Pto troubleshooting – Great Plains PTO Kits 2-3-Section User Manual

Page 25

2014-09-10

411-015M

Great Plains Manufacturing, Inc.

21

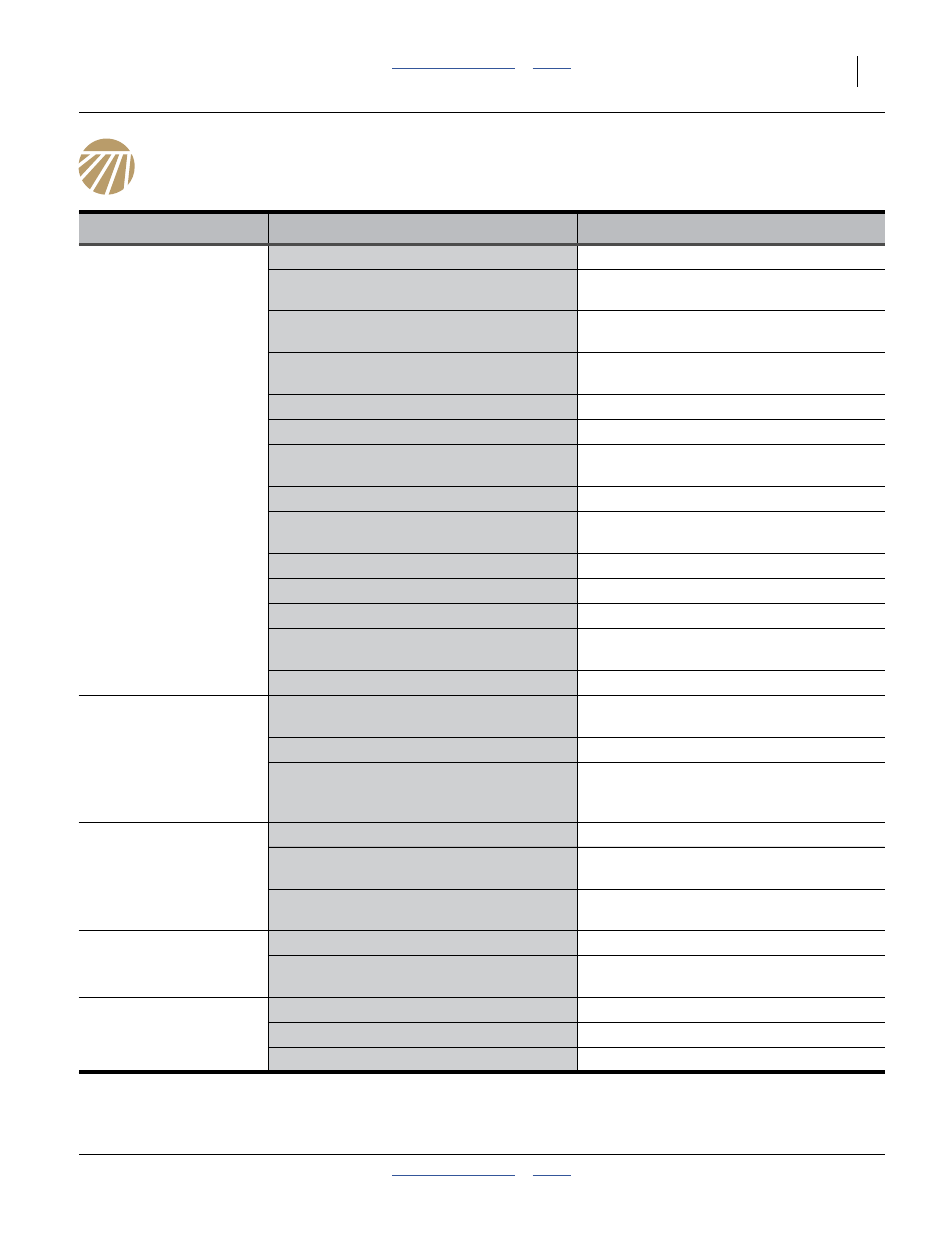

PTO Troubleshooting

Symptom

Cause

Remedy

Air-Pro

®

seed meter

pressure too low

Flow control adjusted too low

Increase flow control (page 13).

Fan butterfly valve closed or set at too high

an angle

Adjust angle (see Operator manual).

PTO rpm too low

Bring up PTO rpm, but do not exceed

1000 rpm.

Fan running in reverse (multiple possible

causes)

See “Fan running in reverse” below.

Pump cavitating

Check oil level (page 11).

No blank disks in unused seed meters

Install blank disks to balance pressure.

Seed inlet shutters open too wide

Verify setting vs., rate charts. Adjust as

need for actual seed pool.

Oil filter clogged

Replace oil filter and oil (page 22).

Magnehelic

®

gauge disconnected or

sample line(s) leaking

Check air gauging system.

Magnehelic

®

gauge uncalibrated

Re-zero (see Operator manual).

Flow control valve failure or malfunction

Repair or replace valve.

Fan seals damaged

Repair or replace fan motor.

PTO rotation and fan or valve hoses

reversed (highly unlikely)

Set tractor controls for clockwise PTO.

Reconnect hoses.

Fan cooler plugged

Clean or replace fan cooler.

Pressure correct on

Magnehelic

®

, but

skips or doubles

Pressure gauge disconnected or sample

line(s) leaking.

Check air gauging system.

Magnehelic

®

gauge uncalibrated.

Re-zero (see Operator manual).

Seed variety may require adjustment.

Check all other possible pressure errors,

then fine tune pressure for one seed per

disk cell.

Oil overheating

Oil filter clogged

Replace oil filter and oil (page 22).

PTO rpm too high

Adjust system for ideal pressure at lower

PTO rpm.

Fan butterfly valve angle too high

Reduce to 30

° (see planter Operator

manual).

Fan running in

reverse

PTO shaft turning counter-clockwise

Set tractor controls for clockwise PTO.

Hoses reversed

Check hose routing from pump to valve, to

reservoir and fan per Parts manual.

Fan doesn’t run at all

Low oil level in reservoir

Top off reservoir. Check system for leaks.

Flow control valve closed

Adjust valve (page 13).

Hoses misconnected