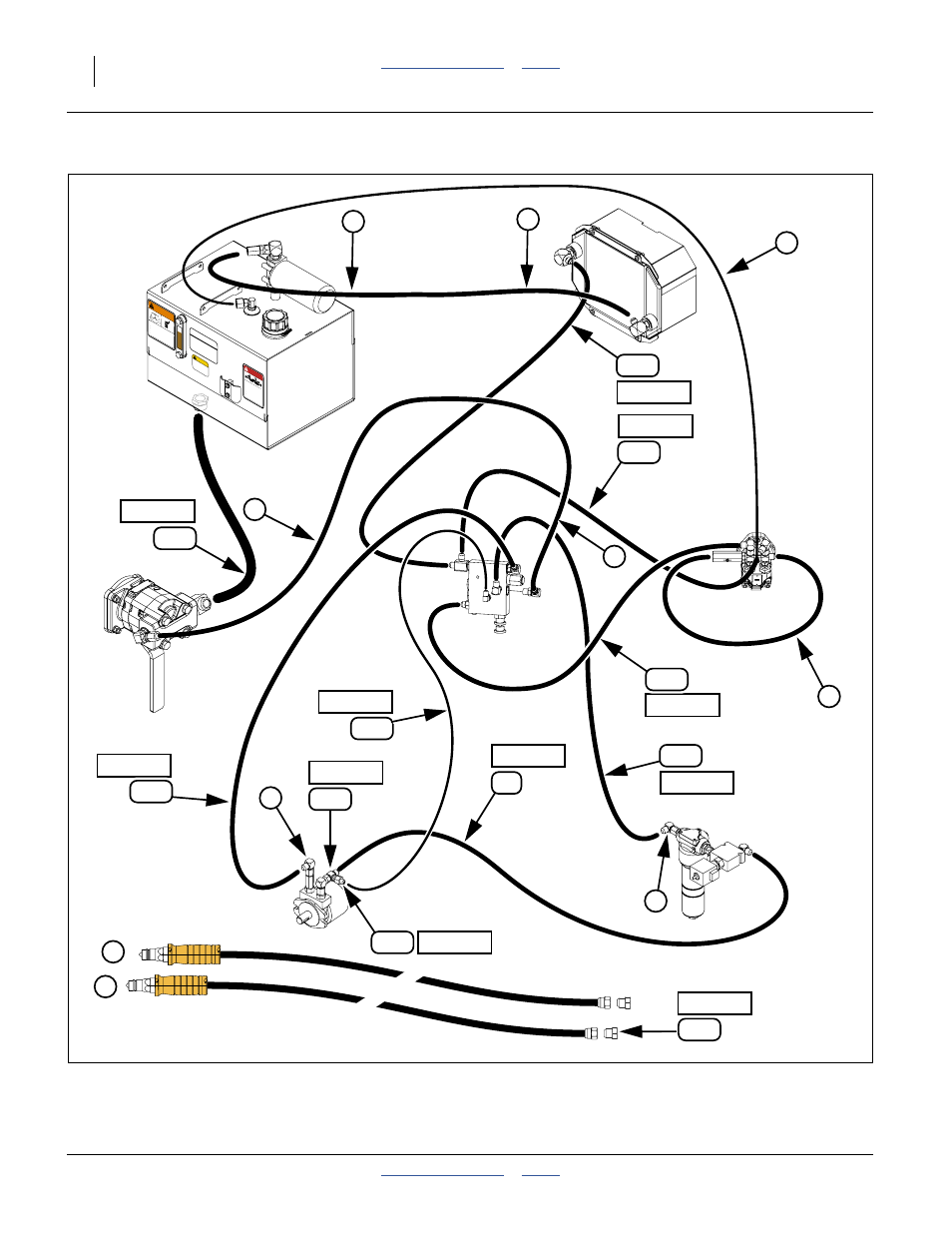

401-934A Hose Diagram

85

8-03

0C

All dr

iveline guards

, tr

actor

and

equipment sh

iel

ds in

place

PT

O pump assemb

ly secure

ly

attach

ed w

ith to

rque ar

m and clam

p

bo

lts

p

rop

erl

y

to

rqu

ed

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DANGER

858-

029C

CAP

ACITY = 13.5 U

.S

. G

AL

S

USE

ANY HIGH Q

UALITY

MINERAL

BASED

HYDR

AULIC FLUID

WITH A

VIS

COSITY

RA

TING

OF 10W

-30.

OIL MUST BE CLEAN

AN

D FREE

FR

OM DIR

T OR CONT

AMINANT P

AR

TICLES

TO

PR

EVENT D

AMA

GE

TO PUMP AND

M

OTO

R.

REPLA

CE F

ILTER ELE

MENT

AFTER EVER

Y

150 OPERA

TING H

OURS OR 2

YE

AR

S SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OI

L LEVEL

OIL FILL LINE

858-

004

C

Read O

wner’

s Man

ual BEFORE oper

ating mac

hine

.

Keep tr

actor at IDLIN

G SPEED a

nd slo

wly eng

age PT

O

to pre

vent damage

to

Hydr

aulic

Motor

Keep Radiato

r clean and free of f

oreign matter to

pre

vent

ov

erh

eating.

Do NO

T oper

ate with h

ydr

aulic

oil a

t or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

81

8-24

0C

Rev

. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

LS

P P

T

M

T

Figure 62: PTO Kit 401-934A Hose Routing

YP1225, YP1625 Finger-Pickup or Singulator Plus™ Hydraulic Drive

36341

G

C

L

A

D

811-341C

247

46

811-073C

811-146C

234

230

811-780C

252

811-780C

252

841-389C

269

841-920C

282

841-196C

263

841-517C

273

841-517C

273

811-331C

2

1

E

B

Fan

Hydraulic Drive