Power swing, Power swing maintenance, Power swing storage – Wheatheart X160 Series User Manual

Page 135

W

HEATHEART

- G

RAIN

A

UGERS

7. M

AINTENANCE

AND

S

TORAGE

X160-85, X160-105, X160-125

30875 R0

135

7.5. POWER SWING

7.5.1. P

OWER

S

WING

M

AINTENANCE

7.5.2. P

OWER

S

WING

S

TORAGE

T

O

PREPARE

THE

POWER

SWING

FOR

SEASONAL

STORAGE

1. Raise wheels to full up position.

2. Clean out axle assembly and lubricate chains with a light coating of oil.

3. Inspect unit for damage and note any repairs required. Order replacement

parts from your dealer.

4. Check tire pressure and inflate to 24 psi (165 kPa).

P

OST

-

STORAGE

PRE

-

OPERATIONAL

CHECKS

1. Check tire pressure and inflate according to recommendation on side wall if

necessary.

2. Keep decals clean. Replace any decal that is damaged or not clearly visible.

3. Conduct general maintenance procedure before using auger.

Important:

Use only genuine Westfield replacement parts or equivalent. Replacement parts

MUST meet ASABE standards or serious injuries may result. Use of

unauthorized parts will void warranty. If in doubt, contact Westfield or your local

Westfield dealer. Do not modify any components of the Power Swing.

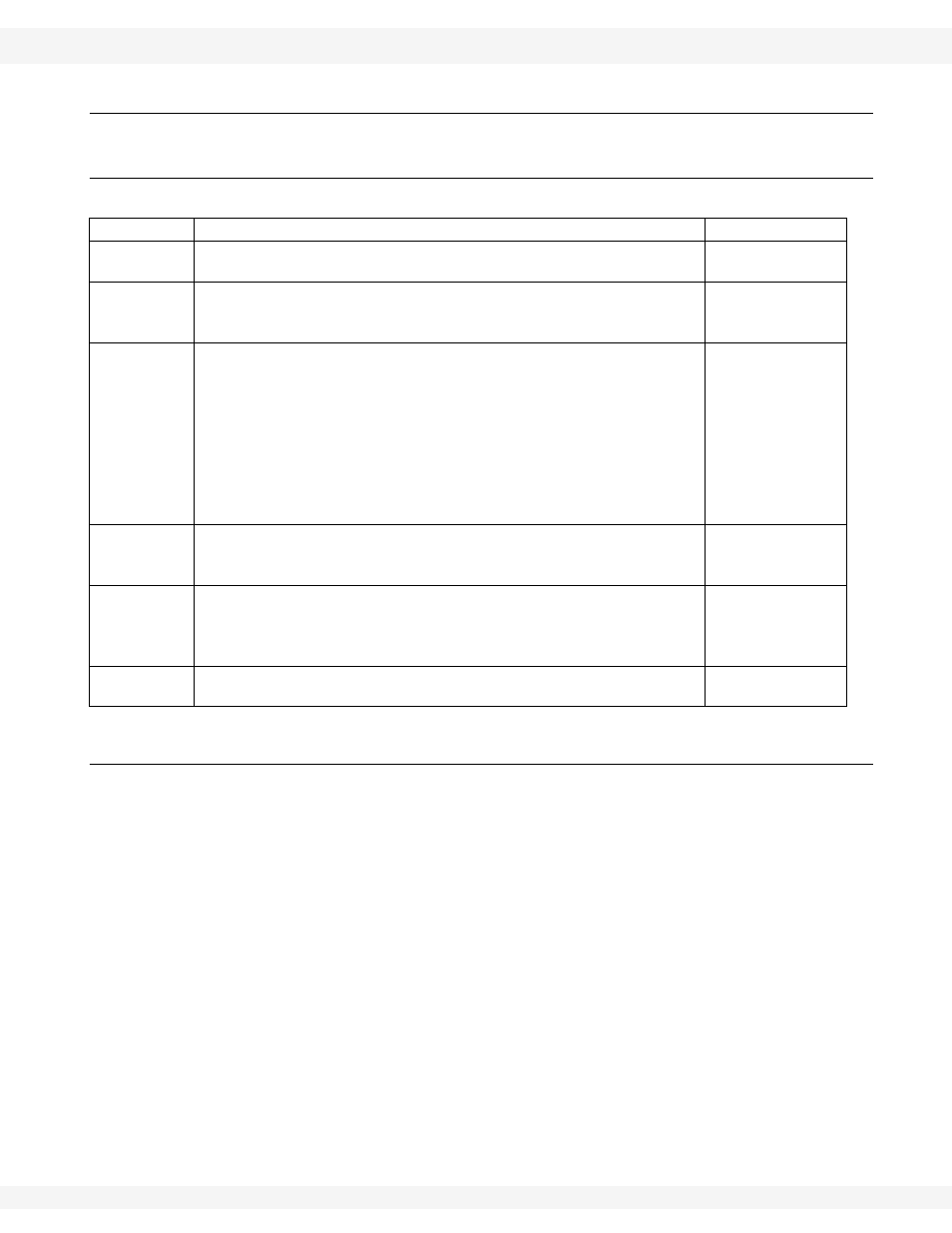

Figure 7.8 Power Swing Maintenance Schedule

Area

Maintenance Procedures

Frequency

General

While auger is in use, observe the preoperational checklist

found in the Operation section.

Daily

General

Check all operating, lifting, and transport components. Replace

damaged or worn parts before using auger. For replacement

instructions, see the Assembly section of this manual.

Regularly

Drive Chain

Keep drive chain tension adjusted to about 1/4” deflection by

loosening the 2 bolts on the hydraulic or electric motor mount,

then retighten. Apply the same procedure to the chain between

the wheels. The tension for the inter-wheel drive chain is

adjusted by loosening the two bolts on the wheel adjust plate;

re-tighten when finished.

Oil chain frequently enough to keep a light film of oil on it.

Ensure that safety guards are in place and secure before opera-

tion.

Frequently

Hydraulic

Hose

Check hose and hose couplers for leaks, wear, or damage.

Replace if necessary.

Use cardboard when searching for hydraulic leaks.

Frequently

Remote

Transmitter

Ensure that a 9V battery is installed in the back of the remote

transmitter. To install, remove the plastic from around the bat-

tery then place the battery in place in the back of the remote

control.

Before initial

operation, or as

required

Tire

Pressure

Check with a pressure gauge. It is recommended that pressure

be maintained at a maximum of 24 psi (165 kPa).

Monthly,

or as required