Wheel bolt tightening, Truss cable adjustment – Wheatheart X160 Series User Manual

Page 133

W

HEATHEART

- G

RAIN

A

UGERS

7. M

AINTENANCE

AND

S

TORAGE

X160-85, X160-105, X160-125

30875 R0

133

7.3.12. W

HEEL

B

OLT

T

IGHTENING

1. Clean wheel and hub mounting

surfaces to ensure there is no rust or

debris.

2. Inst all the wheel and finger-tighten the

wheel bolts. Inspect to make sure the

wheel is sitting flush with the hub.

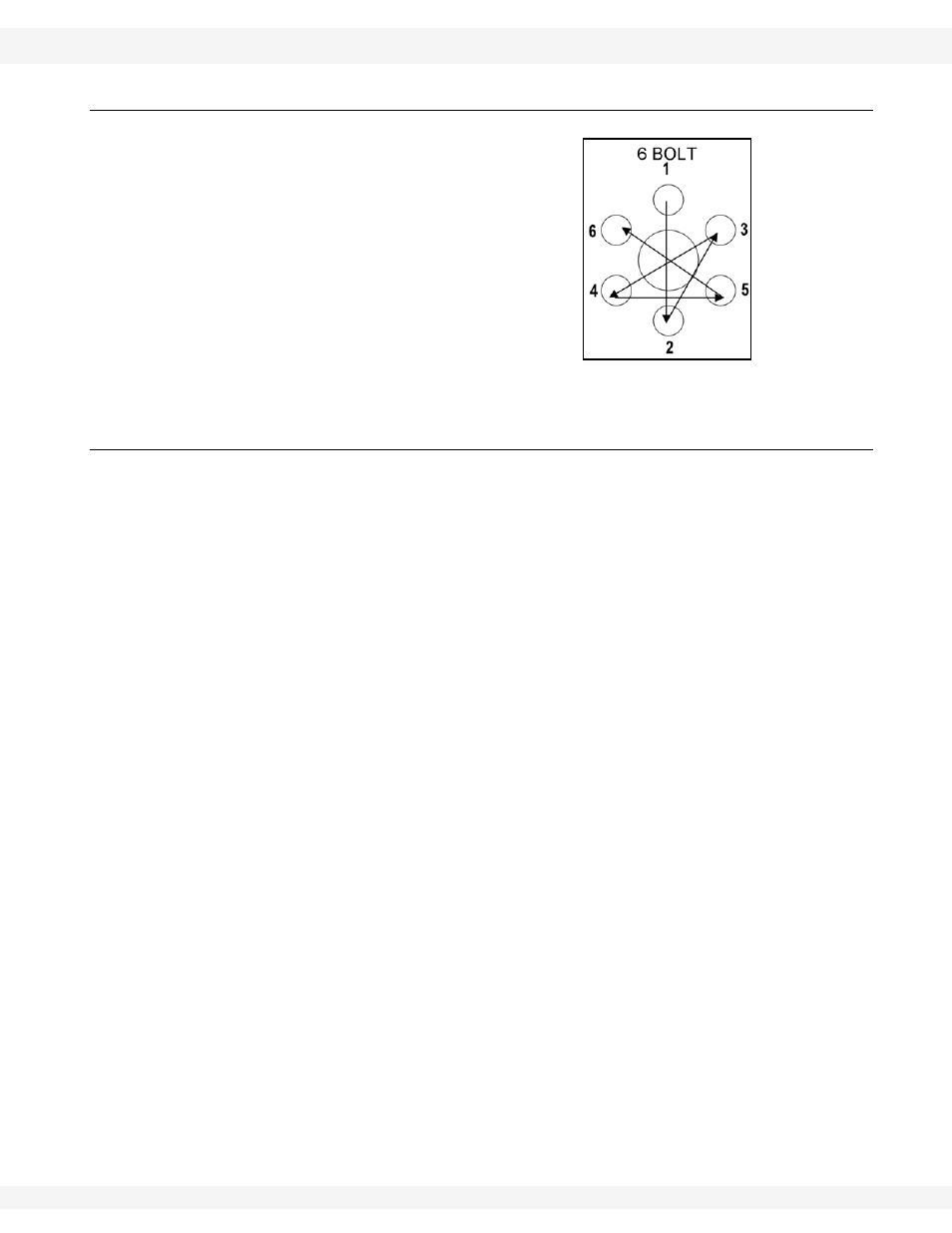

3. T ighten the wheel bolts with a torque

wrench to 80 ft-lb (±10 ft-lb) of torque.

Tighten the wheel bolts in a diagonal

pattern as shown in Figure 7.7.

7.3.13. T

RUSS

C

ABLE

A

DJUSTMENT

The cables are properly tightened when:

• There is no slack in the cables.

• The discharge end is deflected sightly upwards.

• The tube is straight side-to-side.

T

IGHTENING

C

ABLES

The location of the cable adjustment points are shown in the accompanying

figure.

1. Lift the discharge end of the auger with a front end loader so that the tube

has a slight upward deflection at the discharge to give the cable some slack.

2. Tighten the left-side and right-side eyebolts equally to increase the tension in

the cable (use eyebolt nuts to tighten eyebolts).

3. If the proper cable tension can’t be obtained before the eyebolts run out of

adjustment, then do the following:

a. Loosen the eyebolts.

b. At the eyebolts, loosen the cable clamps, shorten the cables until there is

tension on the cable, then tighten the cable clamps fully.

S

TRAIGHTENING

T

HE

T

UBE

1. If the tube is sagging at the discharge:

• Lift the discharge end of the auger with a front end loader or rest on a bin

so that the tube has a slight upward deflection at the discharge to give the

cable some slack.

• Tighten the eyebolts evenly on both sides so the tube stays straight.

• Tighten the cables so there is a slight upwards angle on the discharge

end.

• Check the short cable for slack and tighten as necessary.

Figure 7.7 Crisscross Pattern

Note: