Dismount air compressor(s) – Great Plains PTO Kits 2-3-Section User Manual

Page 33

Great Plains Manufacturing, Inc.

Appendix A - Installation

29

2014-09-10

411-015M

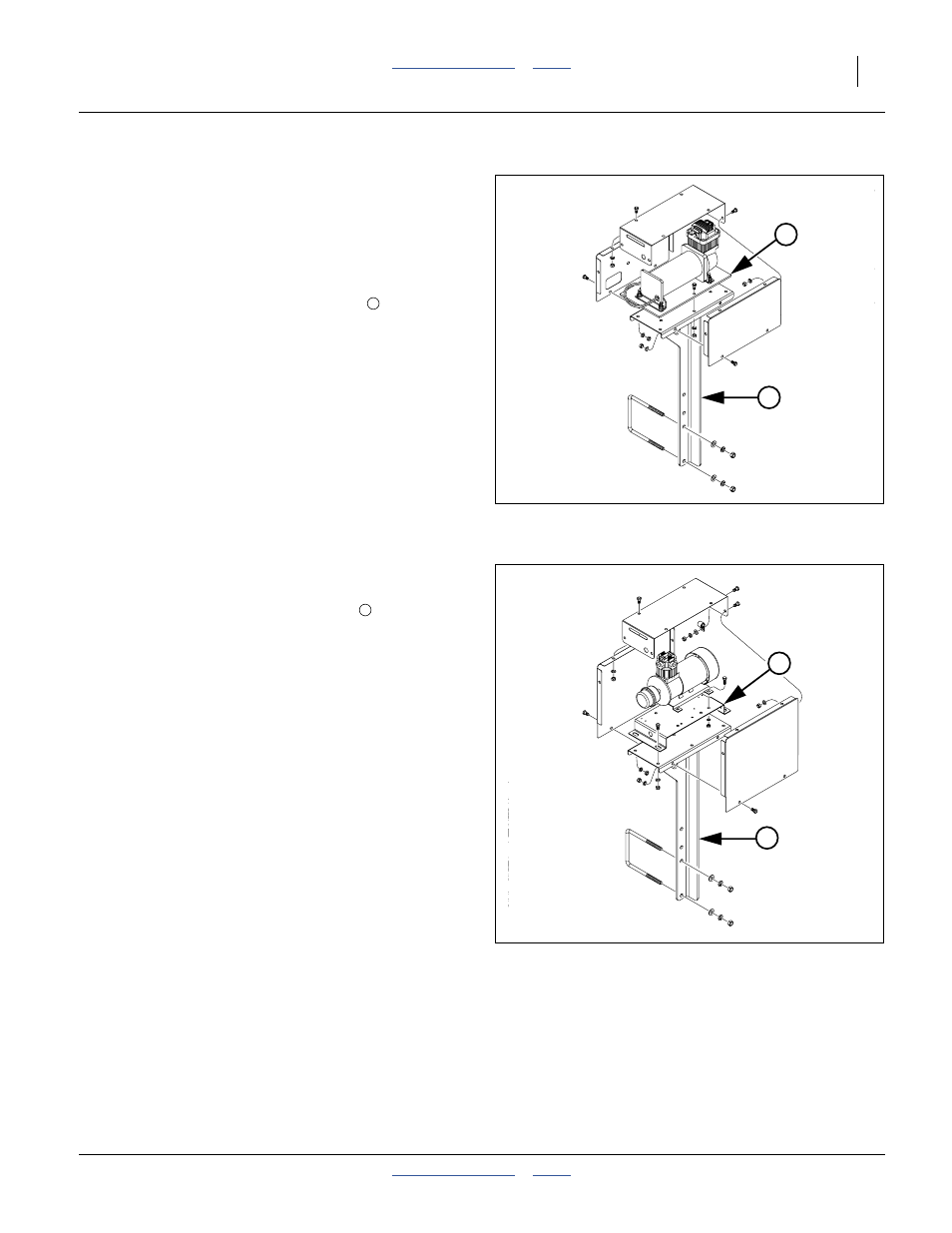

Dismount Air Compressor(s)

For models 3PYP and 3PYPA, continue at “Prepare

Fan(s)” on page 31.

For pull-type planters having no compressors, continue

at “Prepare Fan(s)” on page 31.

Refer to Figure 23 and Figure 24

Any air compressors at the tongue of a pull-type are

presently installed on their own pedestals

interfere with a PTO reservoir installation. The pedestals

are removed, and the compressors relocated to mounts

on the reservoir.

The needed reservoir mounts are separately purchased.

See page 6 for ordering information.

19. Remove protective housings at each compressor.

Save all parts and fasteners.

20. Locate a suitable disconnection point for each air

and electrical line near each compressor.

21. Label each tractor-side or implement-side hose or

lead as to which compressor it serves.

22. Disconnect the lines. Tape the air hoses or tie them

off to prevent ground contact or contamination.

23. Dismount each compressor assembly by removing

the fasteners that connect the base

pedestal platform. Save the assembly and all

fasteners.

24. At each lower U-bolt, dismount the pedestal from

the tongue. The pedestal, U-bolt, U-bolt washers

and U-bolt nuts are not re-used.

Each compressor is re-installed on a new mount at a

later step.

2

1

Figure 23:

Row-Pro™ Compressor

34090

1

Figure 24:

Swath Command™ Compressor

34090

2