Reinstall compressor(s), Install first or only compressor, Kit kit description go to – Great Plains PTO Kits 2-3-Section User Manual

Page 45

Great Plains Manufacturing, Inc.

Appendix A - Installation

41

2014-09-10

411-015M

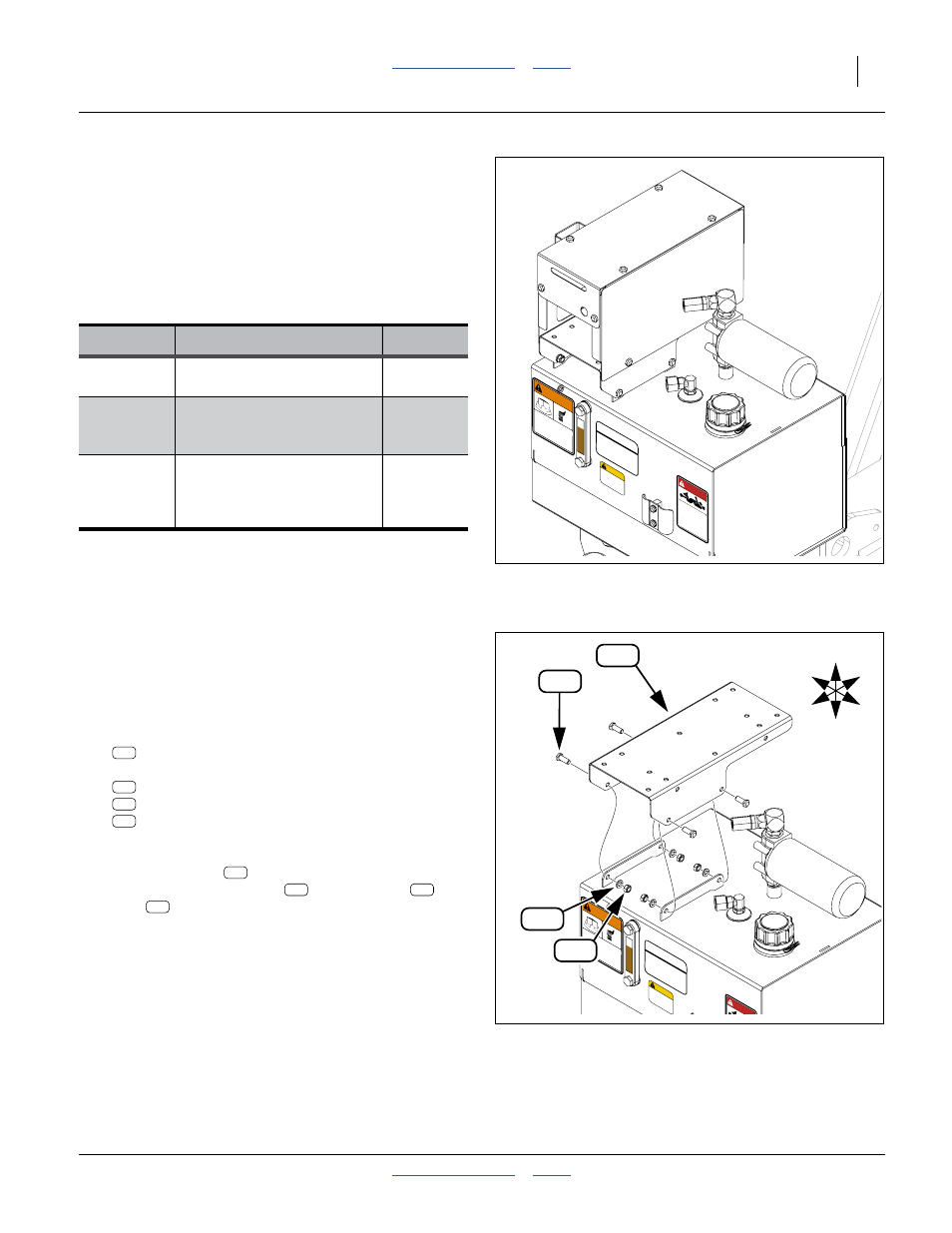

Reinstall Compressor(s)

This topic applies only to pull-type planters with tongue-

mounted compressors used for Row-Pro™ or Swath

Command™. The compressor(s) were removed at

“Dismount Air Compressor(s)” on page 29. If no

compressors were dismounted, continue at “Install Flow

Control Valve” on page 43.

Compressor Install Page

Install First or Only Compressor

This applies to compressor relocation kit:

411-183A PTO AIR COMP MNT ASSEMBLY

For other kits, see the page director table on page 41.

Refer to Figure 49

74. Select one new:

421-173D PTO TANK AIR COMP MNT PLT

and four sets new:

802-017C HHCS 3/8-16X1 GR5

804-013C WASHER LOCK SPRING 3/8 PLT

803-014C NUT HEX 3/8-16 PLT

With the mounting holes to reservoir front, secure

the mount plate

reservoir, using the bolts

, lock washers

and

nuts

.

75. (not shown) Reinstall the compressor and its

housing, using the saved fasteners.

Continue at “Install Flow Control Valve” on page 43.

Kit

Kit Description

Go To

First or only compressor, on

Reservoir top, all models

Second compressor, models:

1625AHD/L, YP1220,

YP1225/A, YP1625/A

Second compressor, models:

YP2425/A/F, YP3010HDP,

YP3025/A, YP4010HDP,

YP4025/A/F

858-030C

All dr

iveline guards

, tr

actor

and equipment shields in place

PT

O pump assemb

ly securely

attached with torque ar

m and clamp

bolts proper

ly torqued

RO

TATING DRIVELINE -

CONT

ACT CAN CA

USE DEA

TH

KEEP A

W

AY!

DO NO

T OPERA

TE

WITHOUT

-

DANGER

858-029

C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BASED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 10W

-30.

OIL MUST BE CLEAN AND FREE

FR

OM DIR

T OR CONT

AMINANT P

AR

TICLES

TO

PREVENT D

AMA

GE

TO PUMP AND MO

TOR.

REPLA

CE FIL

TER ELEMENT AFTER EVER

Y

150 OPERA

TING HOURS OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL LEVEL

OIL FILL LINE

858-004

C

Read Owner’

s Man

ual BEFORE oper

atin

g machine

.

Keep tr

ac

tor at IDLING SPEED and slo

wly engage PT

O

to pre

vent damage to

Hydr

aulic Motor

Keep Radiator clean and free of f

oreign matter to

pre

vent o

verheating.

Do NO

T oper

ate with h

ydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

818-2

40

C Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

Figure 48:

Compressor Re-installed

36387

DA

NGER

858-029C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BASED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 10W

-30.

OIL MUST BE CLEAN AND FREE

FR

OM DIR

T OR CONT

AMINANT P

AR

TICLES

TO

PREVENT D

AMA

GE

TO PUMP AND MO

TOR.

REPLA

CE FIL

TER ELEMENT AFTER EVER

Y

150 OPERA

TING HOURS OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL LEVEL

OIL FILL LINE

858-004C

Read Owner’

s Man

ual BEFORE oper

ating machine

.

Keep tr

actor at IDLING SPEED and slo

wly engage PT

O

to pre

vent damage to Hydr

aulic Motor

Keep Radiator clean and free of f

oreign matter to

pre

vent o

verheating.

Do NO

T oper

ate with h

ydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

818-240C Re

v. A

To a

void Injur

y or

Mac

hine Dama

ge:

·Operate onl

y with

1000 rpm PT

O

CAUTION

195

214

208

U

D

F

B

L

R

Figure 49:

36386

195

214

208

195

214

208