Reservoir on mainframe – Great Plains PTO Kits 2-3-Section User Manual

Page 44

40

2- & 3-Section YP PTO Pumps

Great Plains Manufacturing, Inc.

411-015M

2014-09-10

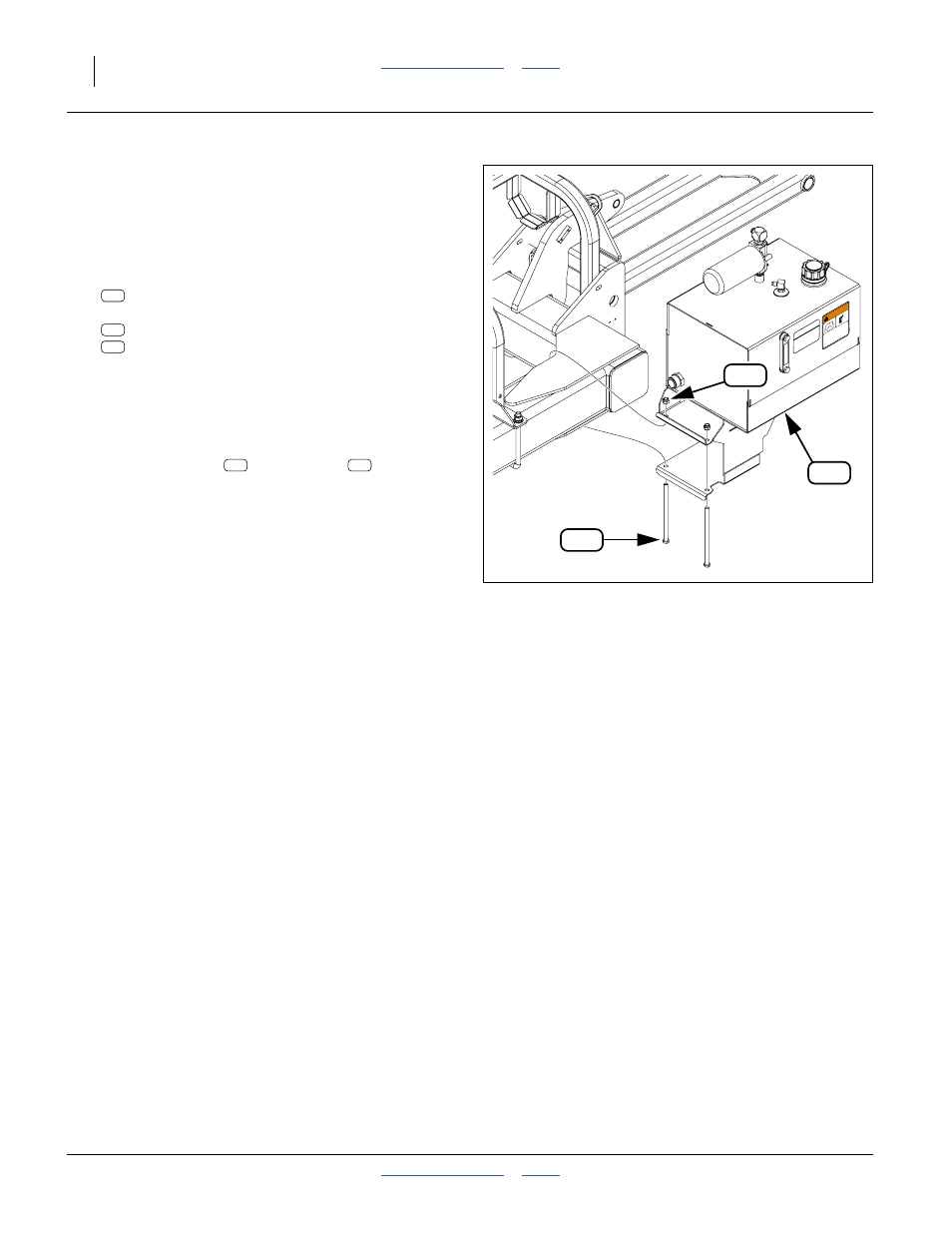

Reservoir on Mainframe

These instructions apply only to kits 401-939A,

401-940A, 401-941A and 401-942A for planter models

3PYP and 3PYPA. For other kits see the page director

table on page 39.

Refer to Figure 47

70. Select one new:

401-972L 3PYP PTO TANK ASSY

and two sets new:

802-269C HHCS 1/2-13X9 GR5

803-147C NUT HEX NYLOCK 1/2-13

71. Remove any lock channel (not shown) presently

pinned to the left rear outside of the mainframe.

72. With the decal face of the reservoir facing left, slide

the reservoir mount weldment fully right and fully

forward at the left rear corner of the mainframe.

Secure with bolts

and lock nuts

.

73. Re-pin any removed lock channel.

Continue at “Install Flow Control Valve” on page 43.

85

8-

029

C

CAP

ACITY = 13.5 U

.S

. GALS

USE ANY HIGH Q

UALITY MINERAL BASED

HYDRA

ULIC FLUID

WITH A

VISCOSITY RA

TING

OF 10W

-30.

OIL MUST BE CLEAN

A

ND FR

EE

FR

OM DIR

T

OR CON

TA

MINANT P

AR

TICLES

TO

PREVENT D

AMA

GE

T

O PUMP AND MO

TOR.

REPLA

CE FIL

TER ELEMENT AFTER EVER

Y

150 OPERA

TING HOU

RS

OR 2

YEARS SER

VICE.

LEVEL

TOOLBAR BEFORE CHEKING OIL LEVEL

OIL FILL LINE

858

-004C

Read Owner

’s Man

ual BEFORE oper

ating machine

.

Keep

tractor

at IDLING SPEED and slo

wly engage PT

O

to pre

vent damage to Hydr

aulic Motor

Keep Radiator clean and free of f

oreign matter to

pre

vent o

verheating.

Do NO

T oper

ate with h

ydr

aulic oil at or abo

ve 180°F

.

HO

T FLUID HAZARD

WARNING

148

203

211

Figure 47:

Install 3PYP/A Reservoir

36381

148

203

211

203

211